SteveNeill

Sr Member

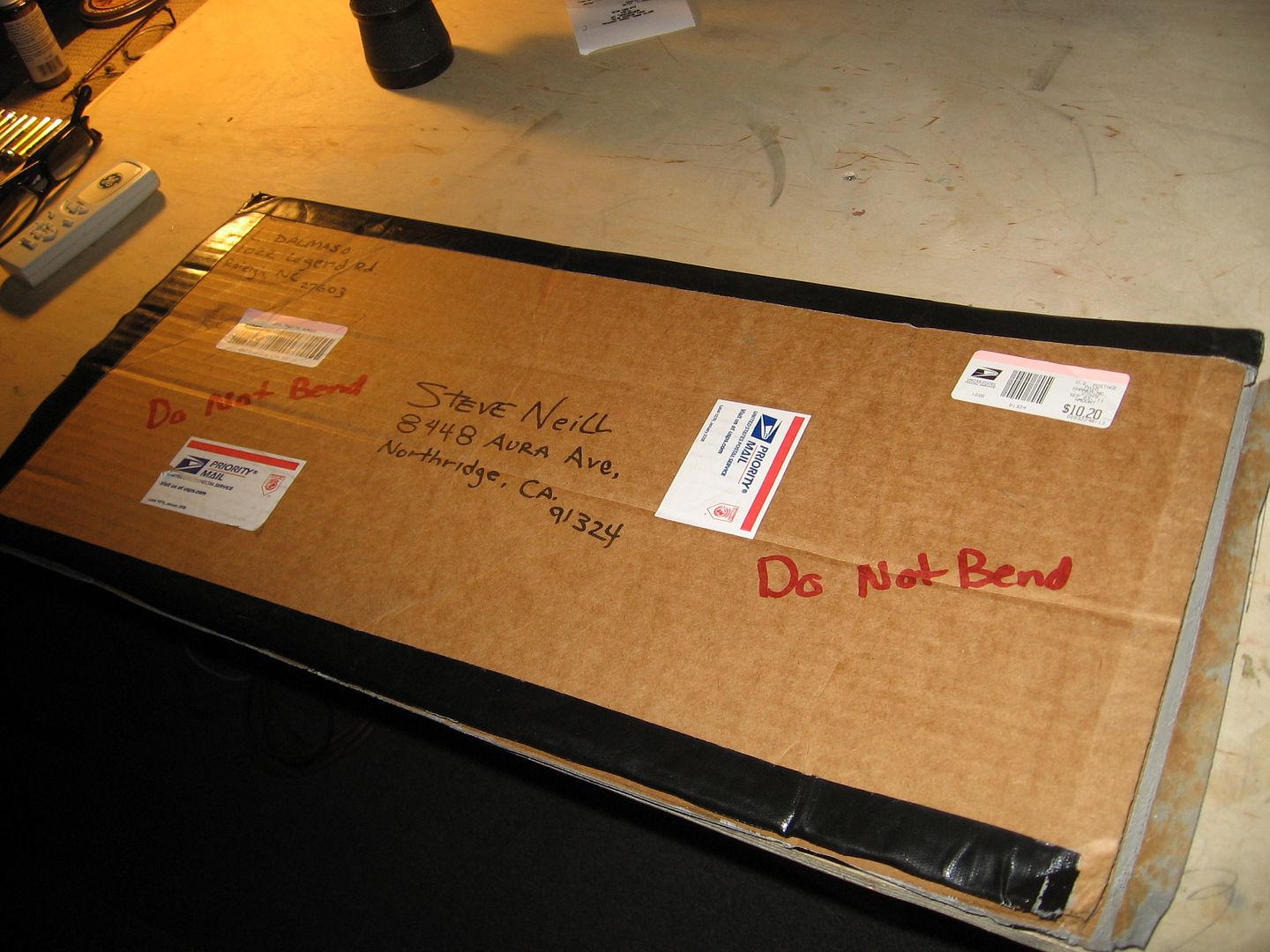

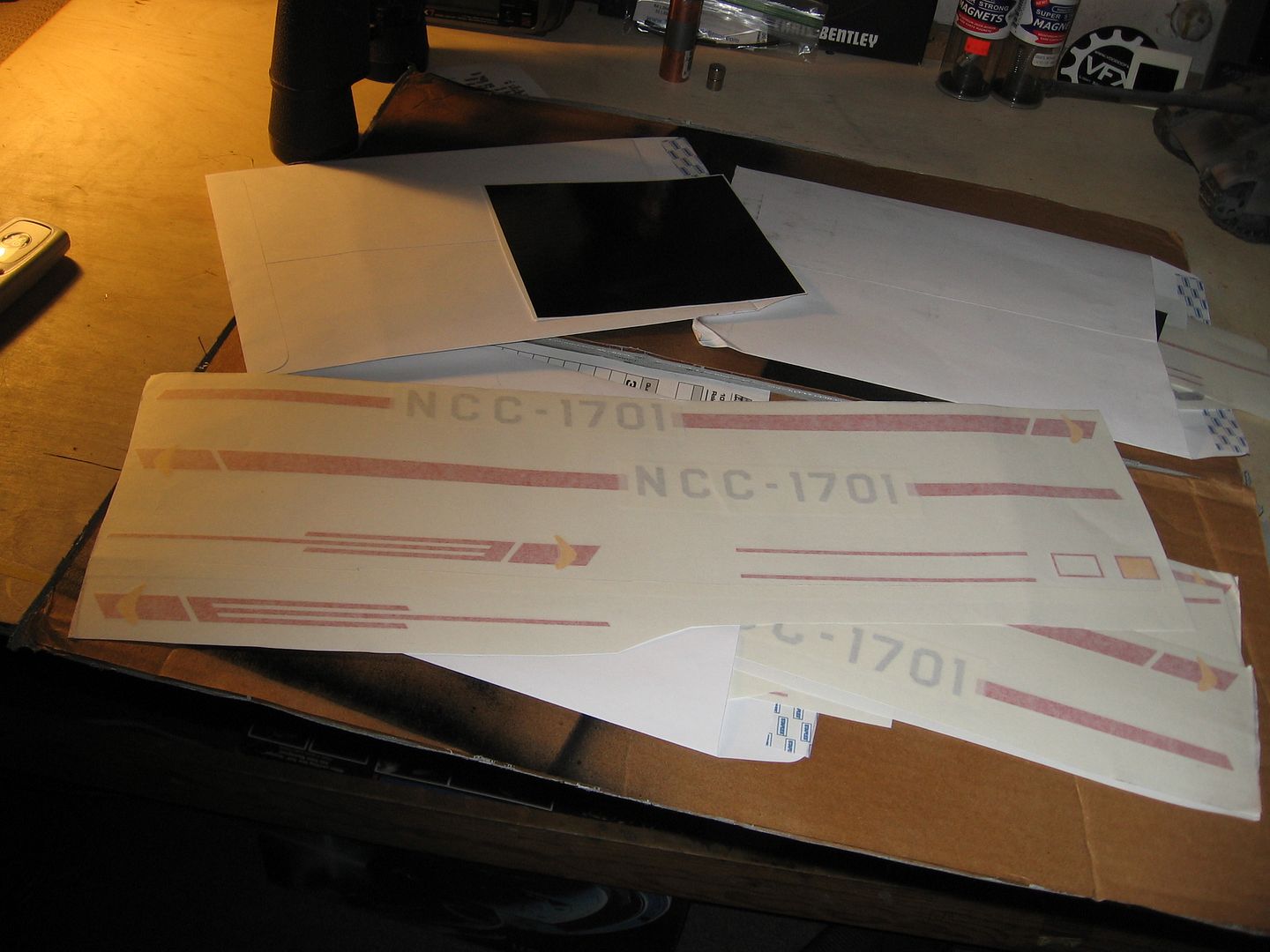

I forgot to mention and do not bend package showed up today from the very reliable and forth coming Aztek Dummy. They are in a word, "Excellent!!!" Wow!

