Originally posted by synasp@Feb 5 2006, 10:59 PM

Wonderful. Well, I'm eager to see where this goes.

Are there definitive measurments?

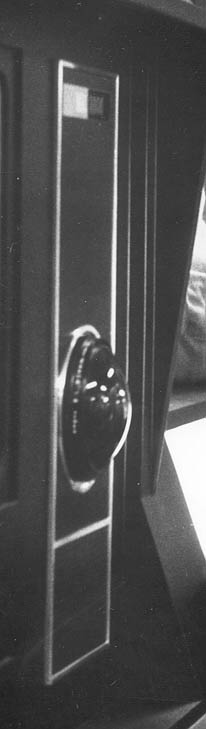

edit: just an idea... but why are there so many screws? Do you guys think this was scratch built, or a found item?

[snapback]1177146[/snapback]

To me it looks scratch-built, but using professionally-milled and drill-tapped frame pieces. Definitely the result of blueprinting.

The way I'd design it, there would be no visible screws, but rather extruded aluminum with threaded holes in the rear. The face and grill would be one stamped aluminum plate, the lens ring and upper grill border would be machined aluminum, and the lens would be injection molded polycarbonate (Lexan). The battery case, LED, sound board, speaker, sensors, and switches would all be be off-the-shelf components held in place by a secondary stamped aluminum or Phenolic plate with screws, PEM nuts, and spacers. The front cosmetic plate would be stenciled and both it and the rear plate would fit into slots and recesses built into the extruded sides:

The result will be a frame-like assembly with 45-degree seam hairlines in the corners or vertical seam hairlines colinear with the inside edge of the frame.

I'll better illustrate the differences in the 3D CAD model - this is just a quick schematic.

It would of course be more aesthetic to machine the frame out of a single blank of aluminum to avoid any seams at all, however you'd be looking at major milling and cutting = $$$. :unsure

- Gabe