You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Firefox MIG-31 movie aircraft

- Thread starter Firefox3D

- Start date

Firefox3D

Well-Known Member

Had a bit of an epiphany, realising printing the 1/48th kits doesn't really make sense, it takes so long and if you get a glitch it's going to be expensive and time consuming. So thinking about casting, and realised the way you mould large sculptures - a thin rubber mould skin then plaster with cloth over to hold the form. But instead of the plaster I can print an ABS custom outer mould in two halves so I only need 5mm or so of rubber and can cast the main body part in one with no seam lines to worry about.

Will still print some of the smaller parts that would be difficult to cast, and won't be using the black Photocentric resin as I found out it can react with acrylic paints, printed a dash at 1/48th in the Makerjuice SF which came out great, much sharper than when I tried before, I thought the resin didn't hold fine detail well, but it does. Also I think my new diode is better than the one I accidentally killed, so win-win.

Will still print some of the smaller parts that would be difficult to cast, and won't be using the black Photocentric resin as I found out it can react with acrylic paints, printed a dash at 1/48th in the Makerjuice SF which came out great, much sharper than when I tried before, I thought the resin didn't hold fine detail well, but it does. Also I think my new diode is better than the one I accidentally killed, so win-win.

TazMan2000

Master Member

It sure looks black in that short documentary. Wouldn't having a model painted blue disappear in a blue screen process?

TazMan2000

TazMan2000

Firefox3D

Well-Known Member

It sure looks black in that short documentary. Wouldn't having a model painted blue disappear in a blue screen process?

TazMan2000

It's down to lighting, the test paint I have looks virtually black in lower light.

The reverse bluescreen process is described in the Cinefex article I posted a while back, link again here

Cinefex - Google Drive

Relevant part is page 53-55.

Realised reading it the text is exactly the same as the video.

TazMan2000

Master Member

Sorry, I was confused by appearance to authenticity since you are actually replicating the movie aircraft.

TazMan2000

TazMan2000

TazMan2000

Master Member

Any updates?

TazMan2000

TazMan2000

Firefox3D

Well-Known Member

***Warning techy/nerdy stuff follows***

Sort of, I was getting disheartened by trying to print 1/48th parts on the Form 1 printer and the layer banding/shifting messing up the really fine detail. As I was going to bed a couple of weeks ago I had a brainwave on how to print better high detail parts. The Photocentric printer has a 2048 x 1536 9.7" screen with a 0.09mm pixel resolution. The flood of new printers on the market use the same Sharp 1440 x 2560 5.5" 0.043mm pixel screen.

After hacking into the Photocentric printer, pretty easy as it runs on a Raspberry Pi and the I guessed the default password might be photocentric, bingo I was in.

Cloned the boot SD card so if I screwed it up I could get it back. This turned out to be the biggest headache as I had to set up a linux virtual pc as all other software kept giving errors reading the the dual fat32 ext4 partitioned SD card. Needed a linux desktop to easily navigate the file structure anyway.

Received the 5.5" screen and driver board a few days ago, then came the headache of getting it to run, luckily found a post on a forum with the config setting to get it running. Then had to work out which setup files for the software needed editing as the image was rotated 90 degrees and squished. Once I found where the software was running from it was just a case of changing the resolution and pixel size settings in two files.

Made the mounting for the screen yesterday and ran a test print with estimated exposure times, which failed after the first few layers. Started another as I was going out today, got a bit further but still failed, darn.

Just now did a search for 5.5" screens with daylight reacting resins and found someone running a diy SLA printer, and turns out the exposure time need to be significantly longer. So about the run the 1/48th high detail exhaust again overnight.

It might all be for naught as I asked the UK reseller of the Anycubic Photon printers, which uses the same 5.5" high res screen if he would print the exhaust for me to see what it looked like, turns out not that much better than the standard Photocentric with half the resolution. I'm hoping the Photocentric can do better as the software runs anti-aliasing for the slice images which the Anycubic software doesn't.

Will post some pics tomorrow after hopefully a successful overnight print.

PS I have almost nearly finished printing all the parts for 3 x 1/18th models, but had a rush job to do before xmas.

