Took a pass at polishing the metal parts. Most of the polishing was done with a big 8 inch muslin buffing wheel mounted to a motor spinning at 1725 rpm.

I also used several small muslin and felt buffing bits on a Foredom Flex shaft.

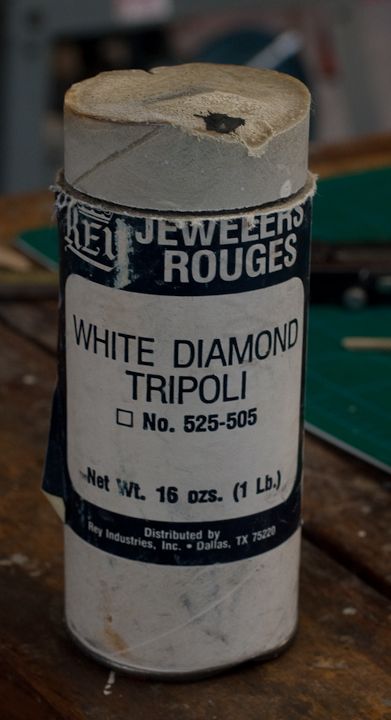

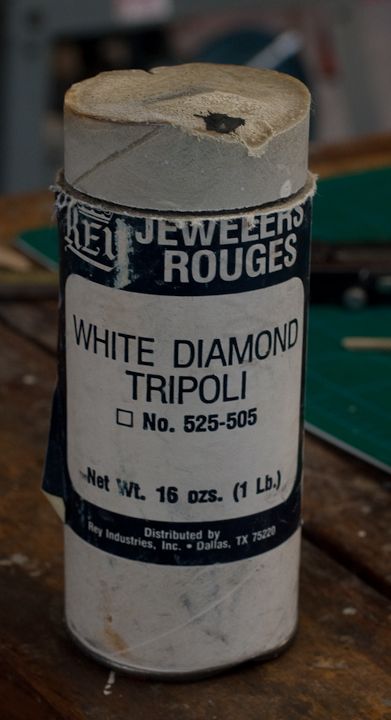

I used White Diamond Tripoli dry polishing compound. It comes in stick and block form and you charge the spinning wheel with a bit of the compound and then hold the metal piece to it. There is actually no diamond dust in White Diamond. There are quite a few different polishing compounds available, dry and wet. White Diamond is frequently used for plashing white metals like silver and nickel, so it seemed like a good choice here.

These materials and buffing wheels are widely available from jewelers supply sources. You could use the small wheels and tips in a Dremel, just be careful, as I've warned before, Dremels spin way fast and can burn through plated surfaces if you are not careful.

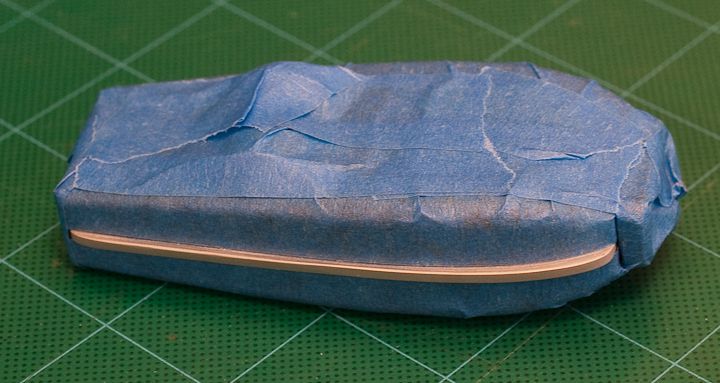

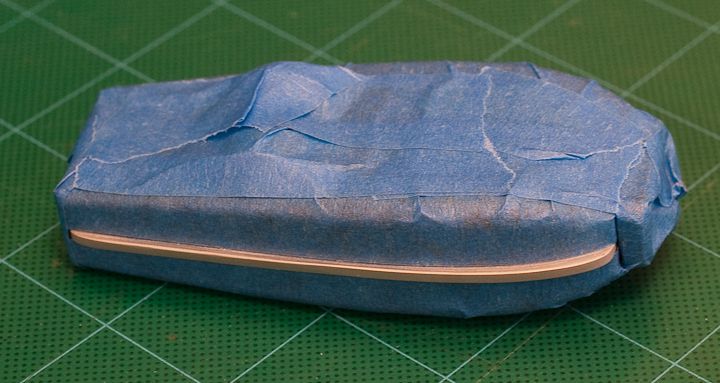

Before polishing I masked off the plastic phaser body with blue painters tape.

And here are the results, before and after. It didn't take too much effort. The results are actually much more visible to the eye than the camera.

And the crystal compartment cover. Since it could be removed it was easier to be a little more aggressive with the polishing. I used the smaller felt wheel and tip a lot on this piece. I also tried on the back area to bear down and burn through to the copper sub plating. but the top plating held up really well.

I particularly like how the polished cover looks in contrast with the matte finish of the surrounding ring!

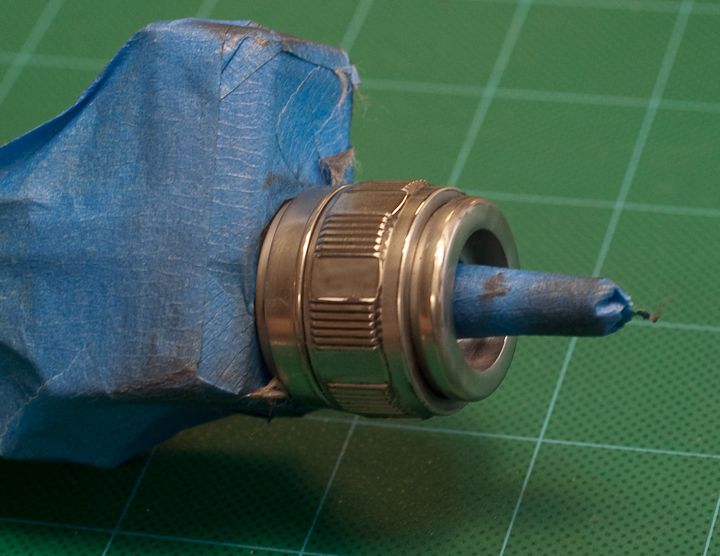

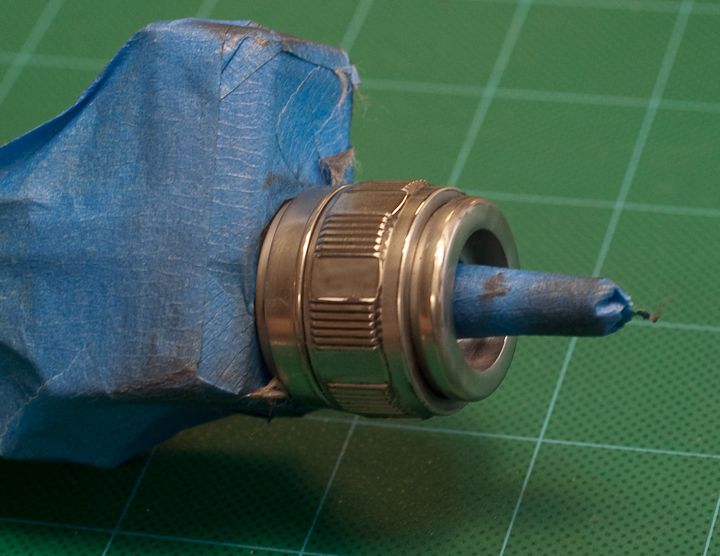

Masked off the P2 emitter and polished it up, first with the big wheel, then with the smaller tools to get around the edges.

WARNING! the bent metal plate on top of the P2 is treated differently than the other cast and plated parts. It might even be painted. The buffing wheel left grey marks on the surface instead of polishing it. I ran out of time to investigate further.

I also did not get to polishing the fins on the back of the P2. Will try to get to that tomorrow.

As I said earlier, you can probably get good results with a Dremel if you are careful. Also there are smaller 3 and 4 inch muslin buffing wheels and arbors that you can use with a drill motor clamped down to your workbench. I happen to have a big polisher for doing silversmithing, but it's not required. The trick when polishing metals not to try to get every surface polished. The contrast of dull recessed surfaces to highly polished outer edges looks better and more realistic. I saw the pre production version of this phaser at Comic Con last summer when all the metal plated surfaces were bright and shiny. Looked a little cheap. I'm glad the Wand Co. went with the satin finished plating. Now we can polish or not to taste.

Be sure to wear eye protection and watch your fingers, though generally speaking the spinning wheel might only give you a bit of a burn. Gloves are usually not recommended as they can get caught in the wheel.