You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wrist Blade Gauntlet (functional)

- Thread starter MasterAnubis

- Start date

MasterAnubis

Sr Member

Thanksmy god, they turned out f*?king fabulous dude, well done

Well... It is painted. It started life out as black plastic. I'm blaming the lighting for the colors not coming out stronger. The aluminum doesn't like the flash and I was real light on the accents. I was worried that I was going to over do it. I'm still considering adding more black accents and highlights.Wow...That looks amazing, just need to paint it up

Are you gonna be making and selling these?

Thanks

I have updated my last post (#19) with the video links..

Thanks to everyone following this.

Nismo300ZX

New Member

As time consuming as it would be, I still think you could sell a ton of these. I definitely would buy one right this second. Awesome!

Didact

New Member

I second that., I would really be interestedAs time consuming as it would be, I still think you could sell a ton of these. I definitely would buy one right this second. Awesome!

shockwave1

New Member

Awesome work, can't wait to see what you do with the rest of your suit!

stopeverything

Well-Known Member

OH MY GOD. Thats freaking awesome. Would you do a commission if I BEGGED?

leatherneck

Well-Known Member

That is pretty sweet. Great work!!

Naasad Tal

Well-Known Member

GREAT WORK MAN!!!

You've really done it now...EVERYONE is gonna keep buggin you till you start cranking these things out...BTW the way I assume mine got lost in the mail

again great work man the gaunt looks baddASS

Chris

You've really done it now...EVERYONE is gonna keep buggin you till you start cranking these things out...BTW the way I assume mine got lost in the mail

again great work man the gaunt looks baddASS

Chris

Demascus

New Member

They may not retract but they have all the rest of the functionality covered. They not only work, they look fairly well made and comfortable. No complaints here those are absolutely awesome! Inspiring work...I just wish I totally understood how it worked so I could do it myself. *L*

MasterAnubis

Sr Member

wow....

Thank you all!

With such a great responce, I guess I will just have to look into making more. I'll have to see what I can come up with . It would be nice to see my creations out and about.

You know, I still have the other gauntlet to make too. At this rate I may just consider dual blade gauntlets.

At this rate I may just consider dual blade gauntlets.

Thank you all!

With such a great responce, I guess I will just have to look into making more. I'll have to see what I can come up with . It would be nice to see my creations out and about.

You know, I still have the other gauntlet to make too.

MasterAnubis

Sr Member

Thanks!Well done sir

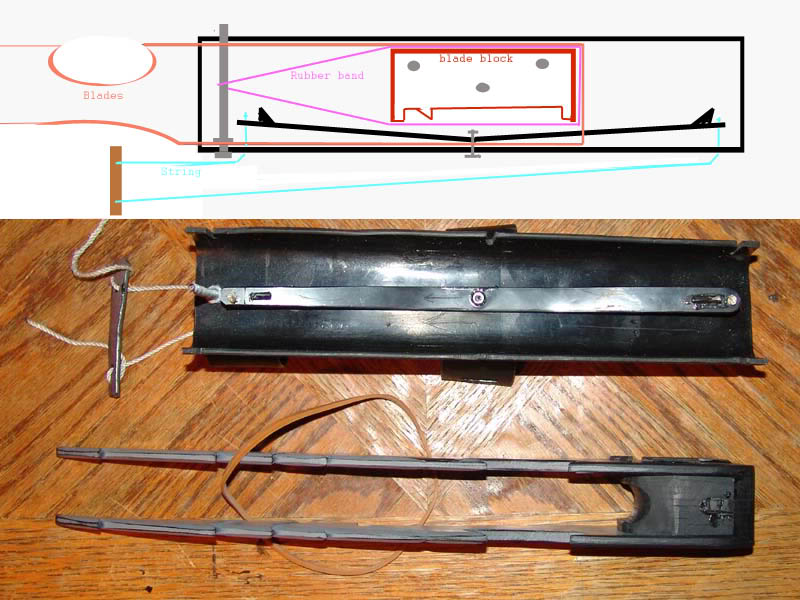

Sure thing, I'll draw something up today. This is scalable. My original proof of concept was my kids version:Finally someone has created a simple, inexpensive and practical gauntlet blade mechanism. Hat's off to you. Any chance you could post up a schematic with material call outs on how to build one of these?

http://www.thehunterslair.com/index.php?showtopic=15423

The smaller version breakdown should help visualize it.

MasterAnubis

Sr Member

Finally someone has created a simple, inexpensive and practical gauntlet blade mechanism. Hat's off to you. Any chance you could post up a schematic with material call outs on how to build one of these?

The main tube and blades are made from 1/8" ABS. The blades are two pieces laminated together to eliminate the hair cell from showing.

Most of this wasn't really measured, it was cut to fit.

The blade assembly is 1-5/8"W x 2"H

The I.D. of the launch tube is 1-7/8"W and 2-1/8"H

The tubes length is now 11.5"

The blade length is just shy of 15"

So the overall length when retracted it 15"

Extended it's 23.25"

-So it has a 8.25" stroke-

The top cover was rounded over for looks and the blade block was rounded to match it. The U shape cutout was so that it could go another 1/4" further out and I add a second catch on the front because of this.

Because of the way I folded the plastic it radiased a little more than I inteded and therefore I had to have more space either on top or on the sides. I left it on the sides. This allows for free unbound movement. I added small things I'm calling guide spacers that take up the wobble when fully extended. They aren't need when retracted because of the rubber band tension.

The two issues I've been trying to minimize are the binding on the rubberband and the rubberband herniating forward. With loose tolerances the binding is gone and I have the rubberband tethered to the middle near the screw to minimize the herniation.

Does that awnser your questions on this, or where you looking for screw sizes and stuff?

MasterAnubis

Sr Member

No prob. The kids version I made was also made of 1/8" ABS. I really like ABS, it just takes more heat to shape. I'm planning on remaking the kids version in Sintra to see if the softer plastic will work. Sintra is much easier to work and carve.Very nice design if you don't mind I will you the scaled down one for my little guy's suit.

Ei luj

New Member

The two issues I've been trying to minimize are the binding on the rubberband and the rubberband herniating forward. With loose tolerances the binding is gone and I have the rubberband tethered to the middle near the screw to minimize the herniation.

Does that awnser your questions on this, or where you looking for screw sizes and stuff?

MasterAnubis,

In regards to rubberband herniation, how would it be different if a spring were used instead of the rubber band?

Thats what I have in mine (no catch yet, good job on yours )

---

Ei'luj

Similar threads

- Replies

- 0

- Views

- 241

- Replies

- 0

- Views

- 117

- Replies

- 9

- Views

- 358