SteveNeill

Sr Member

My pressure pot is on the fritz so I have a problem there. I'll try the baling soda though, thanks for all the input on that guys.

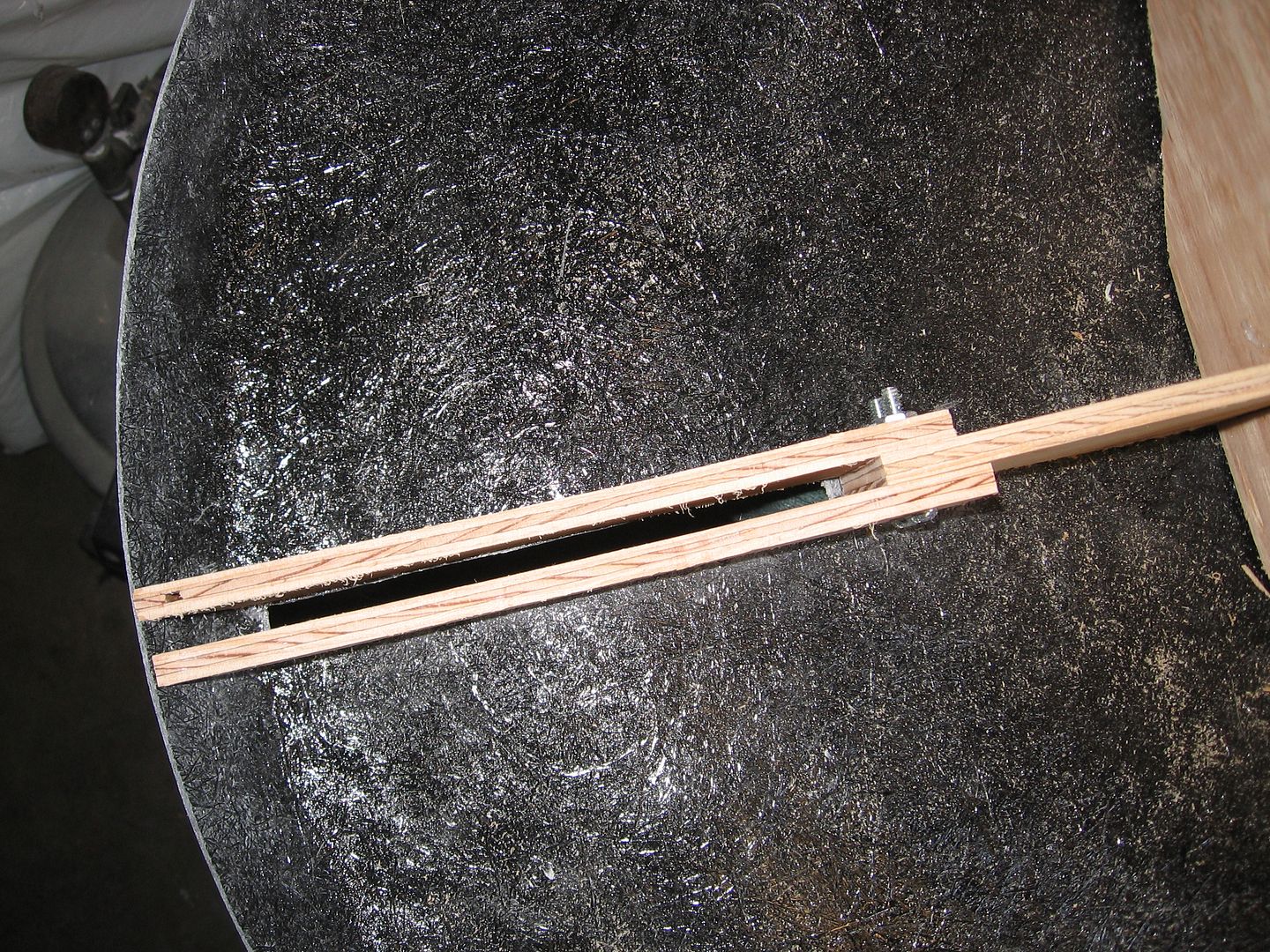

the plywood is 1/4 inch.

And yes on mine anyway I will light the impulse engines. That will be the only non original TOS change. I'm even going to black out the same windows.

Thanks all I'm going to try and tape together and assemble much of the ship for a look today. A few more parts to pour too. I'm leave the transparent stuff to the end. It's not really clear on the real deal anymore than the windows are.

Steve

the plywood is 1/4 inch.

And yes on mine anyway I will light the impulse engines. That will be the only non original TOS change. I'm even going to black out the same windows.

Thanks all I'm going to try and tape together and assemble much of the ship for a look today. A few more parts to pour too. I'm leave the transparent stuff to the end. It's not really clear on the real deal anymore than the windows are.

Steve