You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wrist Blade Gauntlet (functional)

- Thread starter MasterAnubis

- Start date

MasterAnubis

Sr Member

I did cover that in my first posting.

The total thickness is 1/4". I find that to be a really good thickness to keep thing flexable and not too brittle. When they get too thick they could tend to break rather than bend when snagged on things.

-Shawn

I'm using 1/8"(.125") ABS plastic because I have a whole sheet of this stuff.

Going off of this reference pic, I drew up my blades.

I made two templates using manila folder. One was made to be like the pic and the other is shorter and straight to facilitate the movement without being so damn long.

I made a plastic template so that I could have a more permanent template. Not that that matters, the folder paper lasts a while if it's not abused.

I cut my 15" X 2" stripes and glued them into pairs to double up the thickness to get to 1/4". Then taped them all together and traced out the blades.

The total thickness is 1/4". I find that to be a really good thickness to keep thing flexable and not too brittle. When they get too thick they could tend to break rather than bend when snagged on things.

-Shawn

Last edited by a moderator:

Daeros

New Member

Omg!!! i had my breakthrought now when i readed your reply carefully: I cut my 15" X 2" stripes and glued them into pairs to double up the thickness to get to 1/4". Then taped them all together and traced out the blades. You did glued them togethor  i am stationed in sweden i have looked for ABS plastic in 3 days now found one 2 days ago but that was only 1.5 mm thick so i needed to look for anothor and i didnt found a thicker but to glue them togethor! i didn´t even have a thought. Man you are trueley the blade guy

i am stationed in sweden i have looked for ABS plastic in 3 days now found one 2 days ago but that was only 1.5 mm thick so i needed to look for anothor and i didnt found a thicker but to glue them togethor! i didn´t even have a thought. Man you are trueley the blade guy

Last edited by a moderator:

MasterAnubis

Sr Member

Ha! Thanks.Man you are trueley the blade guy

Another reason to glue then together is that I got the “haircell” type of general purpose sheet. That means one side is textured. So, I glue the textured sides together and then don’t have to worry about it.

MasterAnubis

Sr Member

I was going to say check out my profile, I list my major builds there. The only other piece quite like this is my timer gauntlet.

http://www.thehunter...timer-gauntlet/

and it's not truly done even though I were it. (The armor I've made was sclupted, molded then cast.)

You may get a lot out of these threads

http://www.thehunterslair.com/topic/24670-big-evils-big-celtic/

http://www.thehunterslair.com/topic/10450-avp-armor-templates-by-vinman/

http://www.thehunter...timer-gauntlet/

and it's not truly done even though I were it. (The armor I've made was sclupted, molded then cast.)

You may get a lot out of these threads

http://www.thehunterslair.com/topic/24670-big-evils-big-celtic/

http://www.thehunterslair.com/topic/10450-avp-armor-templates-by-vinman/

TitanPredator

New Member

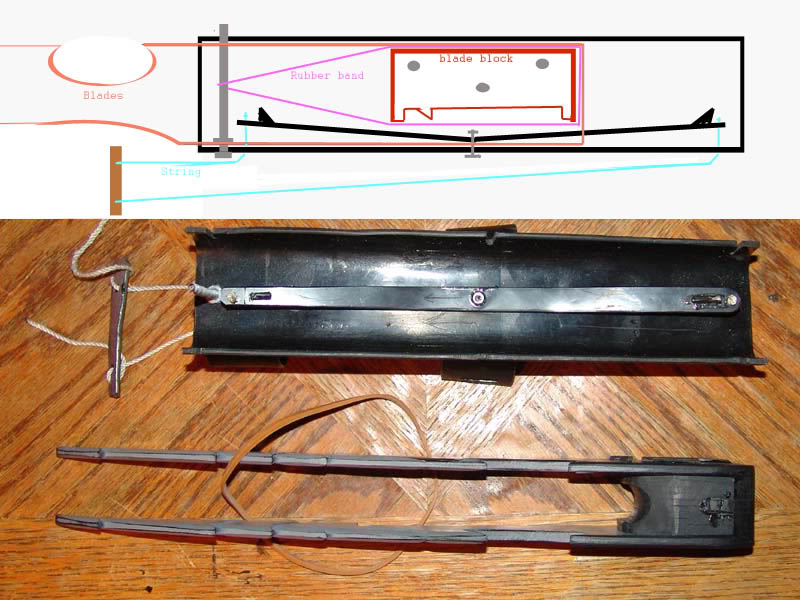

The main tube and blades are made from 1/8" ABS. The blades are two pieces laminated together to eliminate the hair cell from showing.

Most of this wasn't really measured, it was cut to fit.

The blade assembly is 1-5/8"W x 2"H

The I.D. of the launch tube is 1-7/8"W and 2-1/8"H

The tubes length is now 11.5"

The blade length is just shy of 15"

So the overall length when retracted it 15"

Extended it's 23.25"

-So it has a 8.25" stroke-

The top cover was rounded over for looks and the blade block was rounded to match it. The U shape cutout was so that it could go another 1/4" further out and I add a second catch on the front because of this.

Because of the way I folded the plastic it radiased a little more than I inteded and therefore I had to have more space either on top or on the sides. I left it on the sides. This allows for free unbound movement. I added small things I'm calling guide spacers that take up the wobble when fully extended. They aren't need when retracted because of the rubber band tension.

The two issues I've been trying to minimize are the binding on the rubberband and the rubberband herniating forward. With loose tolerances the binding is gone and I have the rubberband tethered to the middle near the screw to minimize the herniation.

Does that awnser your questions on this, or where you looking for screw sizes and stuff?

Master Anubis first off I want to congratulate you on a fantastic job on those blades & gauntlet as well as thank you for giving me a better idea on how to do mine, I was almost going to just make mine stationary but then I knew that if I did, I would not be happy with the reuslts at all. Secondly and I didn't see it posted anywhere, would the rubberband problem cease if you put two bolts like the stop one a couple inches back from the stop bolt on the sides so they don't touch the blades? I am going to be using your idea because it not only looks great but it's easy & no electrical wiring needed.

MasterAnubis

Sr Member

Thanks.

If I'm understanding you right about the two bolts, I don't think so. Anything else in the tube may end up as a snag hazard for the blades.

What I've found out in the practical setting is that the rubber band isn't really necessary and even if it pops out, it’s not that big of a deal. The blades slide perfectly with out the rubber band and I think I may just run without it now and let gravity do the work.

The two problems I’ve had while in costume have been the rubber band moving and coming off the blade block and the pull string wearing through on the front lock. The rubber band part was fixable easily enough during a break. The front string breaking was annoying but it meant that the blades were locked out(which was OK). The string rubbed through at the front screw. I think a small tube will help eliminate that.

If I'm understanding you right about the two bolts, I don't think so. Anything else in the tube may end up as a snag hazard for the blades.

What I've found out in the practical setting is that the rubber band isn't really necessary and even if it pops out, it’s not that big of a deal. The blades slide perfectly with out the rubber band and I think I may just run without it now and let gravity do the work.

The two problems I’ve had while in costume have been the rubber band moving and coming off the blade block and the pull string wearing through on the front lock. The rubber band part was fixable easily enough during a break. The front string breaking was annoying but it meant that the blades were locked out(which was OK). The string rubbed through at the front screw. I think a small tube will help eliminate that.

UnitedHerps

New Member

pretty cool, i really dig it!!!

Pitoon

Pitoon

TitanPredator

New Member

Thanks.

If I'm understanding you right about the two bolts, I don't think so. Anything else in the tube may end up as a snag hazard for the blades.

What I've found out in the practical setting is that the rubber band isn't really necessary and even if it pops out, it’s not that big of a deal. The blades slide perfectly with out the rubber band and I think I may just run without it now and let gravity do the work.

