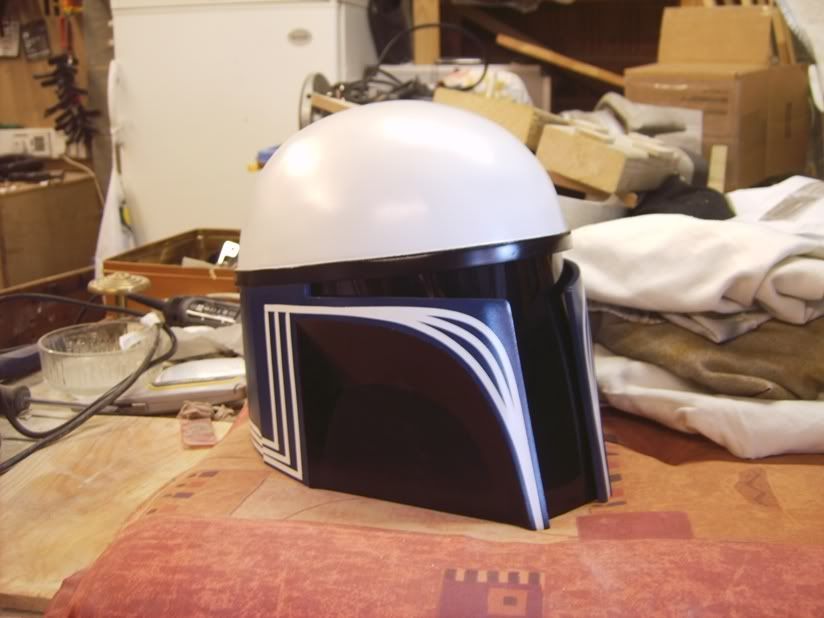

Re: Boba fett helmet pep build (my first build)

i need your help stryene lovers, i have never used the stuff and i dont know what im really looking for and need some advice, basically where can i buy it, or where do you recommend to buy it, im UK based if there are any shops that sell the same kind of product.

i think i need 2-4mm thickness sheets.

could really do with some advice, "help me RPF, you're my only hope"

Hi rosskow

I first want to say how impressed with your first build I am, it's inspirational stuff and no mistake :thumbsup I've not tackled pep yet, but I'm logging this as my definitive guide it's so good. Well done mate

hay R2, play back that message!

Here's a link to a uk based styrene supplier

Trylon - Vacuum Forming

For glue, go for one that bonds it rather than melts the styrene together as its much more forgiving if you make a mistake.

And here's a great paint peel/chip weathering effect I learned from IRONFETT for when you get round to doing the proper fett paint job:

Spot paint the areas you want to show through with chrome first (like the dent). Then use latex to paint whatever shape of the flecked or chipped bit you want it to be, allow to dry and add all your top coats until it's finished. Once your happy with the paint job, remove the latex to expose the chrome underneath and give the whole helmet a wash (not the soap kind of wash :lol). For a typical wash, use light to mid browns and black or other coloured to that effect to give it a dirty/dusty, used look. Hold the spray can at least 5-6ft away from the helmet in a wind proof area to just give a light dusting. Coat whole lid with a clear top coat, job done :thumbsup

As with most projects on this forum, there will usually be a time when you come round to moulding something.

I use eBay to source most of my moulding materials, and t's actually not too expencive on this side of the pond. Look up Easyflo 160 rotocasting resin.

If you make the mother mould out of fibreglass (the hard outer covering that makes the mould keep its shape) you could include a pole at the top between the parting line that you could place on a table or something to help rotate it. It would need reinforcing a bit, but it's a cheep option.

I watched countless hours of YouTube tutorials on moulding techniques and it's been an invaluable source of referance.

If you do go that route, the best piece of advice I ever had was...... ALWAYS use a release agent! Even if it says the product is self releasing. I've seen some of the results from the unfortunates who chose not to use a release agent and in some cases it was heart breaking stuff. May you never have that experiance in your hobby.

Peace