You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Adventures in 3D Printing

- Thread starter masterjedi322

- Start date

TazMan2000

Master Member

Your extruder seems to be feeding more filament than it needs. You might need to tune your system.

Retraction settings might need to be modified as well. If your hot end is too hot, this could happen as well.

TazMan2000

Retraction settings might need to be modified as well. If your hot end is too hot, this could happen as well.

TazMan2000

Last edited:

xeno

Sr Member

Anybody know what’s causing the fuzzy strands sticking out on the print?View attachment 1455611

material flow too much, is it 100% and could go 99%, but you run the risk of underextrusion.

temperature too high, colder can maybe result in less layer adhesion and breakable part.

Retraction not enough, check if your bowden-tube is not moving during retraction.

if they are easy removable, I tend to leave the settings alone to have a strong part

Temp could be high - Im running at 200 in a florida garage on the extruder

I'll check retraction.

It does flake off pretty easily so I may not monkey with it too much. Almost half way through a pit-droid for my wife.

On another note - What adhesive should I use for PLA?

I'll check retraction.

It does flake off pretty easily so I may not monkey with it too much. Almost half way through a pit-droid for my wife.

On another note - What adhesive should I use for PLA?

TazMan2000

Master Member

I wouldn't go lower than 200 degrees. I don't see a problem with your print, except for blobs mostly on your supports. There are several videos on YouTube that show you how to tune your printer if you need. Use CA glue for PLA. Sanded parts are almost impossible to take apart without wrecking one or both parts, so ensure that you are precise with your placement. I use locator pins made of brass. Most times I design my parts with corresponding holes, but with models that I have downloaded, I drill holes to accommodate them. Test fit several times and glue once.Temp could be high - Im running at 200 in a florida garage on the extruder

I'll check retraction.

It does flake off pretty easily so I may not monkey with it too much. Almost half way through a pit-droid for my wife.

On another note - What adhesive should I use for PLA?

TazMan2000

I’m sorry to hear about the troubles you‘ve been having...I've recently picked up the photon mono, and the wash and cure 2.0 and I promptly punctured the fep trying to remove cured resin from it when the little spatula broke very easily and cleaved the plastic open. After swearing like I had tourettes for about 2 hours (I have a habit of breaking things right after I get them) I ordered replacement frame/feps from anycubic (because the frame holding the sheet is glued together), which I've heard can take months to actually arrive, so I hit reddit to see what the "experts" are recommending. I then ordered an aluminum vat with an already installed fep. My first test print was pretty good, not perfect. Did the cube. It's wonky here and there. I was happy with it enough to set up some Silverhand grips (which is the reason I decided to finally get into resin printing) and YEAH, weeks have gone by now and I don't have a single successful print other than that first cube. I have some 3in1 PTFE lube on order, that is my next step to try and get a decent print done...

As I’m learning more about the AnyCubic, I genuinely believe they are good machines. I would encourage you to check out the exposure test video posted earlier in this thread and get your resin settings dialed in - that was a huge turning point for me. The PTFE lubricant was also a big help.

Happy to chat more if there‘s any assistance I can offer!

Sean

Noeland

Master Member

I will do that. And I am always up for chatting about 3D printing and props! That sounds great. I will be in touch. Thank you.I’m sorry to hear about the troubles you‘ve been having...

As I’m learning more about the AnyCubic, I genuinely believe they are good machines. I would encourage you to check out the exposure test video posted earlier in this thread and get your resin settings dialed in - that was a huge turning point for me. The PTFE lubricant was also a big help.

Happy to chat more if there‘s any assistance I can offer!