Sort of, I was getting disheartened by trying to print 1/48th parts on the Form 1 printer and the layer banding/shifting messing up the really fine detail. As I was going to bed a couple of weeks ago I had a brainwave on how to print better high detail parts. The Photocentric printer has a 2048 x 1536 9.7" screen with a 0.09mm pixel resolution. The flood of new printers on the market use the same Sharp 1440 x 2560 5.5" 0.043mm pixel screen.

After hacking into the Photocentric printer, pretty easy as it runs on a Raspberry Pi and the I guessed the default password might be photocentric, bingo I was in.

Cloned the boot SD card so if I screwed it up I could get it back. This turned out to be the biggest headache as I had to set up a linux virtual pc as all other software kept giving errors reading the the dual fat32 ext4 partitioned SD card. Needed a linux desktop to easily navigate the file structure anyway.

Received the 5.5" screen and driver board a few days ago, then came the headache of getting it to run, luckily found a post on a forum with the config setting to get it running. Then had to work out which setup files for the software needed editing as the image was rotated 90 degrees and squished. Once I found where the software was running from it was just a case of changing the resolution and pixel size settings in two files.

Made the mounting for the screen yesterday and ran a test print with estimated exposure times, which failed after the first few layers. Started another as I was going out today, got a bit further but still failed, darn.

Just now did a search for 5.5" screens with daylight reacting resins and found someone running a diy SLA printer, and turns out the exposure time need to be significantly longer. So about the run the 1/48th high detail exhaust again overnight.

It might all be for naught as I asked the UK reseller of the Anycubic Photon printers, which uses the same 5.5" high res screen if he would print the exhaust for me to see what it looked like, turns out not that much better than the standard Photocentric with half the resolution. I'm hoping the Photocentric can do better as the software runs anti-aliasing for the slice images which the Anycubic software doesn't.

Will post some pics tomorrow after hopefully a successful overnight print.

PS I have almost nearly finished printing all the parts for 3 x 1/18th models, but had a rush job to do before xmas.

TazMan2000

Master Member

Sorry to hear about your troubles. I'm just happy that you are pushing through.

TazMan2000

TazMan2000

Firefox3D

Well-Known Member

First print was a bit underexposed, second one seems pretty darn close, bit tricky to measure as the difference between 33 secs exposure per layer and 37 secs was about 0.1mm!

Printed at 25um layers even under an eye glass I can't see the individual layers. I will probably cast these, but will need a superfine resin as the ends are about 0.4mm thick. Can anybody with experience with casting thin parts recommend a resin?

It was worth the effort as this is a print from the Anycubic Photon using the same hi-res screen, it is a bit overexposed, but I can also see the fact the image slices are not anti-aliased superimposed over the print, shows itself as a thick/thin stepping.

Just started a print of a 1/18th wing leading edge part to see how that comes out at 50um layers.

Printed at 25um layers even under an eye glass I can't see the individual layers. I will probably cast these, but will need a superfine resin as the ends are about 0.4mm thick. Can anybody with experience with casting thin parts recommend a resin?

It was worth the effort as this is a print from the Anycubic Photon using the same hi-res screen, it is a bit overexposed, but I can also see the fact the image slices are not anti-aliased superimposed over the print, shows itself as a thick/thin stepping.

Just started a print of a 1/18th wing leading edge part to see how that comes out at 50um layers.

Last edited:

