Loess

Member

For the last year or so, I've been working on combining my job as a CAD worker, my engineering degree, and some gunsmithing experience to do something very awesome.

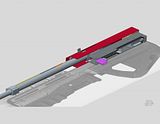

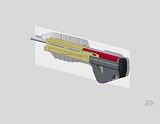

I'm going to build a real-steel, live firing MA5C.

I have been staying at the office after hours, and spending lunch breaks at my desk, and I finally have some models far enough along that it's time to share some screen shots with the folks here.

About a year ago, I was reading about old, unusual rifles, and ran across a video of the internal components of the German FG42 Paratrooper rifle. Seeing how short the action in it is, I started thinking about using it to make a functional MA5. After somewhere north of 500 hours of design time, I've gone away from the FG42 operating system, to my own custom derivation of a Leader Dynamics T2 rifle.

I've given up on fitting the 7.62x51 NATO cartridge into the rifle that the fiction specifies, since it's just too big to work. (That's where most of the 500 hours went.)

Instead, I'll be chambering it for 5.56x45, since I already have rifles and the reloading equipment for it.

I'm currently looking at building a custom reciever around a stock AR15 barrel and barrel extension, with a custom bolt carrier and a modified AR15 bolt.

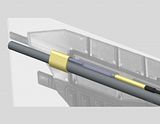

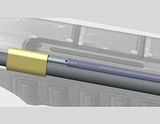

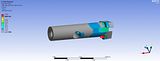

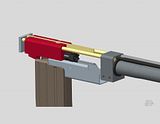

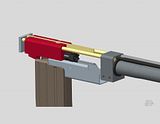

Here's a view of the gas piston, if you watched the Leader video, you should recognize how it works.

The piston and charging handle go through the trunnion block, and push on the bolt carrier. The piston will push the carrier for 0.75 inches, which puts enough energy into it to completely cycle the rifle. The charging handle also goes through the trunnion, but it will run back through the entire travel length of the bolt.

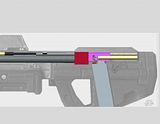

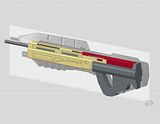

The bolt and carrier lock in place much the same way that a standard AR bolt does.

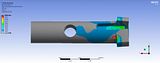

These screen shots also show the extended feed ramp.

Since the rifle is so short behind the magazine well, I had to figure out a way for the bolt carrier to pick up a round from the mag, and pull it forward into the feed ramp, then on the next cycle, the bolt will pick up and load the round in the feed ramp as it is grabbing the next round out of the magazine.

This will do for getting ammo into the chamber, but it's going to be more susceptible to feed stoppages.

This design has the advantages of using off-the shelf parts for the barrel extension and bolt, since they have to be cut from tool steel and hardened fairly precisely. It also will use standard GI magazines, to remove some complexity there. I'm still kicking around the idea of machining the locking lugs and barrel mounting threads directly into the trunnion, since that would eliminate any chance of the barrel extension working itself loose from the trunnion.

I don't know exactly how soon I'll be cutting metal, since I want to have the models fully complete and detailed, and the drawings made before I begin ordering parts.

I suppose I should add that Yes, this is legal where I live. It will be semi-auto only, to stay that way.

I'm going to build a real-steel, live firing MA5C.

I have been staying at the office after hours, and spending lunch breaks at my desk, and I finally have some models far enough along that it's time to share some screen shots with the folks here.

About a year ago, I was reading about old, unusual rifles, and ran across a video of the internal components of the German FG42 Paratrooper rifle. Seeing how short the action in it is, I started thinking about using it to make a functional MA5. After somewhere north of 500 hours of design time, I've gone away from the FG42 operating system, to my own custom derivation of a Leader Dynamics T2 rifle.

I've given up on fitting the 7.62x51 NATO cartridge into the rifle that the fiction specifies, since it's just too big to work. (That's where most of the 500 hours went.)

Instead, I'll be chambering it for 5.56x45, since I already have rifles and the reloading equipment for it.

I'm currently looking at building a custom reciever around a stock AR15 barrel and barrel extension, with a custom bolt carrier and a modified AR15 bolt.

Here's a view of the gas piston, if you watched the Leader video, you should recognize how it works.

The piston and charging handle go through the trunnion block, and push on the bolt carrier. The piston will push the carrier for 0.75 inches, which puts enough energy into it to completely cycle the rifle. The charging handle also goes through the trunnion, but it will run back through the entire travel length of the bolt.

The bolt and carrier lock in place much the same way that a standard AR bolt does.

These screen shots also show the extended feed ramp.

Since the rifle is so short behind the magazine well, I had to figure out a way for the bolt carrier to pick up a round from the mag, and pull it forward into the feed ramp, then on the next cycle, the bolt will pick up and load the round in the feed ramp as it is grabbing the next round out of the magazine.

This will do for getting ammo into the chamber, but it's going to be more susceptible to feed stoppages.

This design has the advantages of using off-the shelf parts for the barrel extension and bolt, since they have to be cut from tool steel and hardened fairly precisely. It also will use standard GI magazines, to remove some complexity there. I'm still kicking around the idea of machining the locking lugs and barrel mounting threads directly into the trunnion, since that would eliminate any chance of the barrel extension working itself loose from the trunnion.

I don't know exactly how soon I'll be cutting metal, since I want to have the models fully complete and detailed, and the drawings made before I begin ordering parts.

I suppose I should add that Yes, this is legal where I live. It will be semi-auto only, to stay that way.