Sean

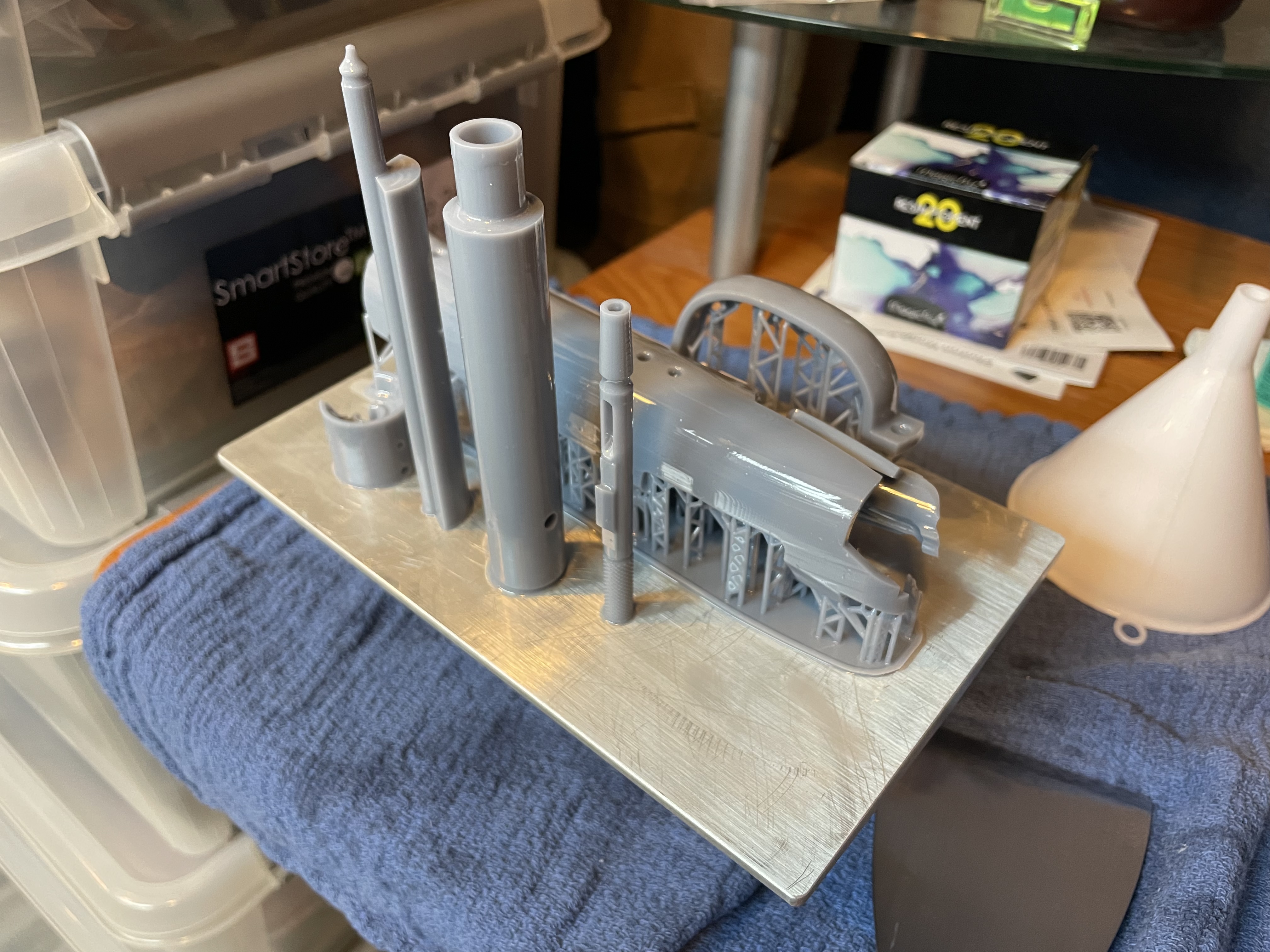

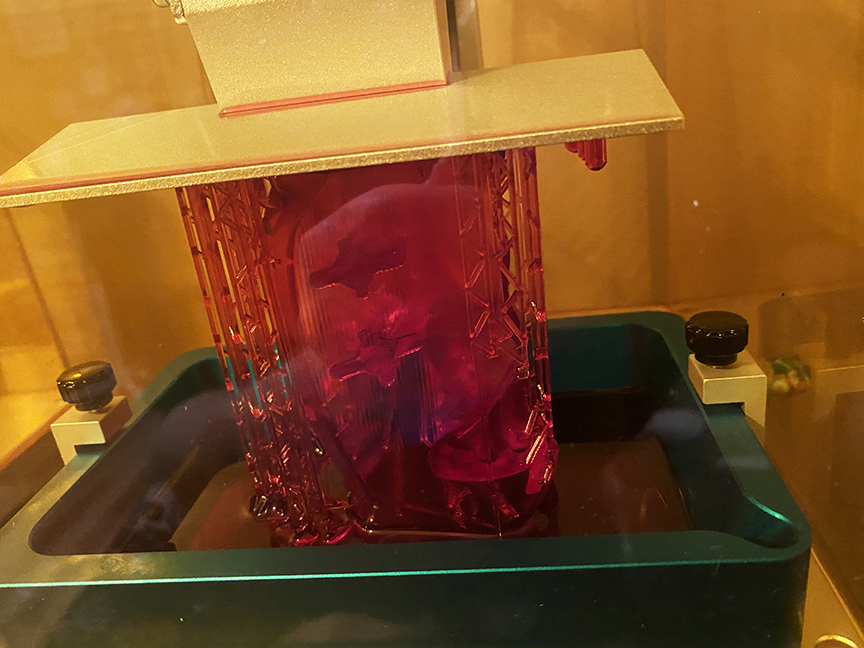

Following up on my earlier post involving a 12-hour print - overall, things came out very well!

I was especially impressed that the tall long pieces adhered to the build plate and held on for the entire build! More so, the print finished in the middle of the night, and the parts all hung there for ~6 hours after the print had finished!

The only problem was the back end of the Steyr receiver got mucked up. Will need to reprint that…

Sean

I was especially impressed that the tall long pieces adhered to the build plate and held on for the entire build! More so, the print finished in the middle of the night, and the parts all hung there for ~6 hours after the print had finished!

The only problem was the back end of the Steyr receiver got mucked up. Will need to reprint that…

Sean

Reprinted the Steyr receiver on its own. Bumped up the supports.

Sean

Sean

now you need 1 more printer so you can be twice as fast...but if you had 4 more you could save so much time.

I like how you think!now you need 1 more printer so you can be twice as fast...but if you had 4 more you could save so much time.

As I‘ve been sitting back watching this thing go, I started thinking:

- I need more printers

- I need bigger printers

I have a big project coming up that I intend on tackling with this one. We’ll see whether that’s enough to push me to add more to the arsenal...

Sean

Noeland

Master Member

