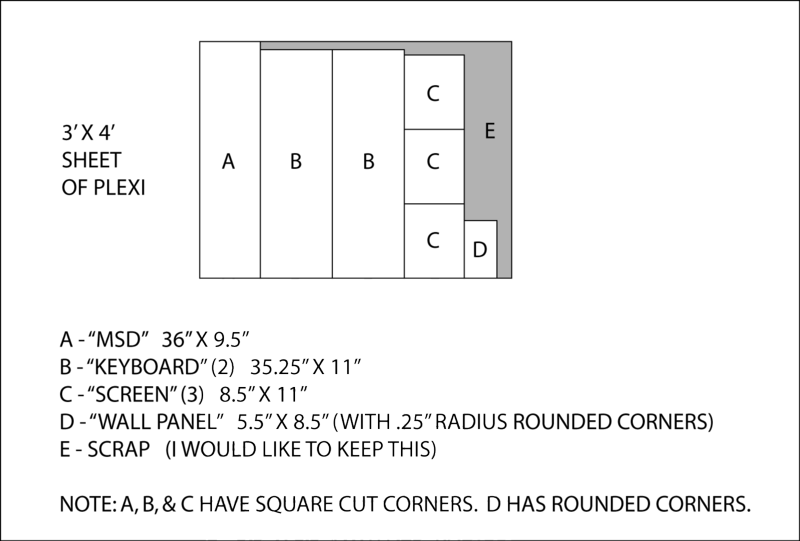

Making some LCARS panels and a few odds and ends from a big sheet of 1/8" thick plxi.

I have had no sucess with scoring and breaking. I was wondering about trying a band saw, or is there something else? I'd like to be able to make some good clean cuts with as little clean up as possible.

FYI: Some pieces will be small like 3/4" x 3" but other pieces will be as big as 1' x 3'.

Any ideas?

I have had no sucess with scoring and breaking. I was wondering about trying a band saw, or is there something else? I'd like to be able to make some good clean cuts with as little clean up as possible.

FYI: Some pieces will be small like 3/4" x 3" but other pieces will be as big as 1' x 3'.

Any ideas?