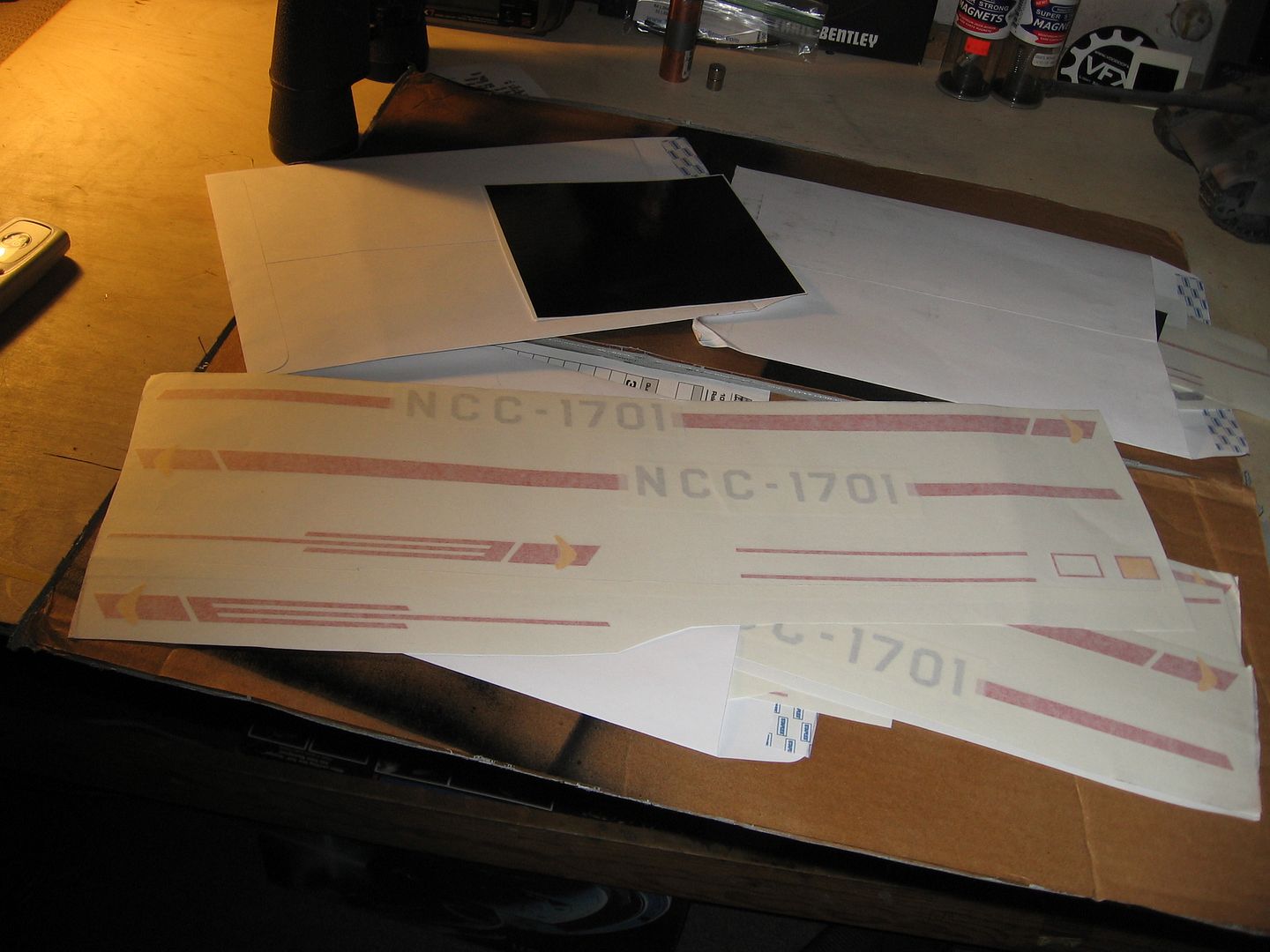

Yes the Enterprise's vinyl decals. Lou you rock! These are the biggest decals I have ever worked with. The package was marked don't bend but they did it anyway. Seems to me they are the dummies but all is well.

