You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ANH grip cutting help

- Thread starter iXela

- Start date

Mouse Vader

Sr Member

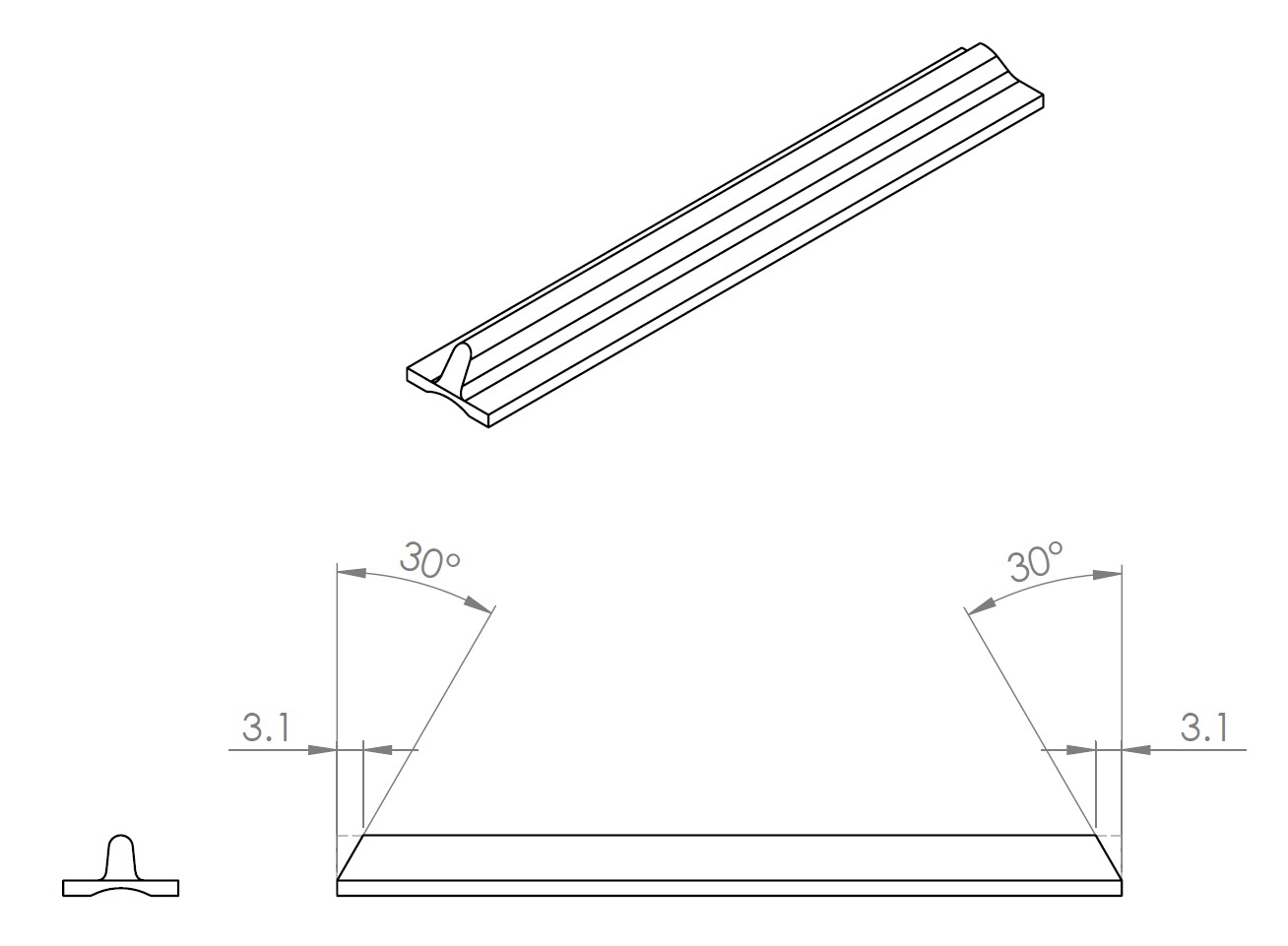

Depends on how you are approaching this. These props were not precision pieces but hand made. In all likelihood the chamfer on the T-track was done by eye with a file or hack saw. I'm not ware of anyone who's done a strip by strip 'measured' angle on each one. Neither do I know of any extant original from which measures were taken (unless you count the one Roger Christian tried to sell not so long ago.)

My advice in general, from your question, would be to make a card template with 30 deg. angle (protractor measure should be close enough) and file a bit - test against your former - file a bit more etc. until you're happy. 2nd cut (******* file) should do.

My advice in general, from your question, would be to make a card template with 30 deg. angle (protractor measure should be close enough) and file a bit - test against your former - file a bit more etc. until you're happy. 2nd cut (******* file) should do.

If you want to get crazy do a google search and there are 3D printed templates to help you match the angle for each track and you can use a saw, file, jewelers saw, coping saw, Japanese flush cut, etc, etc to follow that angle and cut it down.

Or as mouse said. Use a protractor and make the angle.

I’d also suggest googling “30° angle” and print that out, and you can make a cut template with that.

There are a LOT of ways to “skin a cat” as they say.

Or as mouse said. Use a protractor and make the angle.

I’d also suggest googling “30° angle” and print that out, and you can make a cut template with that.

There are a LOT of ways to “skin a cat” as they say.

another way you could do it:

-Print out on a piece of paper, an acute 60° angle template.

-Cut that out.

-Then transfer that angle onto two “mirrored” pieces of tape.

-position the tape equally on both sides of the T track.

-now you have a cut guide.

-secure your t-track near the edge of a flat surface.

-use a fine serrated blade to *rough* cut the profile. (Keep it a bit away from the tape edge)

-file or sand the rough cut until you “kiss” the 60° tape guides you’ve set.

-lightly finish sand or polish to a grit that blends with the rest of the track.

-Remove your tape and reuse it on the other tracks. (If your tape template has been damaged make new ones using the original printout)

if all else fails. Shoot roygilsing (wannawanga) a message and see what he recommends for his track!

-Print out on a piece of paper, an acute 60° angle template.

-Cut that out.

-Then transfer that angle onto two “mirrored” pieces of tape.

-position the tape equally on both sides of the T track.

-now you have a cut guide.

-secure your t-track near the edge of a flat surface.

-use a fine serrated blade to *rough* cut the profile. (Keep it a bit away from the tape edge)

-file or sand the rough cut until you “kiss” the 60° tape guides you’ve set.

-lightly finish sand or polish to a grit that blends with the rest of the track.

-Remove your tape and reuse it on the other tracks. (If your tape template has been damaged make new ones using the original printout)

if all else fails. Shoot roygilsing (wannawanga) a message and see what he recommends for his track!

I would avoid a “blade” like an exacto knife or drywall knife as you simply won’t get the kind of cut you’re looking for.

As always, “test” first. Test cut on the very end or corner or an inconspicuous/un-used area and make sure your tool is doing what you want.

I would personally recommend a flush cut blade (you pull it towards you and it has a fine tooth)...which should get you 90% of the way. then following with either a file or sanding pads to sand down to the exact edge where you need.

power tools can be overkill for this and could destroy the tracks unless you know exactly what you’re doing and have extreme control/understanding of the tool.

Even then, plastic will melt under a tool with a high RPM and you could deform and ruin it without caution.

So again, use a fine toothed saw and it should be fine

As always, “test” first. Test cut on the very end or corner or an inconspicuous/un-used area and make sure your tool is doing what you want.

I would personally recommend a flush cut blade (you pull it towards you and it has a fine tooth)...which should get you 90% of the way. then following with either a file or sanding pads to sand down to the exact edge where you need.

power tools can be overkill for this and could destroy the tracks unless you know exactly what you’re doing and have extreme control/understanding of the tool.

Even then, plastic will melt under a tool with a high RPM and you could deform and ruin it without caution.

So again, use a fine toothed saw and it should be fine

Last edited:

Mouse Vader

Sr Member

there are 3D printed templates to help you match the angle for each track

It's really got that far ?!

It’s really gotten that “convenient”It's really got that far ?!

