xl97

Master Member

Re: Spiderman web shooter: A collaborative project. Now with wiring diagrams!

I can do it on my work computer..

(stinks for tonight though.. was ready to put in a few hours) lol

(I suppose I can watch Walking Dead though now)

Good for 20 saves?..so if I never save anything.. Im ok to open things forever? haha..

I dont know the first thing about it..(hope I dont get overwhelmed with all the interface/GUI controls?)

easy to grab a model/file and get dimensions? and move it around?

other things to note.. I just checked out..

we can get read or blue PCB's for only $5.00 more bucks..

and 0.0393701 " thick PCBs for same price..

(thickness)

.8mm - $2.00 more

.6mm - $10.00 more

.4mm - $25.00 more

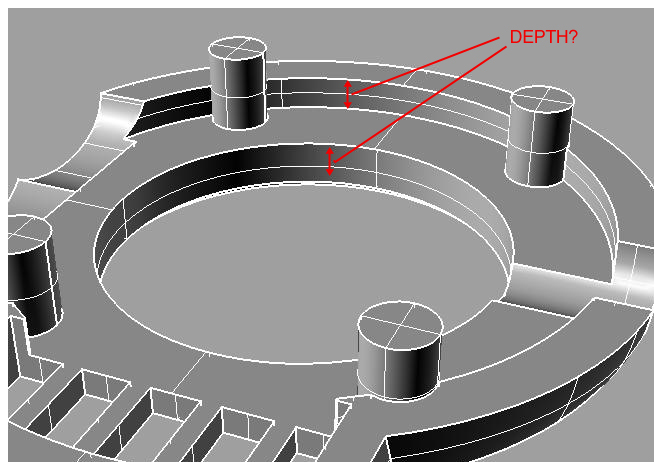

using a thinned pcb may help since we have limited room.. (especially depth)

(this is also for a 'batch' of 9-10 pcbs though too)

I think red would be good for this project..

can do 'real' time web shooter.. fwwwip sound.. and take away from the led bargraph after xx amount of presses..

have to reload.....

random quotes from the movie..

damn... (I totally forgot about a speaker!!!!!!)

grrr.. (too excited about this project, need to slow down I guess) lol

edit:

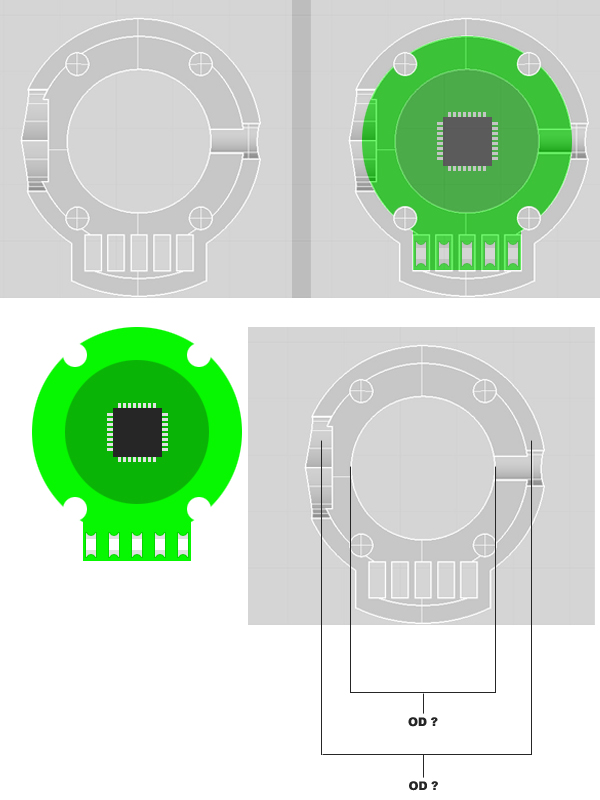

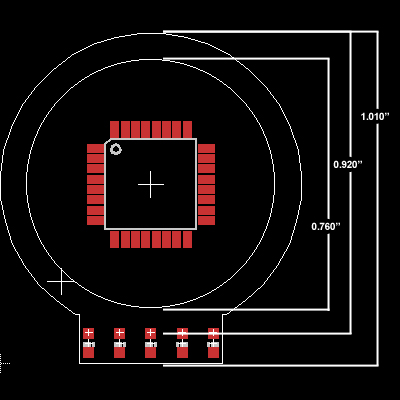

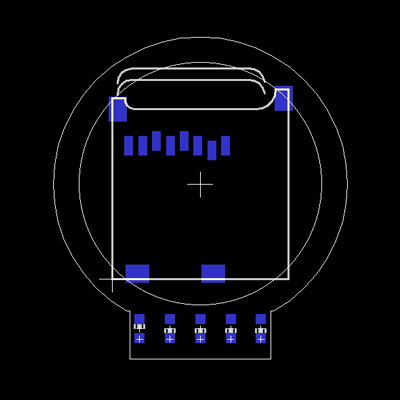

I just added the micro SD socket footprint to the layout.. and Im pretty confident now that there will be NO SOUND for these on the stock/default/current models..

the micro SD socket is pretty big compared to the inner circle (bingo chip hole Im calling it)..

(.75 in ID..until Im told different)..

as it will bump into the legs/posts on the bezel piece

**** maybe if I can rotate it a bit to fit inside of the posts?

a no sound version is 100% possible I think..

I can do it on my work computer..

(stinks for tonight though.. was ready to put in a few hours) lol

(I suppose I can watch Walking Dead though now)

Good for 20 saves?..so if I never save anything.. Im ok to open things forever? haha..

I dont know the first thing about it..(hope I dont get overwhelmed with all the interface/GUI controls?)

easy to grab a model/file and get dimensions? and move it around?

other things to note.. I just checked out..

we can get read or blue PCB's for only $5.00 more bucks..

and 0.0393701 " thick PCBs for same price..

(thickness)

.8mm - $2.00 more

.6mm - $10.00 more

.4mm - $25.00 more

using a thinned pcb may help since we have limited room.. (especially depth)

(this is also for a 'batch' of 9-10 pcbs though too)

I think red would be good for this project..

can do 'real' time web shooter.. fwwwip sound.. and take away from the led bargraph after xx amount of presses..

have to reload.....

random quotes from the movie..

damn... (I totally forgot about a speaker!!!!!!)

grrr.. (too excited about this project, need to slow down I guess) lol

edit:

I just added the micro SD socket footprint to the layout.. and Im pretty confident now that there will be NO SOUND for these on the stock/default/current models..

the micro SD socket is pretty big compared to the inner circle (bingo chip hole Im calling it)..

(.75 in ID..until Im told different)..

as it will bump into the legs/posts on the bezel piece

**** maybe if I can rotate it a bit to fit inside of the posts?

a no sound version is 100% possible I think..

Last edited: