Monkey540

Sr Member

Hello again,

I have been wanting to make a full quidditch trunk for some time.

I have noticed from other builds there was minimal details on actually building the box, and I wanted to give a full process as I see a lot of questions about this, as well as some things I've figured out on my own. I hope it helps anyone working on their own.

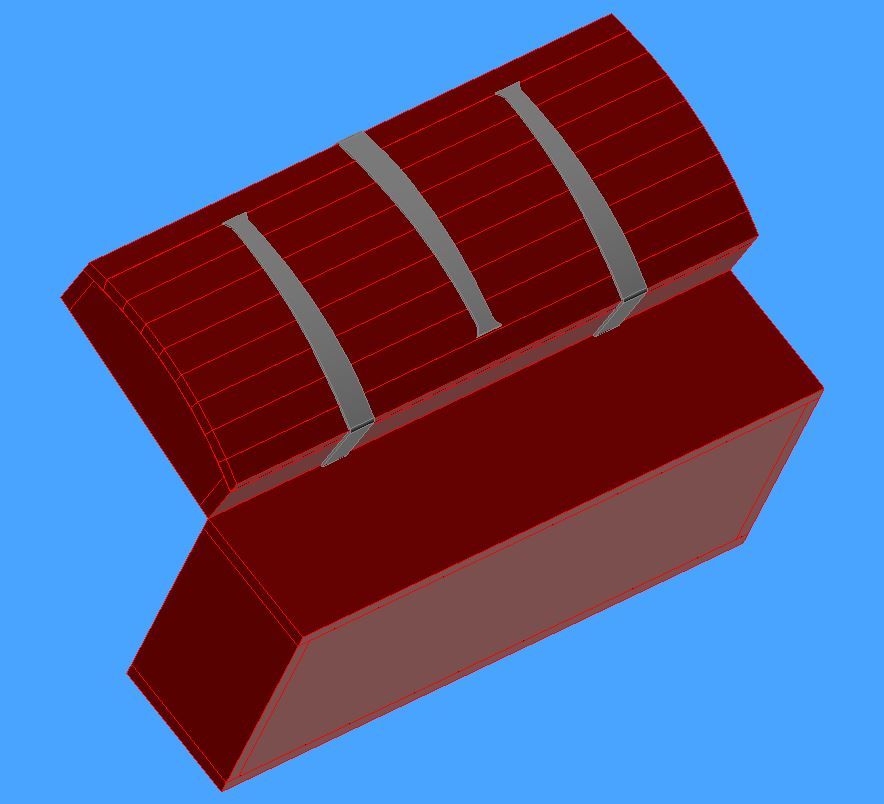

Here's a look at the completed trunk:

Here's the full story

A few years ago I started by making my own beater bats, see the build here:

www.therpf.com

www.therpf.com

But then I didn't continue. Finally, last year, I entered my golden snitch in a prop replica contest here in Edmonton, and I won best Novice Maker (never won an award category)

That build thread can be found here:

www.therpf.com

www.therpf.com

This has motivated me to revisit this project and see it through to enter in this years competition.

This will be my build from (almost) scratch.

I started as I usually do, but 3D modelling the project to try and get some rough bearings on how I'm going to do this and came up with this design sized from the Universal Studios Quaffle that I own.

