You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Deckard's Sedan from Blade Runner build thread - Fujimi 1/24 model kit

- Thread starter Neon Nautilus

- Start date

Looking great! Soldering is tricky, but once you get it down, you will love it. The Main reason for flux is to keep the joint from oxidizing while you are heating up the brass, this will then assist in solder flow in the joint. The flowing action is called 'capillary action'. It is the 'suction' pulling the solder into a clean tight joint. It like when you coaster sticks to the table with water under it, and you cannot lift it without prying it up.

If you search jewelry soldering, you will see a lot of these techniques in use. There are also different hardnesses of solder, easy, medium and hard. They melt at different temps, low to hight temps. You can start off with hard and then to easy solder if you have to solder the same piece multiple times. Takes practice, but if one person can do it, so can another.

Hope this helps. Looking forward to more!!

When soldering multiple parts, you can use steel binding wire. It is a thin steel wire you can easily wrap around the parts being soldered together. Yes, you can solder the binding wire to your piece if you are not careful. To prevent this, you can use white-out on areas or parts you don't want the solder to stick to.Thanks Analyzer, it's definitely useful for larger more solid pieces but you can't use it for everything. Plus multiple joins on the same piece get tricky as you could reheat solder that's already cooled leading to pieces moving about

If you search jewelry soldering, you will see a lot of these techniques in use. There are also different hardnesses of solder, easy, medium and hard. They melt at different temps, low to hight temps. You can start off with hard and then to easy solder if you have to solder the same piece multiple times. Takes practice, but if one person can do it, so can another.

Hope this helps. Looking forward to more!!

Thanks for the kind words Sym-Cha. I wasn't aware of that head sculp, will have to see if I can track it down.This beautiful build screams for an added action figure ... are you aware you can get a very nice detailed head sculpt of Deckard in 1/24th scale?

View attachment 1587492

You will have to scratchbuild a 1/24 scale body to go with this head.

Chaïm

Thanks so much for the knowledge share srspicer, really appreciated!Looking great! Soldering is tricky, but once you get it down, you will love it. The Main reason for flux is to keep the joint from oxidizing while you are heating up the brass, this will then assist in solder flow in the joint. The flowing action is called 'capillary action'. It is the 'suction' pulling the solder into a clean tight joint. It like when you coaster sticks to the table with water under it, and you cannot lift it without prying it up.

When soldering multiple parts, you can use steel binding wire. It is a thin steel wire you can easily wrap around the parts being soldered together. Yes, you can solder the binding wire to your piece if you are not careful. To prevent this, you can use white-out on areas or parts you don't want the solder to stick to.

If you search jewelry soldering, you will see a lot of these techniques in use. There are also different hardnesses of solder, easy, medium and hard. They melt at different temps, low to hight temps. You can start off with hard and then to easy solder if you have to solder the same piece multiple times. Takes practice, but if one person can do it, so can another.

Hope this helps. Looking forward to more!!

Hi All, hope you're having a good weekend. I've got a little more work done on the Sedan's interior.

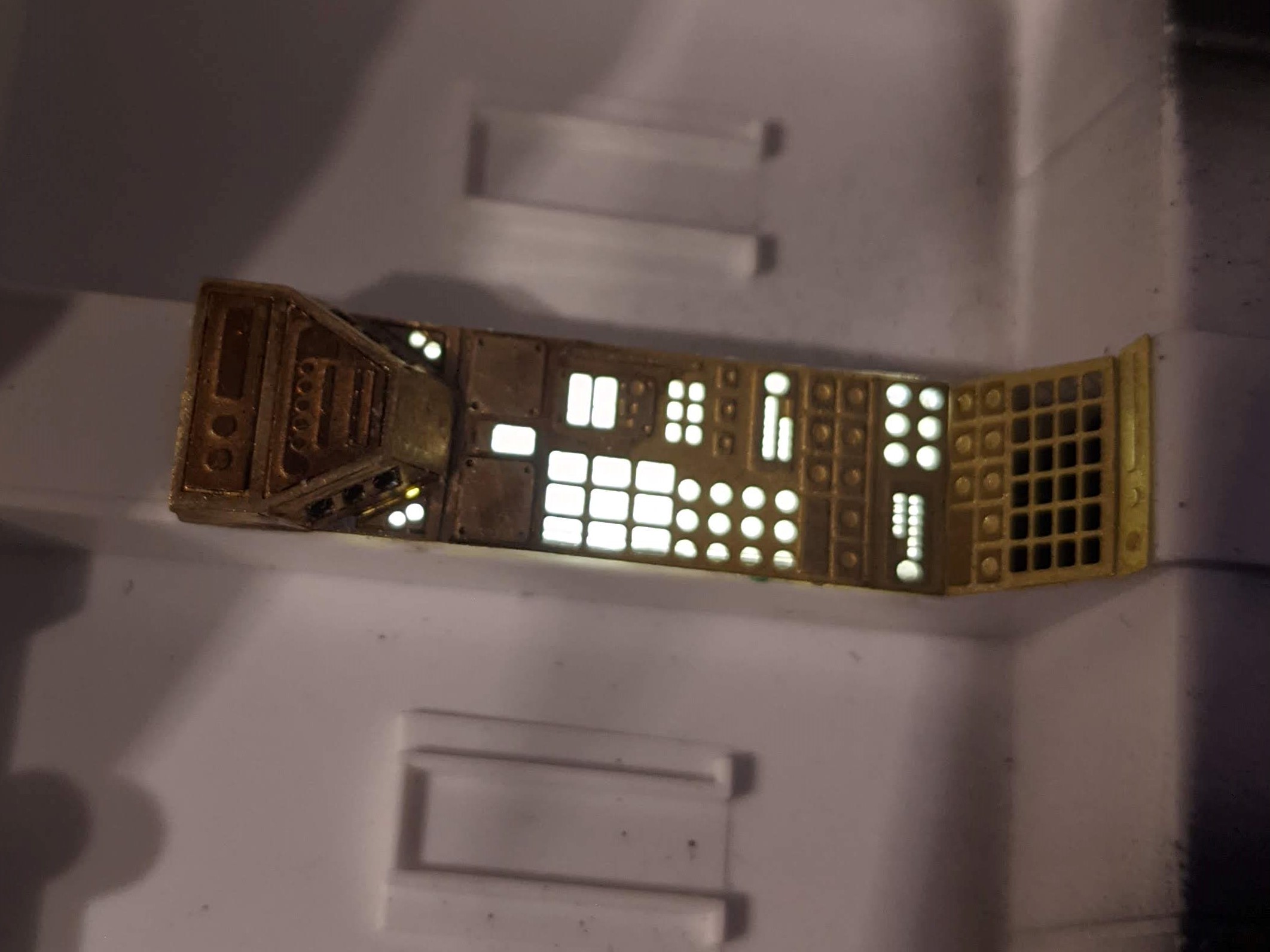

This update covers work on fitting the photoetch centre console made in a previous post.

I'd already cut out the holes needed for the two main panels, so first step was to apply CA around the edges on the plastic then line up and place the brass pieces in place.