Well, watched a whole bunch of videos, changed some settings, and tinkered around with chitubox to make STL's with supports already included, sliced through photon workshop. Exact same results as above. I'm going to replace the fep today and see if that changes anything. I'm not expecting it to, but I just have to keep trying different things. The validation matrix did not help when it does not print.

I haven't even tested my IBEE yet and I want 3 more.I like how you think!

As I‘ve been sitting back watching this thing go, I started thinking:

While I am still very much cutting my teeth on all of this, I can definitely see the advantages of having multiple printers of varying sizes.

- I need more printers

- I need bigger printers

I have a big project coming up that I intend on tackling with this one. We’ll see whether that’s enough to push me to add more to the arsenal...

Sean

ID10T

Sr Member

Well, I was out bid on an open box unit last night, so I’m getting closer. (Winner paid new unit price which was my upper threshold).

And I have a half-liter of resin on the way. So, I guess that makes it official. I plan to huff the resin when it arrives to get an idea how stinky it is.

Oh, look! A rabbit hole!

And I have a half-liter of resin on the way. So, I guess that makes it official. I plan to huff the resin when it arrives to get an idea how stinky it is.

Oh, look! A rabbit hole!

Sorry if I missed it, but which printer did you decide on?Well, I was out bid on an open box unit last night, so I’m getting closer. (Winner paid new unit price which was my upper threshold).

And I have a half-liter of resin on the way. So, I guess that makes it official. I plan to huff the resin when it arrives to get an idea how stinky it is.

Oh, look! A rabbit hole!

