You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Warehouse 13 - The Tesla Gun

- Thread starter Kylash

- Start date

Dakarn

Well-Known Member

I'm just a bit concerned about breakage in a con setting but I think I'm just going to leave them alone and buy a few replacements. I'll be drilling out the holes for the pins like the original prop, thats the most stable way to mount the tube. I was originally thinking of socket mounting it but drill + drill press = easier.

I found this at Lowes this evening while browsing for bath tub drains. With a little trimming and paint that part is close to being done.

I found this at Lowes this evening while browsing for bath tub drains. With a little trimming and paint that part is close to being done.

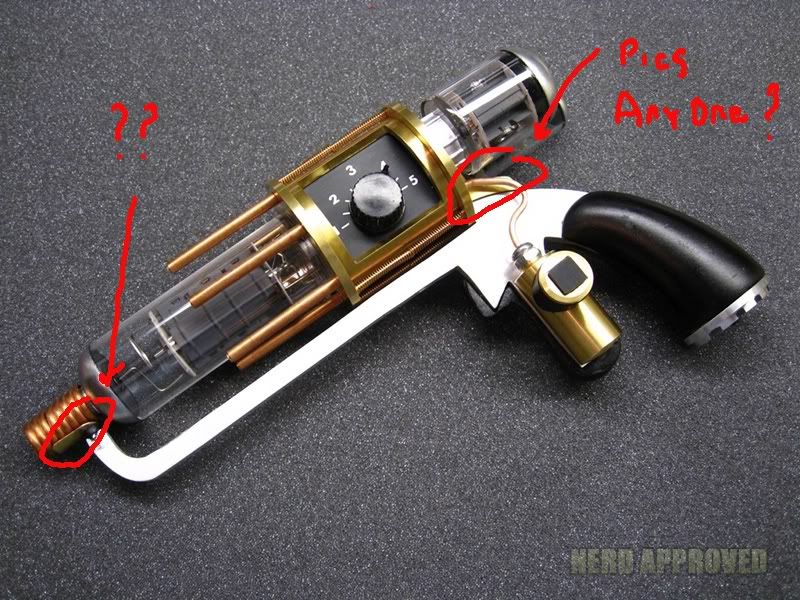

Can someone help and tell me what these parts are?

The front piece seems to be just a thin, slightly curved piece of copper that's soldered on... seems to be mostly rectangular with rounded corners at the front and the whole back rounded into a semi-circle, with the whole thing bent to the curvature of the wound copper "barrel." I've always assumed it to be a custom piece. It's also pretty fragile, as one of the screen-used Teslas was auctioned off and that piece went all wavy, as you can see below:

For the back piece, I have some reference pics that were taken by another member here of the screen-used piece that was auctioned (the above is from that same set). They were posted earlier in the thread, but as it's so long, I thought I'd just post the ones I downloaded:

Hope those help... it's a hard part to get a good shot of, but those should give you a good idea. And props to whoever it was that took the pics in the first place!

Last edited:

kcpstudio

Sr Member

Hi Timelordd,

First.... boy you guys don't mess around with getting pics of the heros. LOL

OK... timelordd... If you look at the pics closely, you'll be able to make it out. The front piece is a piece of copper I used. I cut it to shape and then curled it a little to match the radius of the coil. Now... this copper got a little beat up so it looks very wavy. If you look at pics of the one I made for QMX, you'll see that it isn't wavy at all. This is exactly how I made the studio guns. It should look very clean and sharp. Just put a slight radius on the corners and get as close as you can to mine and you'll be fine. Then I soldered it to a flat head screw. The connection between the coil and this curled copper is epoxy. The back section piece is custom shape etc and I machined that out of brass and is what connects the back end of the upper assembly to the lower frame. Now, I can't provide drawings or CAD of these parts but I think with what you've been doing so far, you'll be fine. I fish I could be more help but NDA is a knocking on the door. One other point I would like to make. This gun, even though it was a hero, did not have the aluminum machined lower butt plate on the grip. The one you see in the pic is cast from a mold off the hero that did have the aluminum machined part. To be accurate.... machine it out of alluminum. Again, I can't provide details on the CAD or give drawings out but I think you'll be fine with pics off the net. Just zoom in on the pics and I think you can make out the details.

Sorry I couldn't be more help.

Kenney

First.... boy you guys don't mess around with getting pics of the heros. LOL

OK... timelordd... If you look at the pics closely, you'll be able to make it out. The front piece is a piece of copper I used. I cut it to shape and then curled it a little to match the radius of the coil. Now... this copper got a little beat up so it looks very wavy. If you look at pics of the one I made for QMX, you'll see that it isn't wavy at all. This is exactly how I made the studio guns. It should look very clean and sharp. Just put a slight radius on the corners and get as close as you can to mine and you'll be fine. Then I soldered it to a flat head screw. The connection between the coil and this curled copper is epoxy. The back section piece is custom shape etc and I machined that out of brass and is what connects the back end of the upper assembly to the lower frame. Now, I can't provide drawings or CAD of these parts but I think with what you've been doing so far, you'll be fine. I fish I could be more help but NDA is a knocking on the door. One other point I would like to make. This gun, even though it was a hero, did not have the aluminum machined lower butt plate on the grip. The one you see in the pic is cast from a mold off the hero that did have the aluminum machined part. To be accurate.... machine it out of alluminum. Again, I can't provide details on the CAD or give drawings out but I think you'll be fine with pics off the net. Just zoom in on the pics and I think you can make out the details.

Sorry I couldn't be more help.

Kenney

kcpstudio

Sr Member

No problem timelordd.....

Just look at the above photos close enough and you should see the profile shape of the rear brass part you questioned about. I think your hardest part you'll have to work on will be the front coil. When I made the studio guns, I had to machine a custom jig to create the coil. Now, the studio guns get beat during shooting so you have to look at the ones I made for QMx to see the crisp shape of the coil.

Keep going man.... looks good.

Just look at the above photos close enough and you should see the profile shape of the rear brass part you questioned about. I think your hardest part you'll have to work on will be the front coil. When I made the studio guns, I had to machine a custom jig to create the coil. Now, the studio guns get beat during shooting so you have to look at the ones I made for QMx to see the crisp shape of the coil.

Keep going man.... looks good.

PeterLC

Sr Member

No she won't. Here is the reponse.

"The insides are printed, not a working model. If I tore out two of the printed insides to sell you, I would be left with two shell bodies that are junk. I do not have extras of the printing inside, sorry. You would have to actually purchase the items."

"The insides are printed, not a working model. If I tore out two of the printed insides to sell you, I would be left with two shell bodies that are junk. I do not have extras of the printing inside, sorry. You would have to actually purchase the items."

It's a jewelry item on eBay:lol. Weston Meter Jewelry. Contact the maker and he might sell you a few of the dials!

Last edited by a moderator:

No she won't. Here is the reponse.

"The insides are printed, not a working model. If I tore out two of the printed insides to sell you, I would be left with two shell bodies that are junk. I do not have extras of the printing inside, sorry. You would have to actually purchase the items."

So basically what she's saying is she's a reseller and not the person that makes the items. :thumbsdown That sucks.

Last edited by a moderator:

division 6

Master Member

Page 15

Zaphod

Sr Member

Thanks division 6.

I want one of these.

Anyone know what tubes go into this?

Timelordd, do you mind if i ask how thick you made your frame? I am thinking about tackling one of these in the near future.

Thank you!!

PeterLC

Sr Member

I thought exactly the same thing. Still, someone must have made the things. Having said that, it should still be one of the easier things on the prop to make if it is just a picture. I think print the scale but make a tiny needle (etched brass) for it so it has depth. Perfection (font DPI etc) may not be attainable but it is so small that no one is likely to notice.

Timelord's work has made me think twice about even attempting this.

Timelord's work has made me think twice about even attempting this.

So basically what she's saying is she's a reseller and not the person that makes the items. :thumbsdown That sucks.

Looking good timelordd!

Similar threads

- Replies

- 20

- Views

- 3,314

- Replies

- 31

- Views

- 2,985

- Replies

- 27

- Views

- 4,557

- Replies

- 19

- Views

- 3,290