Firefox3D

Well-Known Member

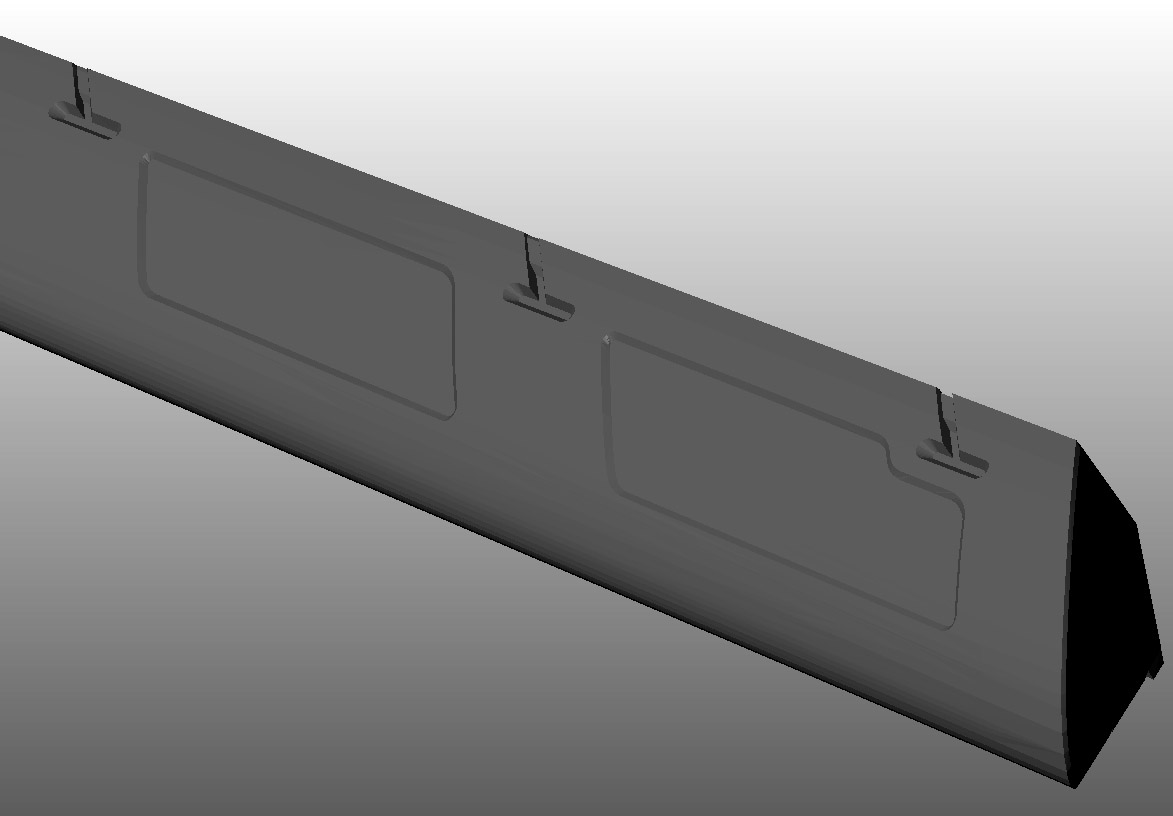

I had increased the detail of the wing leading edges to match the half-tone pattern photo-etch used on the original model, so went from this:

To this

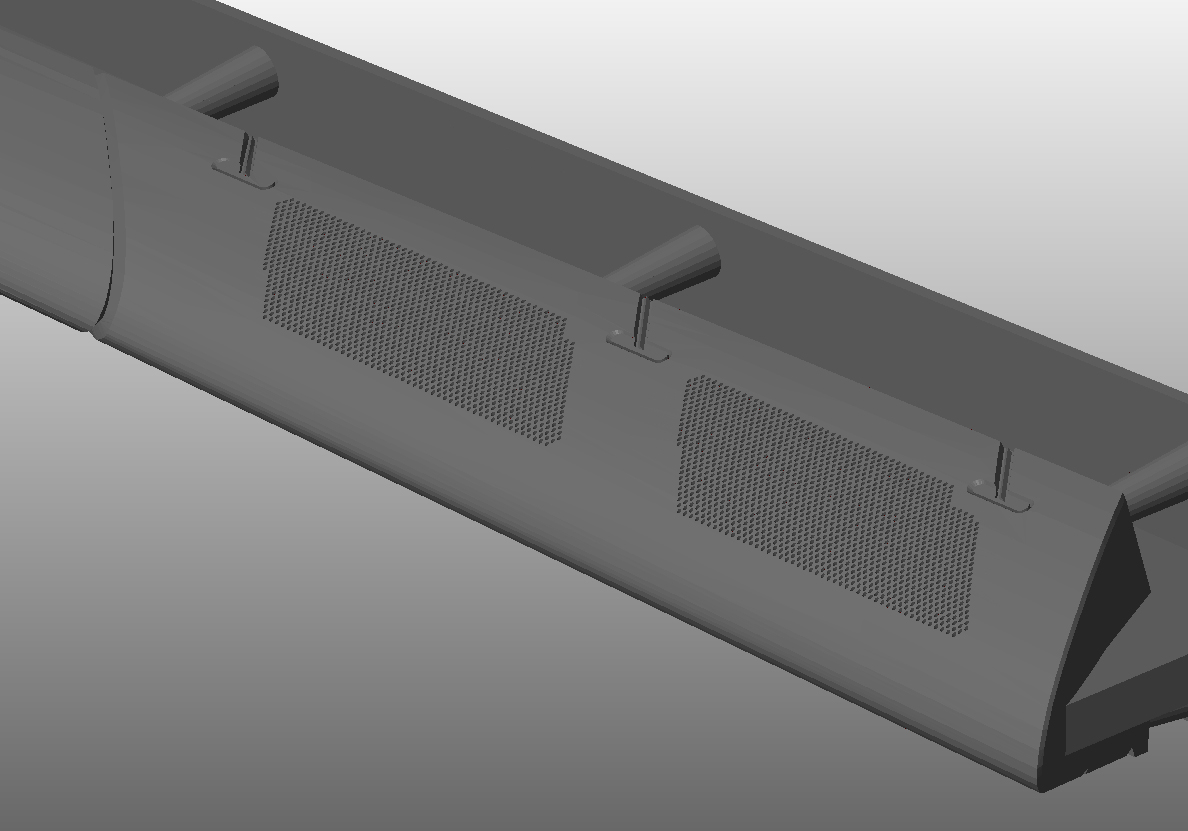

About 1400 0.25mm holes per section, and the result looks like this

Printed it horizontally for speed which caused the bit of distortion around the supports, but the result looks like mesh which is cool!

Some other bits I forgot to post

Gant at 1/18th on the Form 1 printer, will do this on the Photocentric printer, the layer shifting is pretty bad in places.

More exhausts in translucent red, this was a resin sample that came with the Photocentric printer, they don't make it now, shame looks nice, even though it's going to be painted.

To this

About 1400 0.25mm holes per section, and the result looks like this

Printed it horizontally for speed which caused the bit of distortion around the supports, but the result looks like mesh which is cool!

Some other bits I forgot to post

Gant at 1/18th on the Form 1 printer, will do this on the Photocentric printer, the layer shifting is pretty bad in places.

More exhausts in translucent red, this was a resin sample that came with the Photocentric printer, they don't make it now, shame looks nice, even though it's going to be painted.

rbeach84

Sr Member

You should contact the fellows at Resin2Detail (http://resin2detail.com/). They use the process of printing their masters and then casting in resin. The main guy (his name eludes me at the moment), who I've met before is a nice guy, a model 'geek' and very passionate. His sets use a mid-grey resin that is of excellent quality. Can't hurt to ask! ;^)

Cheers!

Cheers!

JediG60racer

Sr Member

.... holding breath patiently....

Firefox3D

Well-Known Member

Hi guys, still working on things, just been busy with projects to pay the bills.

I picked up another Photocentric HR printer silly cheap as it was presumed dead, turned out to just be corruption on the boot card, and a whole lot of clean-up from spilt resin. Now need another table/workbench as have run out of room! But now I can leave my original one with the small hi-res screen and have the second for normal printing.

Only have a few parts left to print to complete 1/18th kits, then need to sort out the 1/48th master for moulding.

I picked up another Photocentric HR printer silly cheap as it was presumed dead, turned out to just be corruption on the boot card, and a whole lot of clean-up from spilt resin. Now need another table/workbench as have run out of room! But now I can leave my original one with the small hi-res screen and have the second for normal printing.

Only have a few parts left to print to complete 1/18th kits, then need to sort out the 1/48th master for moulding.

Similar threads

- Replies

- 10

- Views

- 1,130

- Replies

- 9

- Views

- 704