You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Adventures in 3D Printing

- Thread starter masterjedi322

- Start date

AmazinSpiderboy

New Member

Hi al!,

Just finished reading up all the previous posts, and I figured I'd reach out in this forum since it dedicate to getting better at prop making using 3d printers. So I currently have a Longer Pro 3D printer, slicing with Simplify3D and i've been using PLA filament for most of my projects. I've currently been building a Naruto Ninja Scroll to hold some documents within it. The total build is gonna be a little bit over 3ft tall, hence I've been printing in components little by little. Originally I was relying on using a joint based system to connect it all and double down on its adhesiveness with super glue. But I'm starting to notice that the super glue isn't that strong of an adhesive for the object to maintain its connectivity as well as hold weight within in down the line.

So I was wondering if anyone has any solutions to how I can create a more adhesive unit that can hold weight? because my only idea as of now is to use car putty or body filler like how people used for pepakura based projects.

Any help would be greatly appreciated, down below are some attachments of what I currently have so far and the scroll i'm aiming to model it after !!

Just finished reading up all the previous posts, and I figured I'd reach out in this forum since it dedicate to getting better at prop making using 3d printers. So I currently have a Longer Pro 3D printer, slicing with Simplify3D and i've been using PLA filament for most of my projects. I've currently been building a Naruto Ninja Scroll to hold some documents within it. The total build is gonna be a little bit over 3ft tall, hence I've been printing in components little by little. Originally I was relying on using a joint based system to connect it all and double down on its adhesiveness with super glue. But I'm starting to notice that the super glue isn't that strong of an adhesive for the object to maintain its connectivity as well as hold weight within in down the line.

So I was wondering if anyone has any solutions to how I can create a more adhesive unit that can hold weight? because my only idea as of now is to use car putty or body filler like how people used for pepakura based projects.

Any help would be greatly appreciated, down below are some attachments of what I currently have so far and the scroll i'm aiming to model it after !!

Attachments

Evening Newbs

New Member

I'm a fan of Gorilla Glue Clear for PLA. It's much less brittle than CA, and it doesn't foam up like their regular formula.Hi al!,

Just finished reading up all the previous posts, and I figured I'd reach out in this forum since it dedicate to getting better at prop making using 3d printers. So I currently have a Longer Pro 3D printer, slicing with Simplify3D and i've been using PLA filament for most of my projects. I've currently been building a Naruto Ninja Scroll to hold some documents within it. The total build is gonna be a little bit over 3ft tall, hence I've been printing in components little by little. Originally I was relying on using a joint based system to connect it all and double down on its adhesiveness with super glue. But I'm starting to notice that the super glue isn't that strong of an adhesive for the object to maintain its connectivity as well as hold weight within in down the line.

So I was wondering if anyone has any solutions to how I can create a more adhesive unit that can hold weight? because my only idea as of now is to use car putty or body filler like how people used for pepakura based projects.

Any help would be greatly appreciated, down below are some attachments of what I currently have so far and the scroll i'm aiming to model it after !!

Are these pieces you're modeling yourself? If the stepped circle isn't intentional, you can definitely get a smooth circle shape with some adjustments to your model and/or export process.

ID10T

Sr Member

You could also use an epoxy, like the JB Weld clear stuff. (Home Depot carries it- two ~8oz bottles) It’s not as strong as the regular gray stuff, but it’s plenty strong. And clear, but sanding it will turn it white of course.

Billed as a “five minute” epoxy, that’s just the working window. It cures overnight.

I bought it to reconstruct a rusted snorkel on my Land-Rover and I’ve found many other uses since. And pretty cheap for the volume you get.

Billed as a “five minute” epoxy, that’s just the working window. It cures overnight.

I bought it to reconstruct a rusted snorkel on my Land-Rover and I’ve found many other uses since. And pretty cheap for the volume you get.

Hi al!,

Just finished reading up all the previous posts, and I figured I'd reach out in this forum since it dedicate to getting better at prop making using 3d printers. So I currently have a Longer Pro 3D printer, slicing with Simplify3D and i've been using PLA filament for most of my projects. I've currently been building a Naruto Ninja Scroll to hold some documents within it. The total build is gonna be a little bit over 3ft tall, hence I've been printing in components little by little. Originally I was relying on using a joint based system to connect it all and double down on its adhesiveness with super glue. But I'm starting to notice that the super glue isn't that strong of an adhesive for the object to maintain its connectivity as well as hold weight within in down the line.

So I was wondering if anyone has any solutions to how I can create a more adhesive unit that can hold weight? because my only idea as of now is to use car putty or body filler like how people used for pepakura based projects.

Any help would be greatly appreciated, down below are some attachments of what I currently have so far and the scroll i'm aiming to model it after !!

I've had good luck with CA glue but if you want more then you can use a combo of ca and e6000.

If you made that model yourself you could also model some spots where you could insert some wooden dowels etc to add strength.

here is a good video on orientation

And this is a good one for support theory

And this is a good one for support theory

AmazinSpiderboy

New Member

Im gonna try out Gorilla Glue and hopefully that makes the world of a difference. Im using a wood PLA mix so do you think that it would be better to use wood based gorilla glue or the clear kind of gorilla glue?? Also I did make the model using Rhino and Sketchup but im not too worried about the shape as im planning to wrap a cloth like fabric on it multiple times so it should hopefully hide most of the imperfections!I'm a fan of Gorilla Glue Clear for PLA. It's much less brittle than CA, and it doesn't foam up like their regular formula.

Are these pieces you're modeling yourself? If the stepped circle isn't intentional, you can definitely get a smooth circle shape with some adjustments to your model and/or export process.

AmazinSpiderboy

New Member

Sounds like a pretty good method if it worked for a Land Rover snorkel reconstruction hahah, I'll give that a run if the gorilla glue gets method falls short for whatever reasonYou could also use an epoxy, like the JB Weld clear stuff. (Home Depot carries it- two ~8oz bottles) It’s not as strong as the regular gray stuff, but it’s plenty strong. And clear, but sanding it will turn it white of course.

Billed as a “five minute” epoxy, that’s just the working window. It cures overnight.

I bought it to reconstruct a rusted snorkel on my Land-Rover and I’ve found many other uses since. And pretty cheap for the volume you get.

Evening Newbs

New Member

I'd still go with the clear Gorilla Glue for wood-fill PLA. It bonds well to wood, but I don't know how well PVA glue bonds to PLA. I would guess not very well.Im gonna try out Gorilla Glue and hopefully that makes the world of a difference. Im using a wood PLA mix so do you think that it would be better to use wood based gorilla glue or the clear kind of gorilla glue?? Also I did make the model using Rhino and Sketchup but im not too worried about the shape as im planning to wrap a cloth like fabric on it multiple times so it should hopefully hide most of the imperfections!

Thanks for posting these! So my take-away is that warping and other artifacts on the supported surface are normal - would that be accurate?here is a good video on orientation

And this is a good one for support theory

I’m just trying to figure out if what I’m seeing is typical or if there’s something in my process I can tweak.

Thanks again for the help!

Sean

TazMan2000

Master Member

For gluing PLA, I have always used Mercury Adhesives CA glue. Its very strong. So much so, that I just spent 2 hours removing an incorrectly glued piece off of copper pipe by using a moto tool. I'm sure that there are different formulation for very manufacturer, that have different degrees of strength (and odour), not to mention viscosity. I also use 5 minute epoxy when I need a little time positioning the parts.

