MTB

Sr Member

I wanted to share my progress on my Veepy build

(Thread here: https://www.therpf.com/forums/threads/rocketeer-“veepy”-jetpack-3d-printable-kit-project.331821/)

gnolivos did such a fantastic job on this and all for the community (he is making zero profit from this)! This is hands down the most accurate 3d printable X3 out there!

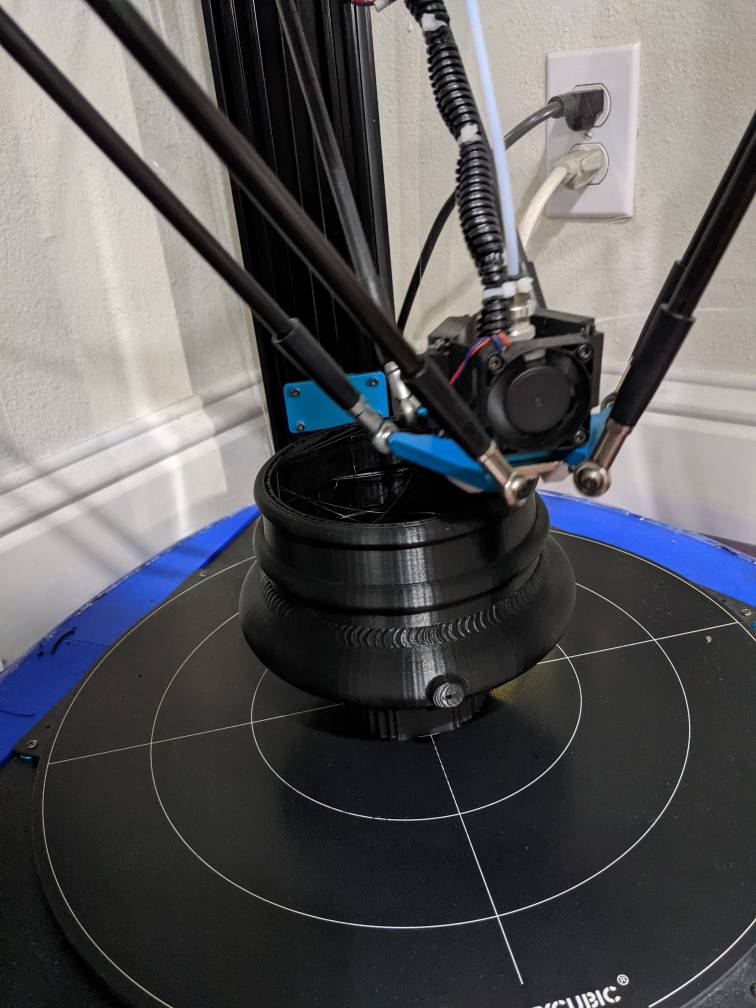

I have printed all but the upper engine and the right engine flap. I have the lower engine printing now and it should be done in about an hour and a half.

I printed everything on my Anycubic Predator printer. It will end up taking just over 3 rolls of filament. I like to use minimal supports, as you can see from the engine pic, so your results may very. I'm slicing with simplified 3D so I can place the supports where I want them.

I have started the best part of any 3d print....sanding! I tried to sand parts as others were printing to save time but kinda fell off it. I have decided on the colors yet but I will be airbrushing the whole thing. I don't think I'll add the electronics but I will be adding the fan and having it operational.

I will continue to update and as more progress is made.

(Thread here: https://www.therpf.com/forums/threads/rocketeer-“veepy”-jetpack-3d-printable-kit-project.331821/)

gnolivos did such a fantastic job on this and all for the community (he is making zero profit from this)! This is hands down the most accurate 3d printable X3 out there!

I have printed all but the upper engine and the right engine flap. I have the lower engine printing now and it should be done in about an hour and a half.

I printed everything on my Anycubic Predator printer. It will end up taking just over 3 rolls of filament. I like to use minimal supports, as you can see from the engine pic, so your results may very. I'm slicing with simplified 3D so I can place the supports where I want them.

I have started the best part of any 3d print....sanding! I tried to sand parts as others were printing to save time but kinda fell off it. I have decided on the colors yet but I will be airbrushing the whole thing. I don't think I'll add the electronics but I will be adding the fan and having it operational.

I will continue to update and as more progress is made.