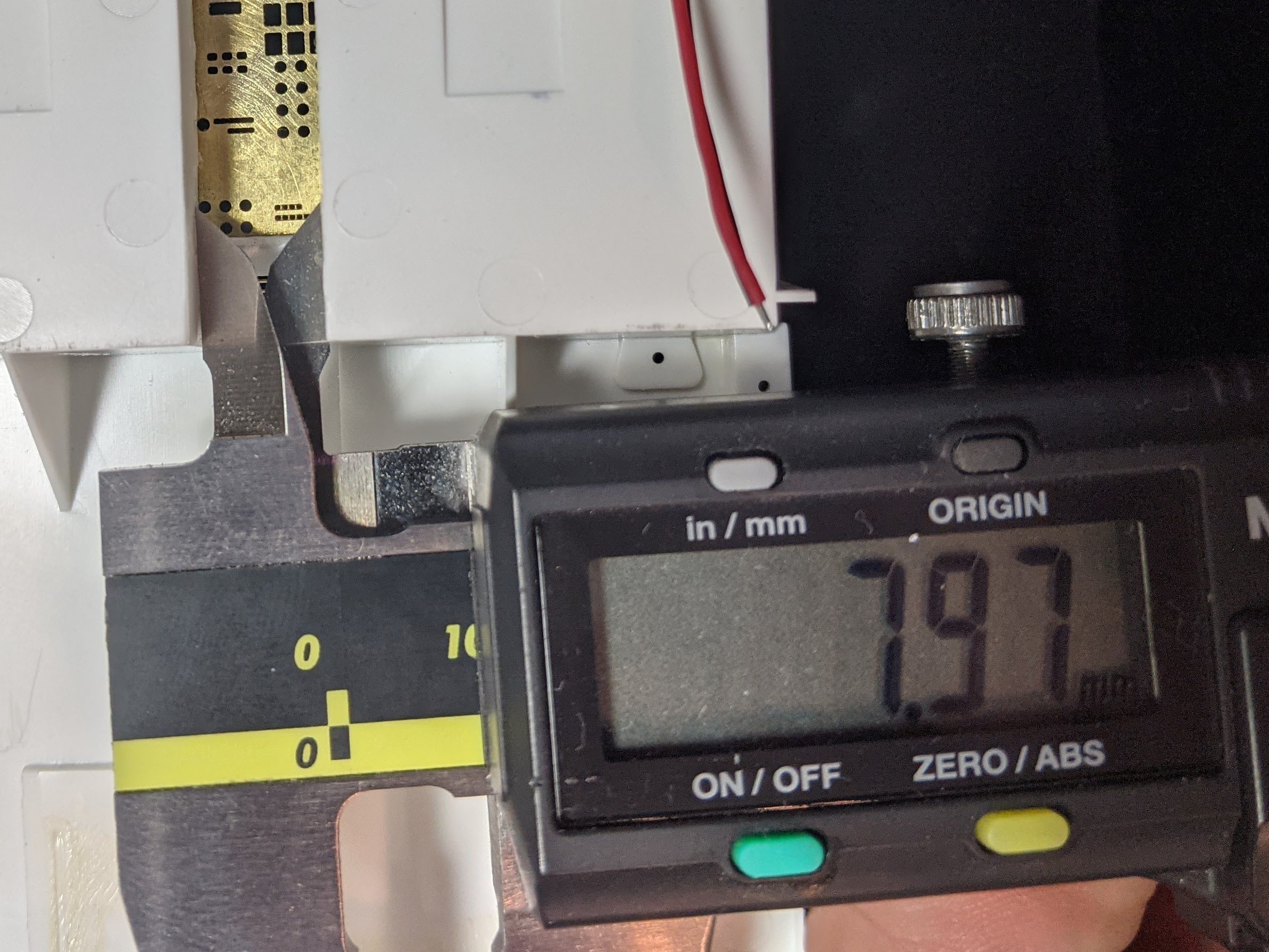

Next up I flipped the interior tub over and measured the width on the recess under the etch panel.

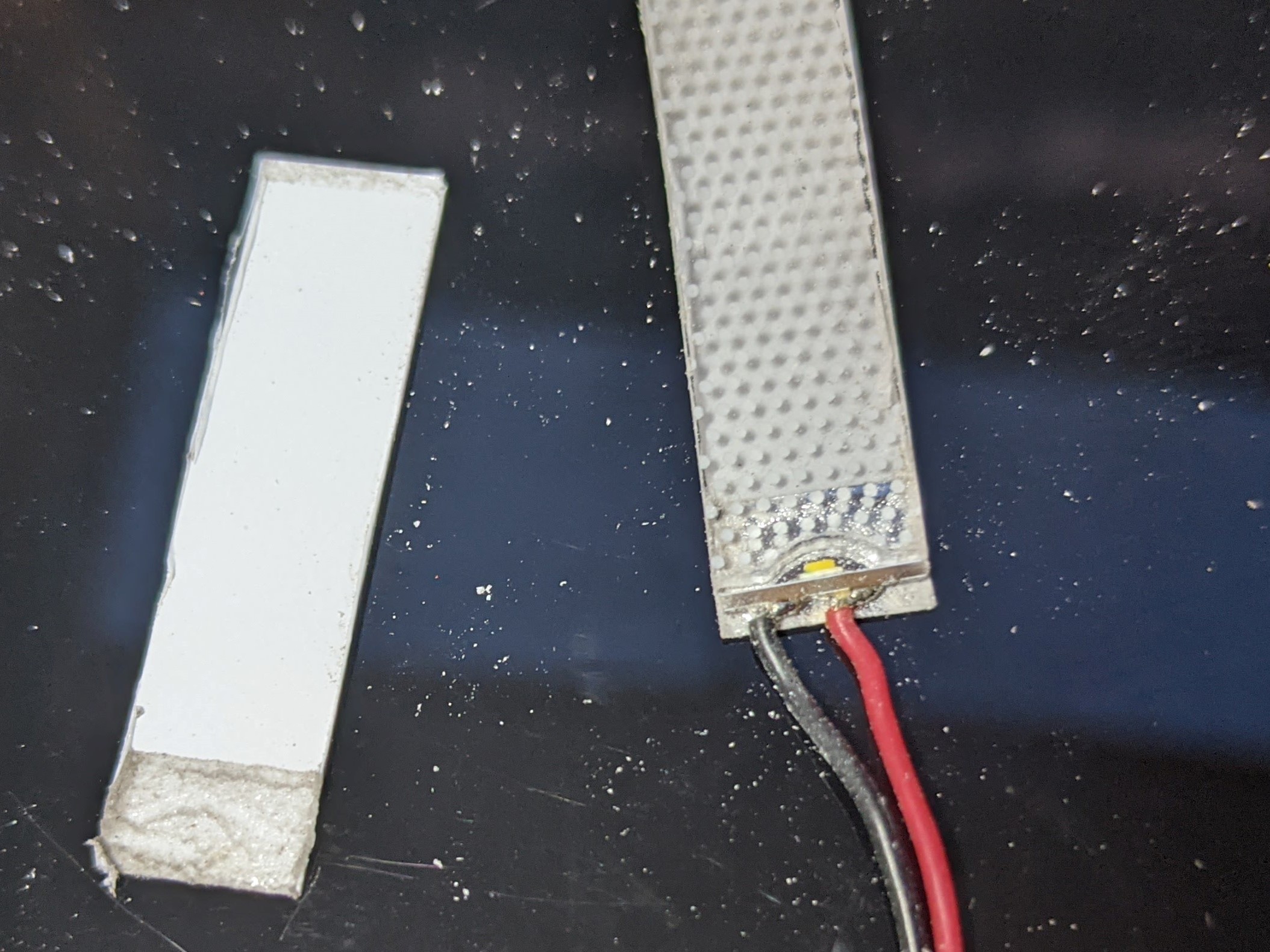

Suitable Marks were then made onto an 18mm x 30mm micropanel so I could cut it to fit the space.

I've been cutting these panels with a grinding disk in my rotary tool. I have a bench clamp designed to hold the tool in place which is great for this kind of job. It's far easier to offer the part up to the tool than trying to move the tool along a straight line.

I take most of the unwanted material off in the first pass, but don't go right up to the edge.

On the second pass I creep up on the line gently to get it nice and neat.

The edges are then refined with a hand file and test fitted, filed, test fitted, filed again until they fit well.

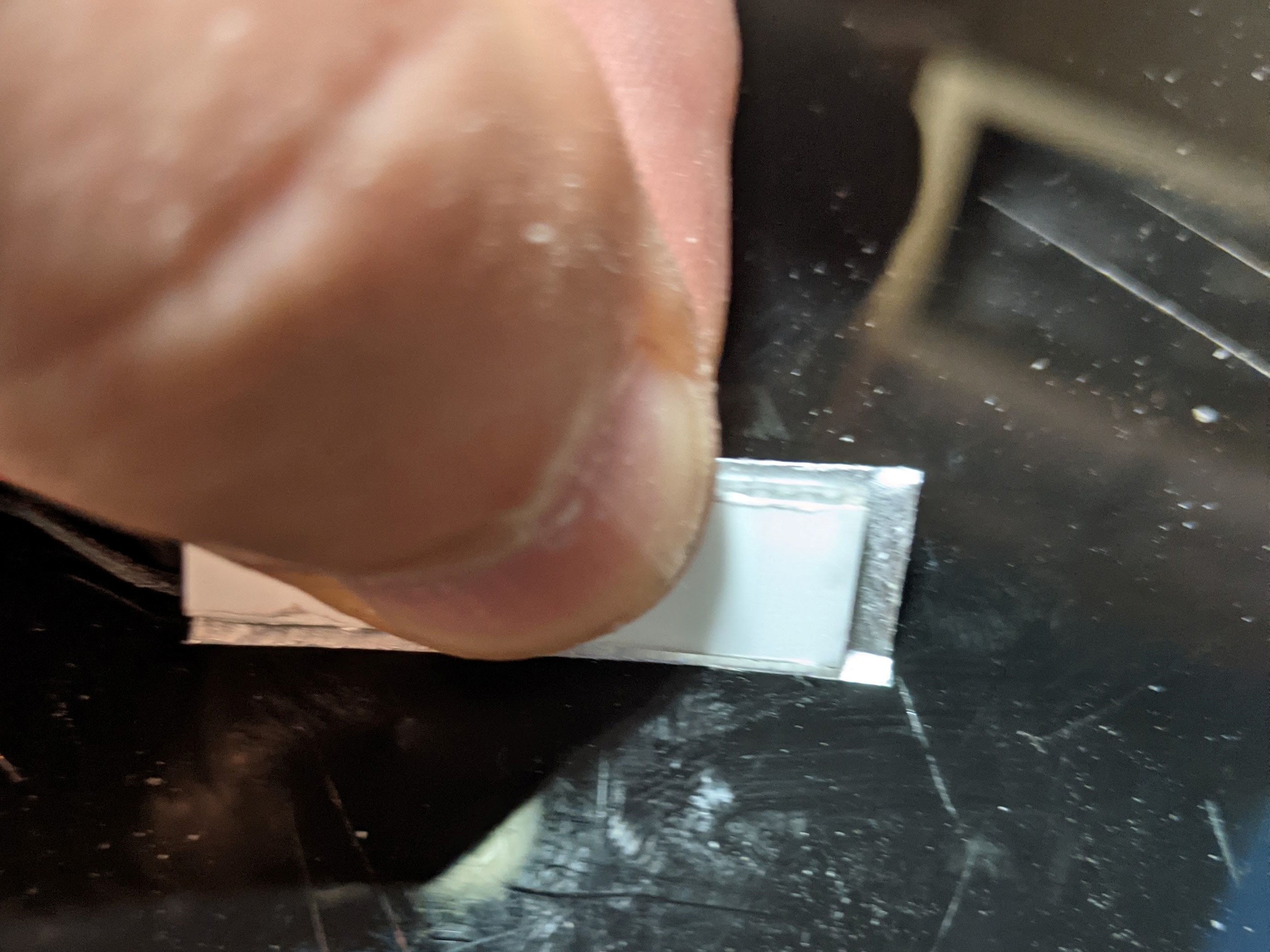

I make them a touch undersized as I'll be adding aluminium tape around the edges as a light blocker.

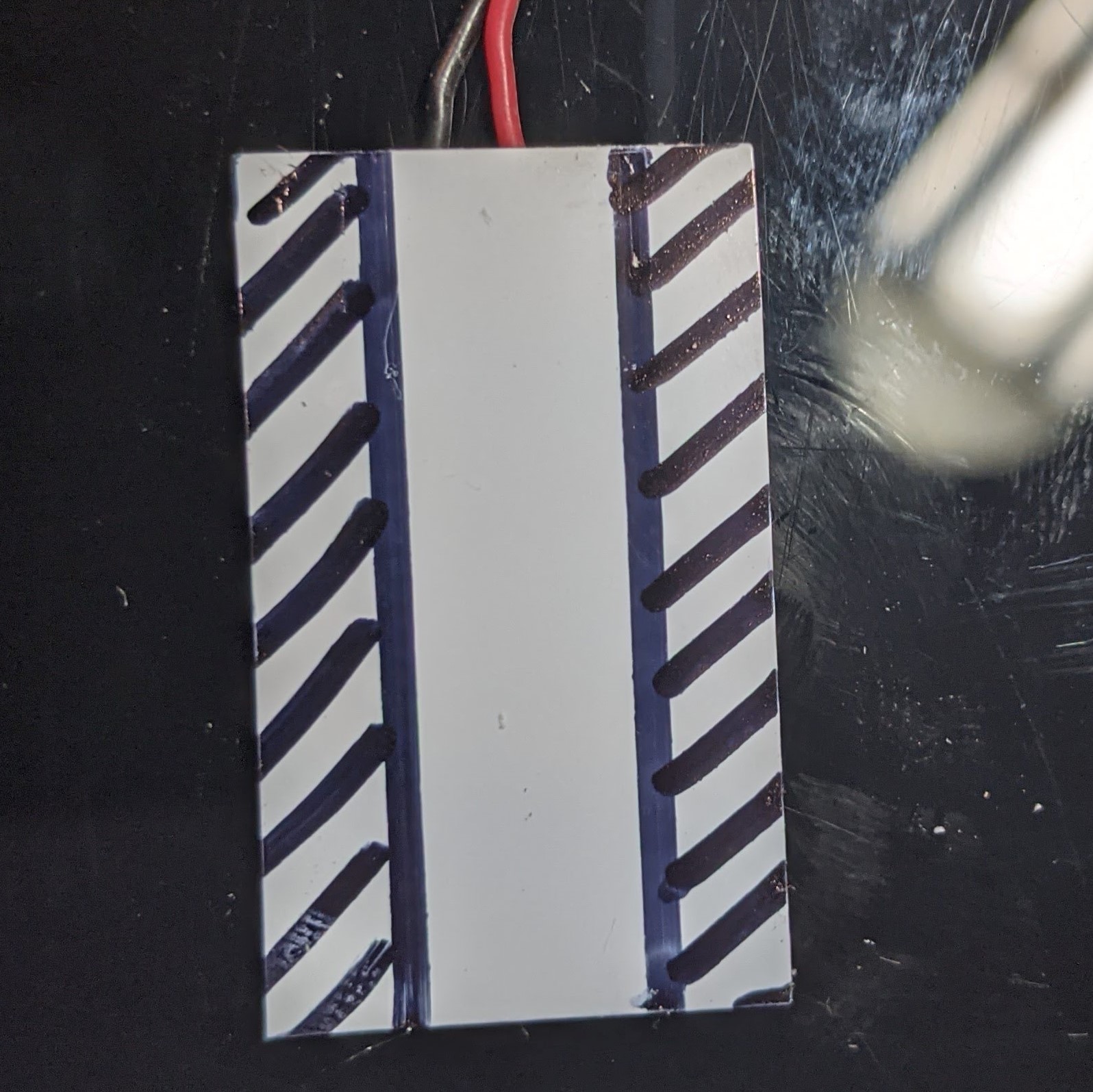

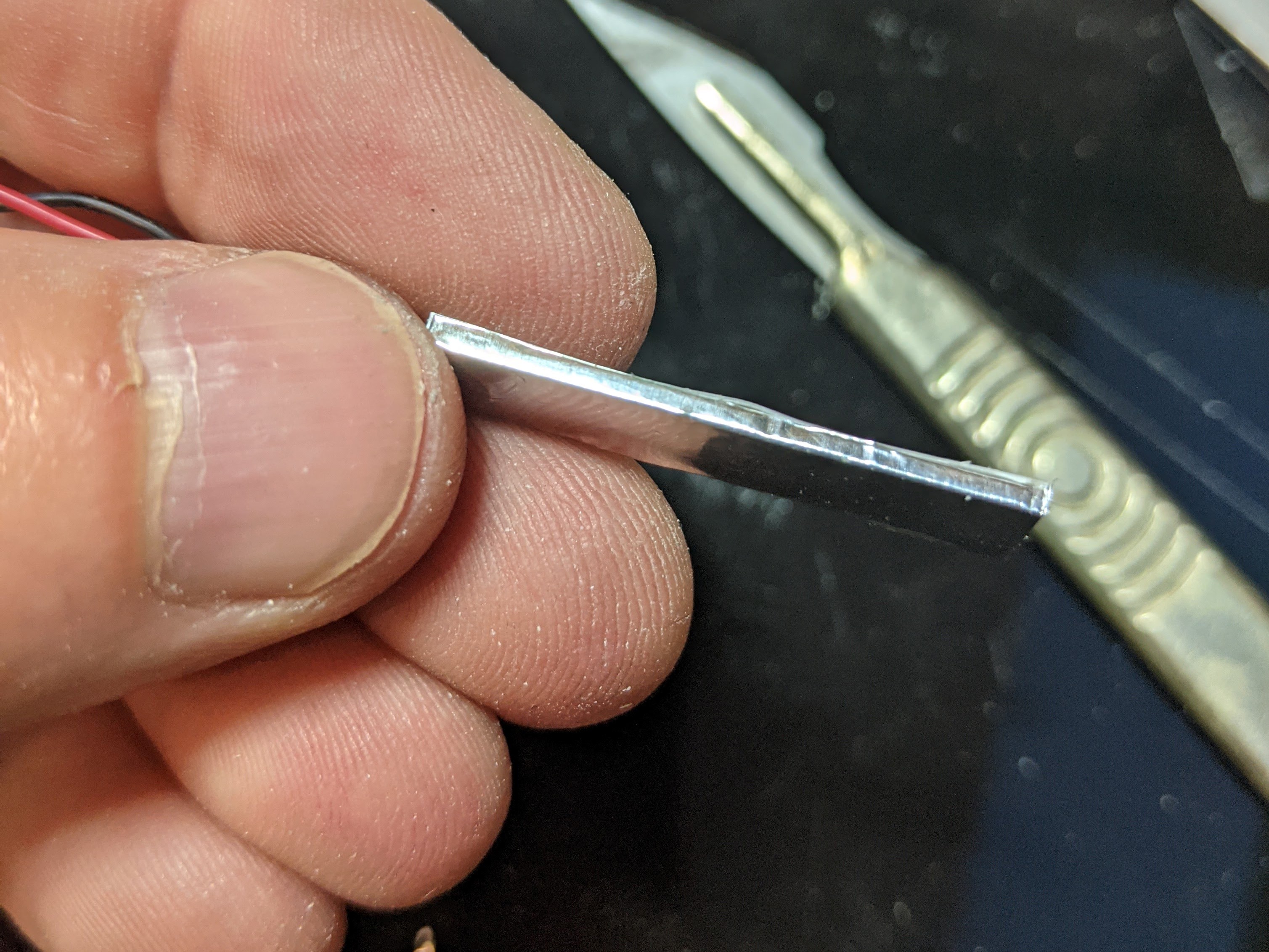

Once I've got the width down I peel off one side of the panels diffuser. The panels are like a sandwich with a core of an acrylic panel and the LED with a thin diffuser material either side.

I then cut a piece of aluminium tape and stick it down over the exposed acrylic.

The tape is then trimmed leaving a small lip all the way around the edges of the panel.

I then drag the panel along a firm flat surface so that the tape is neatly wrapped around the edge. This is repeated on the three exposed sides and any excess trimmed off.

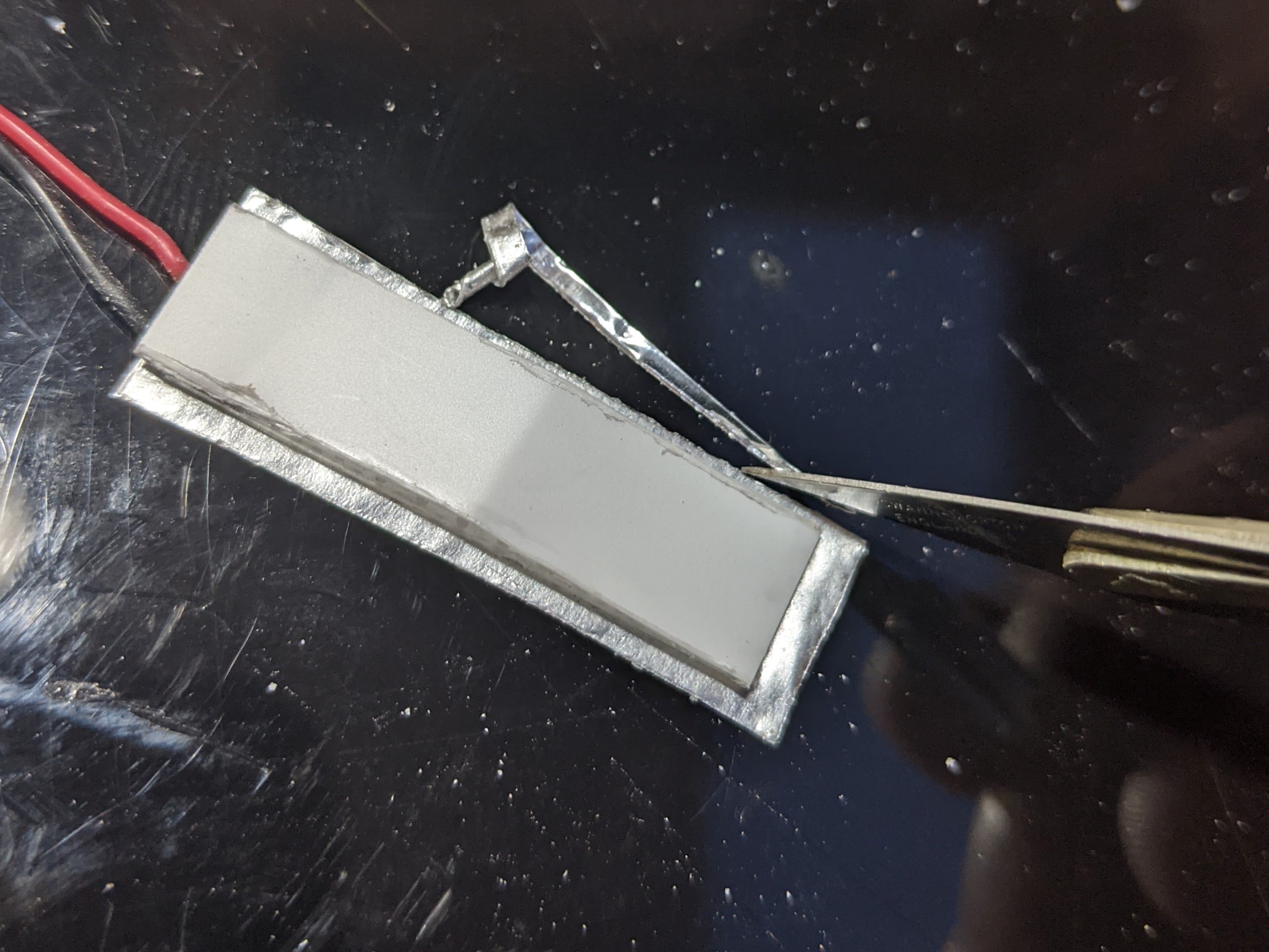

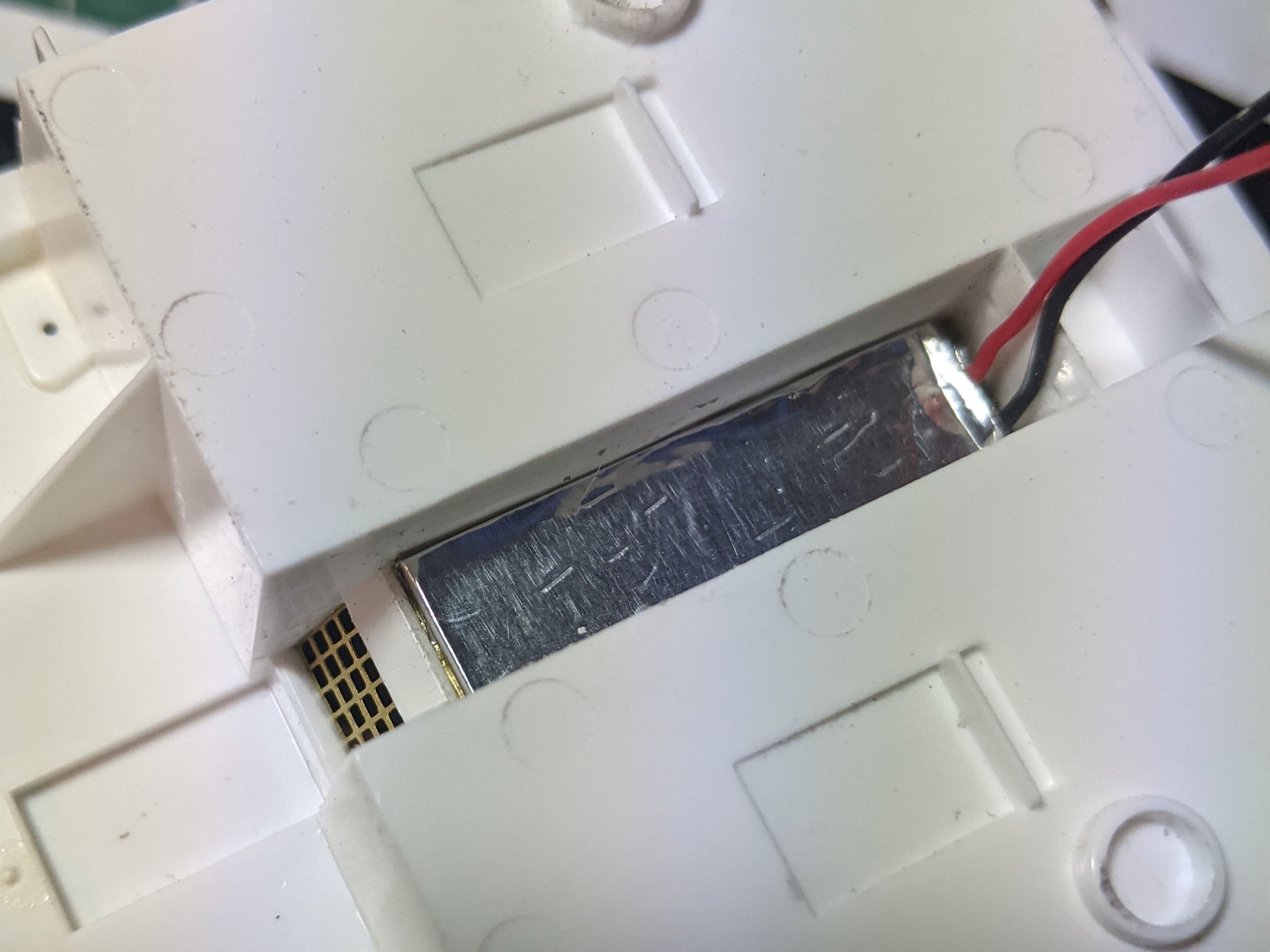

The panel now fits in the recess to light the console and is completely, definitely, without doubt, 111% light blocked...

Wait... What!!!!

I forgot to cover the end of the light panel so it was spilling out from the back of the LED.

Little bit more tape...

...and it's looking great.

This update covers work on fitting the photoetch centre console made in a previous post.

I'd already cut out the holes needed for the two main panels, so first step was to apply CA around the edges on the plastic then line up and place the brass pieces in place.

Next up I flipped the interior tub over and measured the width on the recess under the etch panel.

Suitable Marks were then made onto an 18mm x 30mm micropanel so I could cut it to fit the space.

I've been cutting these panels with a grinding disk in my rotary tool. I have a bench clamp designed to hold the tool in place which is great for this kind of job. It's far easier to offer the part up to the tool than trying to move the tool along a straight line.

I take most of the unwanted material off in the first pass, but don't go right up to the edge.

On the second pass I creep up on the line gently to get it nice and neat.

The edges are then refined with a hand file and test fitted, filed, test fitted, filed again until they fit well.

I make them a touch undersized as I'll be adding aluminium tape around the edges as a light blocker.

Once I've got the width down I peel off one side of the panels diffuser. The panels are like a sandwich with a core of an acrylic panel and the LED with a thin diffuser material either side.

I then cut a piece of aluminium tape and stick it down over the exposed acrylic.

The tape is then trimmed leaving a small lip all the way around the edges of the panel.

I then drag the panel along a firm flat surface so that the tape is neatly wrapped around the edge. This is repeated on the three exposed sides and any excess trimmed off.

The panel now fits in the recess to light the console and is completely, definitely, without doubt, 111% light blocked...

Wait... What!!!!

I forgot to cover the end of the light panel so it was spilling out from the back of the LED.

Little bit more tape...

...and it's looking great.

Any Updates??This beautiful build screams for an added action figure ... are you aware you can get a very nice detailed head sculpt of Deckard in 1/24th scale?

View attachment 1587492

You will have to scratchbuild a 1/24 scale body to go with this head.

Chaïm

Hey propsculptor, thanks very much for your interest in this build.Any Updates??

I've not worked on it for a while. There's a couple of things that I'm not sure on the best way to approach so the kit got shelved. I will definitely be working on it again at some point though.

At present I'm completely absorbed in my Klingon Bird of Prey build. I've got an old AMT kit that I've stripped most of the heavily simplified details from and am scratch building new details to make as close as possible to the studio scale model. I've not posted any updates on the KBOP for a while but have a ton of pics that I'll be sharing soon.

Last edited:

To light the screens and probably all the interior panels I'm using something I discovered last year.

They're called micropanels. I purchased from a guy called 'NK Guy' who also goes by the name 'Age of Plastic' and curates the website 3dsf.info

View attachment 1580765

Well hey! How did I miss this post?

ijon

New Member

Hello thereWell hey! How did I miss this post?So great to see my micropanels out in the wild. Great work!

Hello therewill light panels 35x51mm return?

Hi. I'm afraid not. It costs a lot to commission the factory to manufacture the panels, and demand hasn't been high enough for me to cover all those costs. Sorry!

They're a great product. I've also used them for lighting the Paragrafix PE cockpit and your 3D printed corridor for Bandai's 1/72 Millennium Falcon.Well hey! How did I miss this post?So great to see my micropanels out in the wild. Great work!

Thanks ijon! I've not actually gotten around to painting the body of the spinner yet. This project has been shelved for a while as I've been concentrating on this: 1/350 Klingon Bird of Prey - Improving the AMT KitHi,

first of all awesome build with lot of details. I am building one too right now, I wanted to ask, could you please tell me what color did you use for main frame? Your red looks really nice and I have problem with choice. Also great gloss finish.

The red car pictured in one of the earlier posts is the full size original filming car that's in the Petersen Museum. My intention is to paint my model in a two tone maroon and bronze colour scheme as seen in the picture below. From what I can tell that is more accurate to Deckard's ground car than the all red version.

They're a great product. I've also used them for lighting the Paragrafix PE cockpit and your 3D printed corridor for Bandai's 1/72 Millennium Falcon.

Great paint job - the corridor looks perfect! How’d the cockpit turn out? (Though this is derailing the topic a bit!)

Cheers! The cockpit isn't quite finished yet. Quite a bit to figure out fitting the micropanels to the facets of the walls and ceiling. They work great for those white light bars. Will get back to it one day.Great paint job - the corridor looks perfect! How’d the cockpit turn out? (Though this is derailing the topic a bit!)

Thanks PAULH!Astonishing work.

Is there a Gaff head that matches this scale head that could be used for the Fujimi Spinner?This beautiful build screams for an added action figure ... are you aware you can get a very nice detailed head sculpt of Deckard in 1/24th scale?

View attachment 1587492

You will have to scratchbuild a 1/24 scale body to go with this head.

Chaïm

Sym-Cha

Master Member

Similar threads

- Replies

- 11

- Views

- 3,294