The two problems I’ve had while in costume have been the rubber band moving and coming off the blade block and the pull string wearing through on the front lock. The rubber band part was fixable easily enough during a break. The front string breaking was annoying but it meant that the blades were locked out(which was OK). The string rubbed through at the front screw. I think a small tube will help eliminate that.

you know what? I was seeing it wrong, I'm sorry, I wonder if a little u-bolt of some sort on the stop bolt would work? Well I'm heading over to Lowe's tomorrow and see what I can find, thank you very much for this post because I was racking my brain on how to make retracible blades without making it too difficult

TitanPredator

New Member

I just got my 12"x12" piece of 1/8" black ABS plastic in the mail since I attempted to make a tubing out of two pieces of door draft eliminator but I wasn't happy with the resuts so I found ABS on ebay, pretty expensive stuff for the size. My question is what method did you use to make the tubing? I already made the blades out of 1/4" plexi glass which was easily available at Lowe's home Improvement. Thanks for this great tutorial

thomason27

New Member

Hey I found your hunters lair stuff now I will do some studying of it and then hopefully have one of my own. If I have any questions I will ask you here.

Dreamdemon

New Member

Hey, I've been looking for something like this for years now,then today I find your video on YouTube today. I was wondering if you could make an actual how to video and post it on your YouTube channel? I hope you read this. Thank you for your time.So my helmets progress was slowed and I got sidetracked by blades...

EDIT: This is the scaled up version of my son's proof of concept: Predator Costumes and Props

I'm using 1/8"(.125") ABS plastic because I have a whole sheet of this stuff.

Going off of this reference pic, I drew up my blades.

View attachment 1175136

I made two templates using manila folder. One was made to be like the pic and the other is shorter and straight to facilitate the movement without being so damn long.

I made a plastic template so that I could have a more permanent template. Not that that matters, the folder paper lasts a while if it's not abused.

I cut my 15" X 2" stripes and glued them into pairs to double up the thickness to get to 1/4". Then taped them all together and traced out the blades.

View attachment 1175137

I band sawed out the shape then clamped them into the vise and filed them down to match each other.

Once I had them separate I filed and roto-tooled them to detail them to resemble the reference pic. I rounded all of the edges and beveled the edges. Overall I'm not thrilled with the way they came out and I have some touch ups to do before I paint them.

View attachment 1175138

This is the lot of blades.

View attachment 1175139

.

View attachment 1169416

View attachment 1169417

View attachment 1169418

View attachment 1169420

Dreamdemon

New Member

Can you please make a video of how to build it and put it on YouTube?I got some good progress done in the last few days. Slow going but ever forward...

I mated the blades with the block to hold them together and now they are a sub assembly. I formed the top and bottom of the action tube and have it screwed together. I have a temporary rubber band in it so that I can test the fit and function of the latch. I still need to finish shaping the tube and then I can start on the decorating it and turning it into a gauntlet.

The sub assemblies:

View attachment 1175133

them together:

View attachment 1175134

the action:

View attachment 1175135

I'll post a better video after I get is edited.

View attachment 1169413

View attachment 1169414

View attachment 1169415

MasterAnubis

Sr Member

Hi, Sorry for the delayed response. Well basically, if I say I'll do a video it would probably be a while. I've always taken tutorials too seriously. That's why I did as good of drawings as I could do at the time and described it the best I could.

This may be as good of time as any to at least try an update... it would be slow. I've been using these blades almost unchanged since then. There are some small revisions for comfort and function.

My techniques are a little antiquated by todays "3d Print everything" culture that seams to be in vogue. I'll PM you with some questions so that I can get a feel for what you're after.

-Shawn

This may be as good of time as any to at least try an update... it would be slow. I've been using these blades almost unchanged since then. There are some small revisions for comfort and function.

My techniques are a little antiquated by todays "3d Print everything" culture that seams to be in vogue. I'll PM you with some questions so that I can get a feel for what you're after.

-Shawn

Similar threads

- Replies

- 0

- Views

- 303

- Replies

- 0

- Views

- 157

- Replies

- 10

- Views

- 435