Meanwhile, I’m still chipping away on the Blade Runner blaster parts. Almost done!

I have a bottle of clear resin and some dye, so I might try to print the grips using that.

Sean

When I was researching printers, I got stuck between the AnyCubic Photon Mono X and the Peopoly Phenom L. I really wanted the Phenom just because of its huge print volume (being able to print whole helmets and armor pieces sounded great!), but I couldn’t justify the 3x price compared to the Mono X, especially for my first printer.I haven't even tested my IBEE yet and I want 3 more.

Might make for a nice upgrade in the future…

Sean

Noeland

Master Member

OK, so the secret to a successful print with the Photon Mono is apparently the Lychee slicer. I did a deep dive into the photon on youtube and reddit and discovered the Lychee slicer.

Boom!

Not only does Lychee let you choose the printer, but you can tell it which brand, type, and color of resin you are using. I have been using chitubox and photon workshop, but found out that chitubox and anycubic don't really get along well. So that may have been the issue I was having, not sure. These grips are still printing, but I will post up whatever results I get.

In the mean time, if you're using Anycubic and having issues like I was, download the Lychee slicer!!

Boom!

Not only does Lychee let you choose the printer, but you can tell it which brand, type, and color of resin you are using. I have been using chitubox and photon workshop, but found out that chitubox and anycubic don't really get along well. So that may have been the issue I was having, not sure. These grips are still printing, but I will post up whatever results I get.

In the mean time, if you're using Anycubic and having issues like I was, download the Lychee slicer!!

That's great! I was racking my brain as to what could be causing your issues, but I hadn't thought about the slicer!

As I was researching printers, I downloaded Chitubox to start learning it. I soon found Lychee and instantly preferred it over Chitubox.

Pretty sure both slicers let you select a printer and resin settings, but I found Lychee just worked better for me (although I know a lot of folks have had success with Chitubox).

So glad you got it figured out!

I seem to be having a new issue...I'm printing a helmet that's broken into pieces to fit onto the build plate. However, some of the corners are coming out soft (see picture). I should note this is the same edge where the supports were, so similar to my earlier issue.

Any thoughts on what's causing this or how to fix it?

Sean

As I was researching printers, I downloaded Chitubox to start learning it. I soon found Lychee and instantly preferred it over Chitubox.

Pretty sure both slicers let you select a printer and resin settings, but I found Lychee just worked better for me (although I know a lot of folks have had success with Chitubox).

So glad you got it figured out!

I seem to be having a new issue...I'm printing a helmet that's broken into pieces to fit onto the build plate. However, some of the corners are coming out soft (see picture). I should note this is the same edge where the supports were, so similar to my earlier issue.

Any thoughts on what's causing this or how to fix it?

Sean

ID10T

Sr Member

Sorry if I missed it, but which printer did you decide on?

...

Sean

I think the Elegoo Mars 2 (non-pro version) is the right one for me. The 2 pro adds the metal resin vat, 10mm additional print height and an exhaust fan that adds additional smell to the workspace. Plus green is my favorite color, so at the end of the day that's really all that matters... The only real "upgrade" of the pro is that extra 10mm of height. And, due to popularity I guess, the Pro can be had for less than the regular 2 on the street.

I was bidding on the pro, figuring I'd disable the fan once I got it, but I didn't get it.

So, I'm back on the hunt. But I'm spending money on my Rostock costume faster than the US Government, so I'm either ordering my jacket from Magnoli, or getting a printer. Maybe both if I do the 50-50 payment option with Magnoli, since the delivery time is roughly two months.

Because I also want to get the wash n cure gizmo as well (did I mention the rabbit hole?), just to be sure my prints are properly washed and cured. Mainly washing, since I can put it in a spray booth here with the plasma gun and bombard it with enough UVB in a minute as it'd get being in the bright sun for an hour.

Other goodies on my list include a pair of spare vats, and dust covers because it's really dusty here. I don't think I need anything else. Skill and experience would be nice I suposse.

Similar threads

- Replies

- 1

- Views

- 251

- Replies

- 2

- Views

- 306