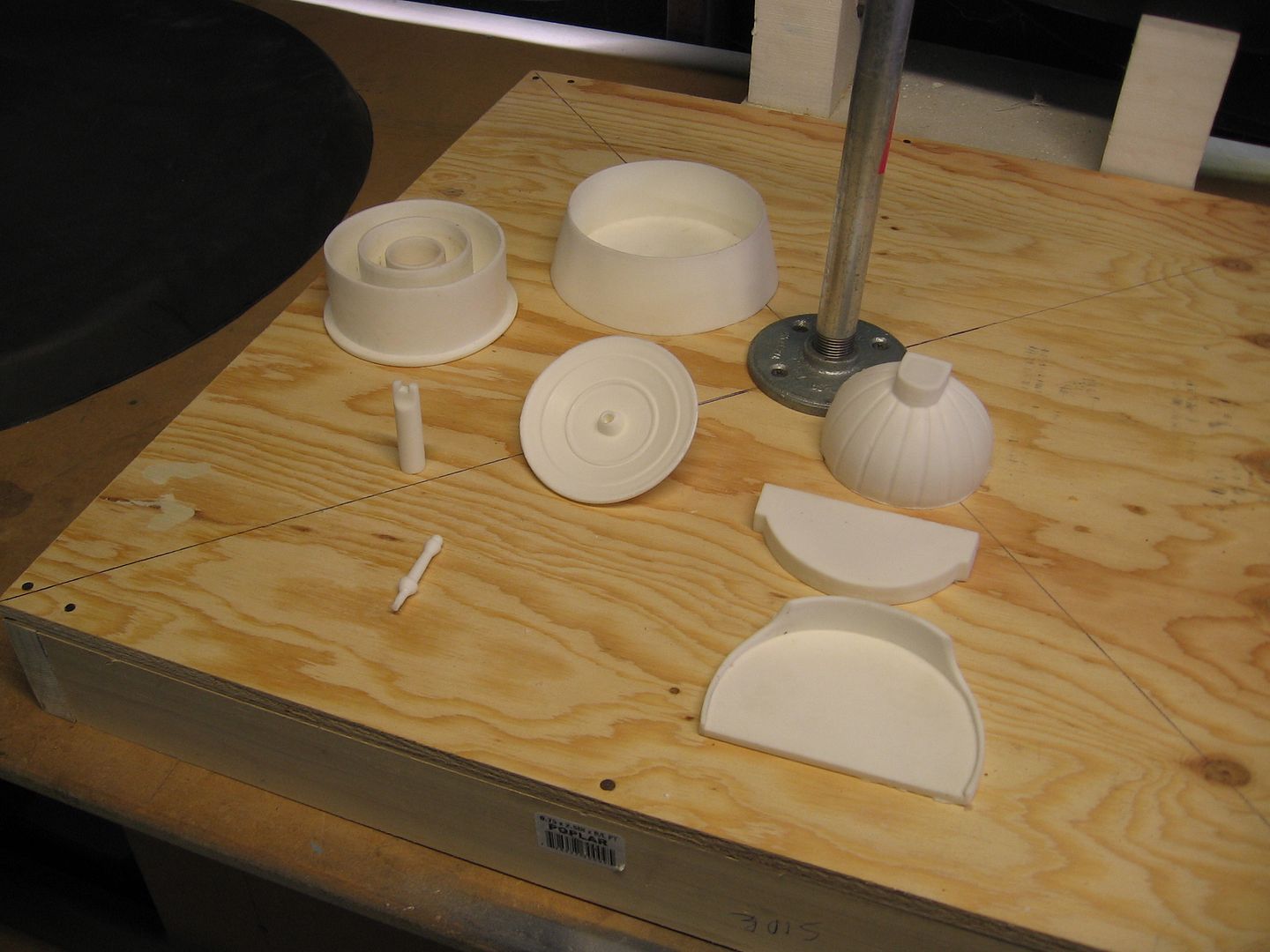

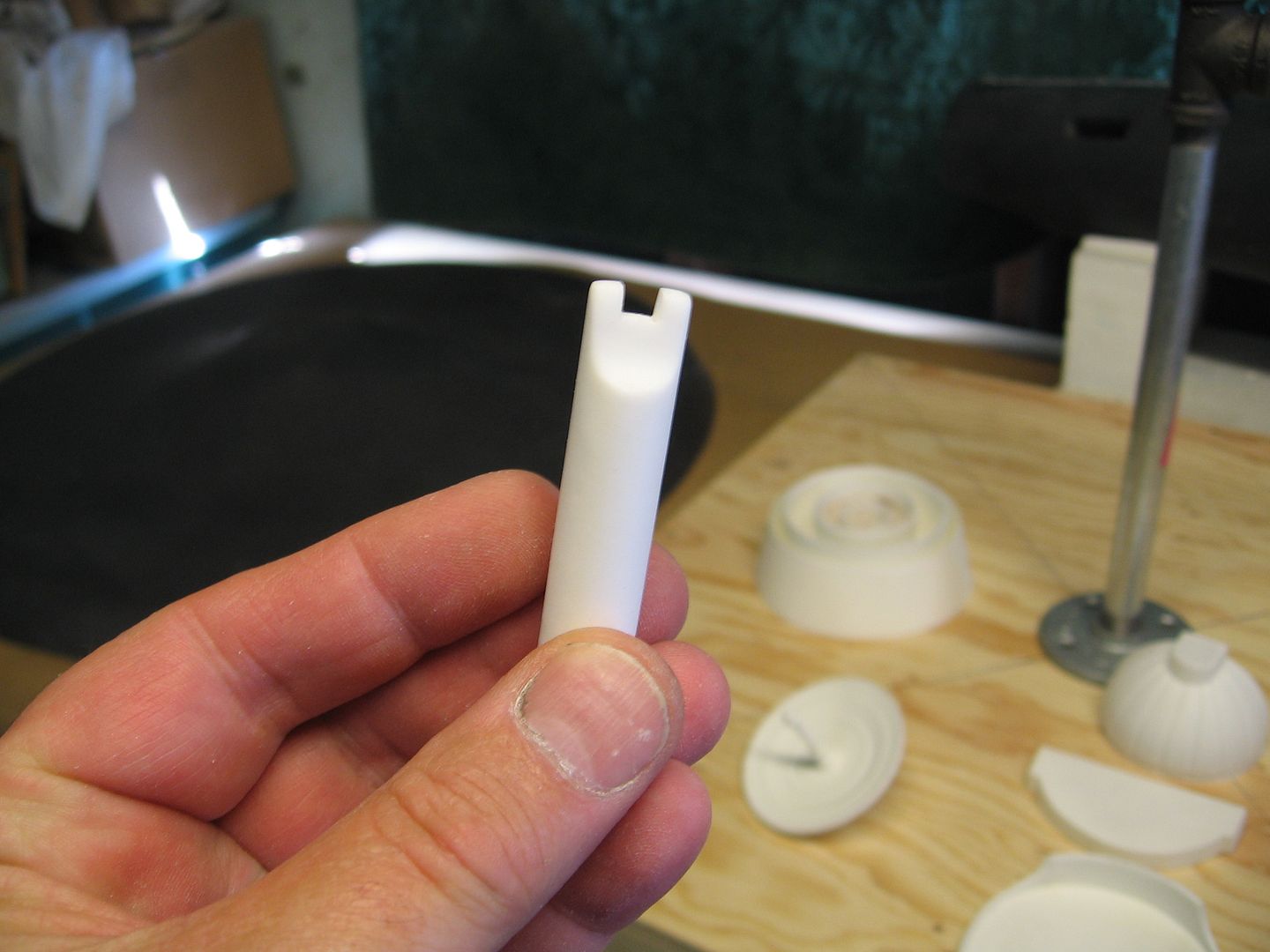

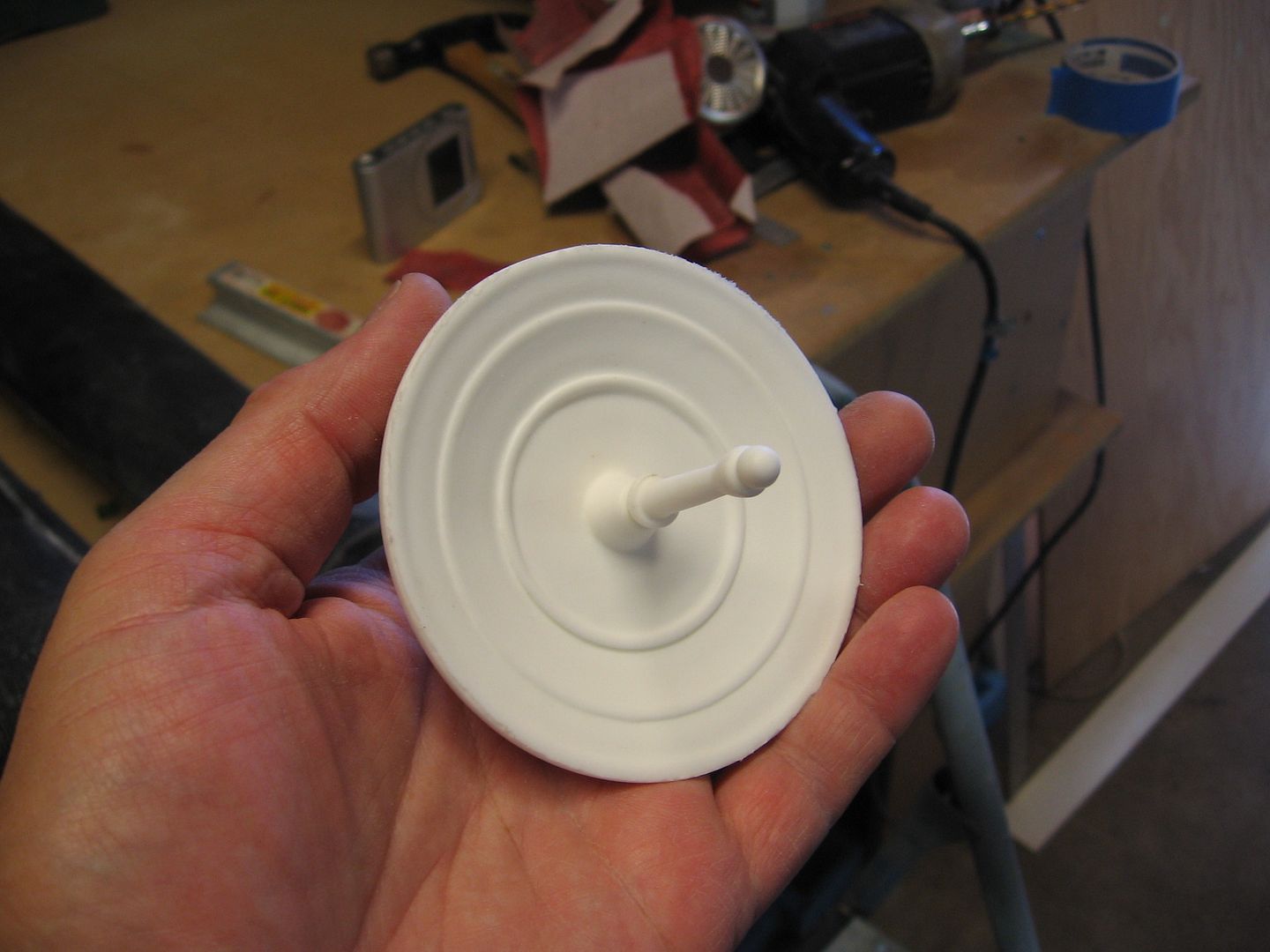

Here's some pictures of todays little project. There will be lots more tomorrow and video.

Steve

Yes the Enterprise's vinyl decals. Lou you rock! These are the biggest decals I have ever worked with. The package was marked don't bend but they did it anyway. Seems to me they are the dummies but all is well.

Here's some pictures of todays little project. There will be lots more tomorrow and video.

Steve