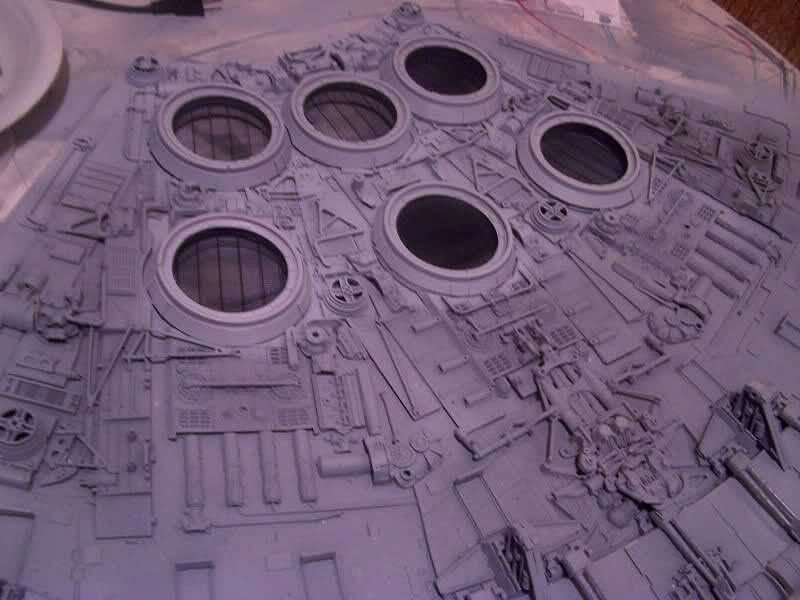

Right, here we go again guys!.

After quite a time of painful study of the cockpit & the fit of donor parts & orientation of the drilled holes & also the correct placement of the Panther strips, it is finally done, the schematic anyhoo!.

The tube size is definately 5 3/4", 6" & my original idea of 5 1/2" just don't work at all.

Also, the 9 holes were not drilled evenly spaced by ILM as is very evident when lining up the donors & especially the Panther strips to get the correct orientation. I know, I cut a tube, drilled the 9 holes, evenly spaced & yep, no go.:unsure

The drawing I have added here is 99% accurate, I'm that confident chaps. I can't fault it with all donors fitting as they should.

Regarding the Bandai Panther strips, you will need 2 fenders & 1 side-skirt. If you build it using solely kit parts as donors, no casts, then 2 kits required.

One interesting observation with the Panther side-skirt strips which end at the bottom of the cockpit, is that they taper in somewhat, from about 21mm in to 17.75mm which is very clear when you line up the Bandai King Tiger part.

I even counted the louvres between the holes as Wayne suggested to get the spacings for the holes, this did help too. Spacings ranged from 16 to 19 louvres, so quite some difference there!.

I'm going to try & get the new tube cut this week & the cone vac-formed as well. Made the buck to do the cone ages ago, but needed to be sure first on tube size.

Oh, the measures for the tube are:

Tube diameter = 5 3/4"

Side = 172.5mm

Top/Bottom = 132mm

Short Side = 93.75mm

I can email the schematic to anyone if the quality hasn't turned out here ok!.