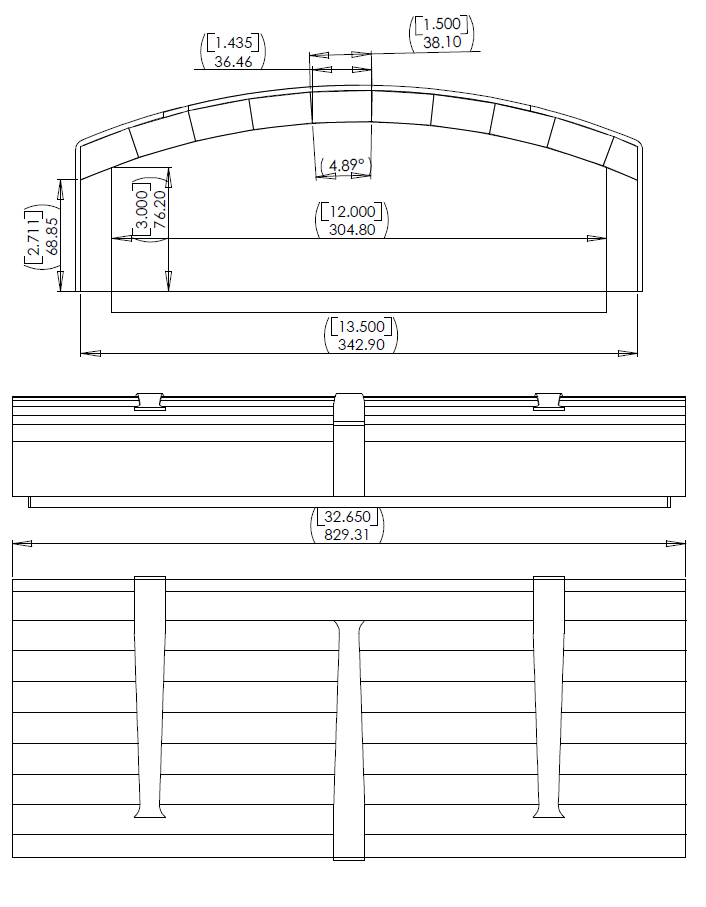

This is designed to have a thickness of 1" lumber so I can utilize 1" x ? whitewood to build it.

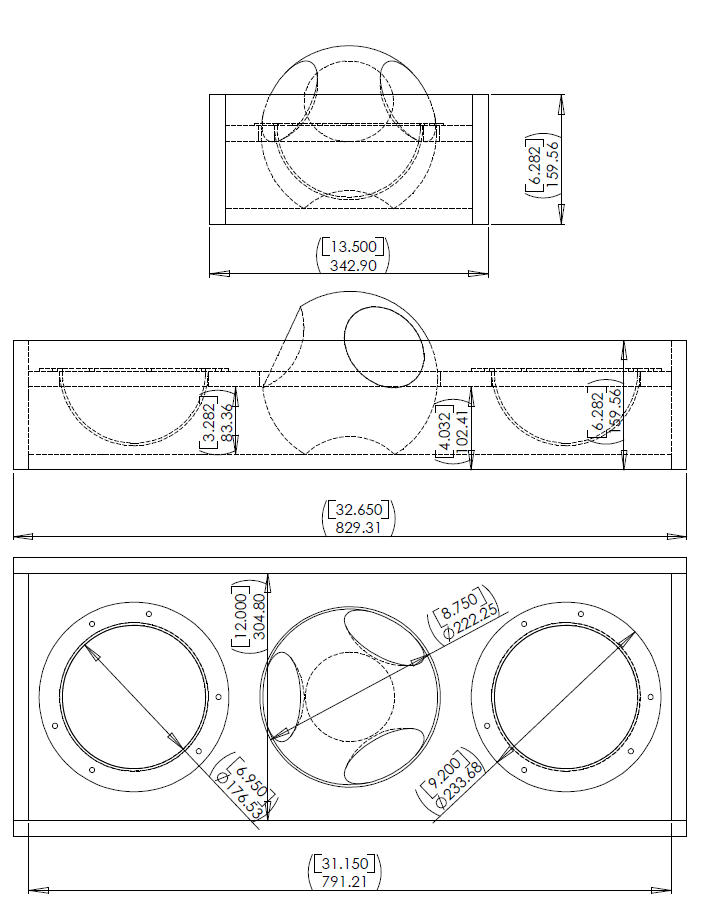

To go along with this design, I generated a technical drawing to start ordering my material.

This project will involve a lot of firsts for me, but I think I'm much more prepared now than I was 5 years ago.

I have been wanting to make a full quidditch trunk for some time.

I have noticed from other builds there was minimal details on actually building the box, and I wanted to give a full process as I see a lot of questions about this, as well as some things I've figured out on my own. I hope it helps anyone working on their own.

Here's a look at the completed trunk:

Here's the full story

A few years ago I started by making my own beater bats, see the build here:

Harry Potter Quidditch Beater's Bat Replica

Hey everyone, I just started a new build and I'm really quite excited about how it's turning out. I managed to work out a design for the beater's bat with some help from friends, and rather than fully 3D print it, I decided I'd try to make it a wooden bat. Naturally, I started with a 3D model...

But then I didn't continue. Finally, last year, I entered my golden snitch in a prop replica contest here in Edmonton, and I won best Novice Maker (never won an award category)

That build thread can be found here:

Harry Potter - Golden Snitch - DH version, Opening snitch modelling

Hey there everyone. I was keeping this project to myself, but thought I might be able to get some good input on it if I share it with everyone, so here we go. It's been a dream of mine to have a working opening replica of the golden snitch such as the one seen in DH. As seen in the photo...

This has motivated me to revisit this project and see it through to enter in this years competition.

This will be my build from (almost) scratch.

I started as I usually do, but 3D modelling the project to try and get some rough bearings on how I'm going to do this and came up with this design sized from the Universal Studios Quaffle that I own.

This is designed to have a thickness of 1" lumber so I can utilize 1" x ? whitewood to build it.

To go along with this design, I generated a technical drawing to start ordering my material.

This project will involve a lot of firsts for me, but I think I'm much more prepared now than I was 5 years ago.

Attachments

Last edited: