OK,

I thought I'd try and pull all the info on everything that's been laid out here so far...

1. The tab at the front of the door latch is cut off just short of the shroud and is attached with a #4-40 x 1/2" standard flathead screw.

2. There is a hole in the center of the door catch.

3. There is only 1 recharge pin on the saber and that is in the rear position on the side opposite the test lamp switch.

4. The bulb guts were removed with the middle section possibly being the only part used ( to hold the pins).

5. The recharge port button may or may not be a tire valve. Some found parts are very similar but not exact.

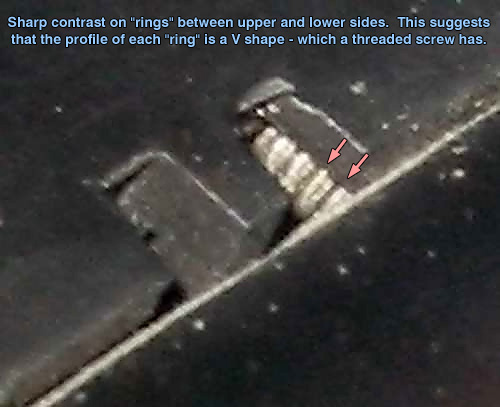

6. The control box has screw heads visible on top, but are covered over by tape, paint or both.

7. There is a screw or spring visible on at least the front cylinder of the control box (seen through the side slots and possibly also from the front)- Material unknown

8. There is a tube of some sort visible through the "recharge port" (behind the "tire valve") and through the test lamp switch.- Material unknown

9. The flash base may or may not be a Graf. Debate stands on the color of the tube, texture of the finish and whether or not an "L slot" is visible under the mid-band.

10. The base of the flash, where the Linhof assembly is, is one of the following:

a. a graflex bottom with an epoxy/ resin filling replacing the whole plate,

b. a graflex bottom with a washer or metal disc epoxied to it.

c. a standard graflex base with some resin filling in the copyright info and possibly filling in a dent,

d. a replacement base with either a metal disc epoxied on or filled with epoxy/ resin

11. Grips are either hard plastic or smaller metal T-Track that has been dipped in plastic.( or cheese

)- Material Unknown

12. The holes in the base by the grips line up with the spacing of the Luke ESB 6 grip pattern, but glue/ epoxy was most likely used as well for stability.

13. The profile of the grips match the ANH grips closer than the ESB grips. Possibly scabbed from an ANH stunt or Hero

13. This is still one REALLY ugly saber and it keeps getting uglier the longer we look at it. (Not that it's keeping me from making one

)

Did I miss anything?