TazMan2000

TazMan2000

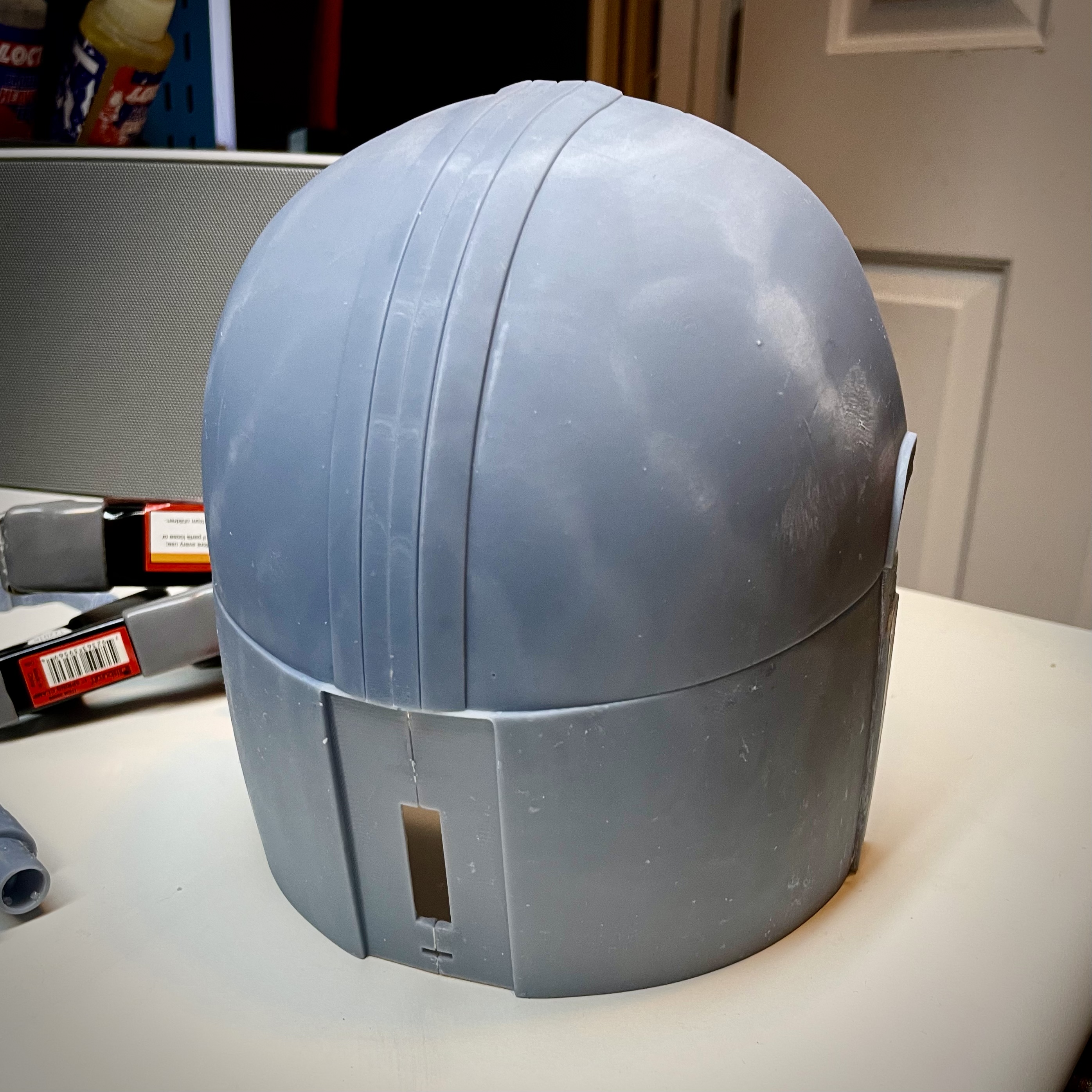

Been working on a secret project…

One of our neighbor’s celebrated his 8th birthday, and as he has recently been bit by the Mandalorian bug, I’m printing him a 3/4 scale helmet. I thought this would also be a good exercise for me to print a larger piece that’s been broken into sections, along with learning how to join pieces together.

For the most part, the pieces have needed little/no prep work to join up, aside from the soft corner I posted above. I’ve been doing the initial joining with Gorilla Super Glue and then going back over with some of the AnyCubic resin and curing it with a UV flashlight.

Files are from Great Ape Studio.

Sean

Back quarter:

Back half dry fit:

Top half put together. This will need a little sanding to touch up the seams:

One of our neighbor’s celebrated his 8th birthday, and as he has recently been bit by the Mandalorian bug, I’m printing him a 3/4 scale helmet. I thought this would also be a good exercise for me to print a larger piece that’s been broken into sections, along with learning how to join pieces together.

For the most part, the pieces have needed little/no prep work to join up, aside from the soft corner I posted above. I’ve been doing the initial joining with Gorilla Super Glue and then going back over with some of the AnyCubic resin and curing it with a UV flashlight.

Files are from Great Ape Studio.

Sean

Back quarter:

Back half dry fit:

Top half put together. This will need a little sanding to touch up the seams:

That looks good!

He's going to love it!

Thanks!

Good news is - he does love it!

Bad news is - it’s too small…

Worse news - the kids were trying to force it onto their ends and snapped it…

I find it interesting that it broke where it did. Good to know the seam lines were pretty strong.

I learned a lot with this one. Off to print another (slightly larger) one!

Sean

TazMan2000

Master Member

Unfortunately the brittleness of most resins aren't great for printing wearable helmets. One drop and they shatter. There are more expensive resins that may do the trick, but I haven't tried them out. You can still fix that break and have a small scale display piece.

TazMan2000

TazMan2000

I used Elegoo ABS-like rapid resin for the Silverhand grips I made, and it's not brittle, has a little bit of flex to it in fact. I don't know if it would work for a helmet, or not shatter if dropped, but I'm damn happy with the grips!

Thanks! I’m starting to research flexible resins for my upcoming Mando build, so I’ll check it out!

Sean

Similar threads

- Replies

- 1

- Views

- 346

- Replies

- 3

- Views

- 595