If you have the money

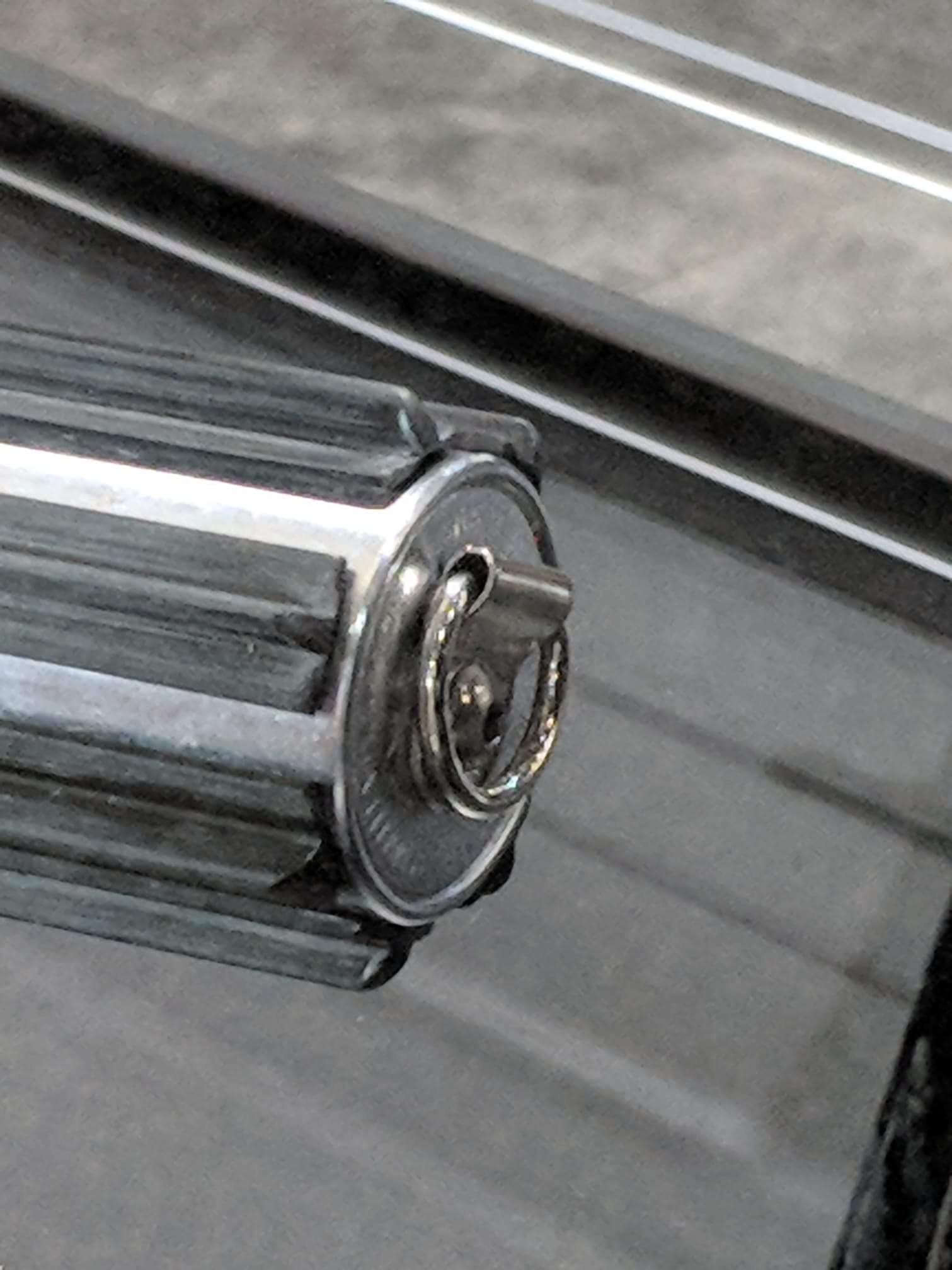

I would suggest that you mark a spot on top at around 3mm from the edge and then chop off the corner with a hand saw or a cutter. Then you can sand it smooth and round the corners a bit. Don't forget that the original was not machined! It was roughly cut by hand. The angle from one T-track to the next wasn't exactly 30 degrees. They just chopped off the corners probably to make it easier to the touch.

Roy (WannaWanga)

Roy (WannaWanga)

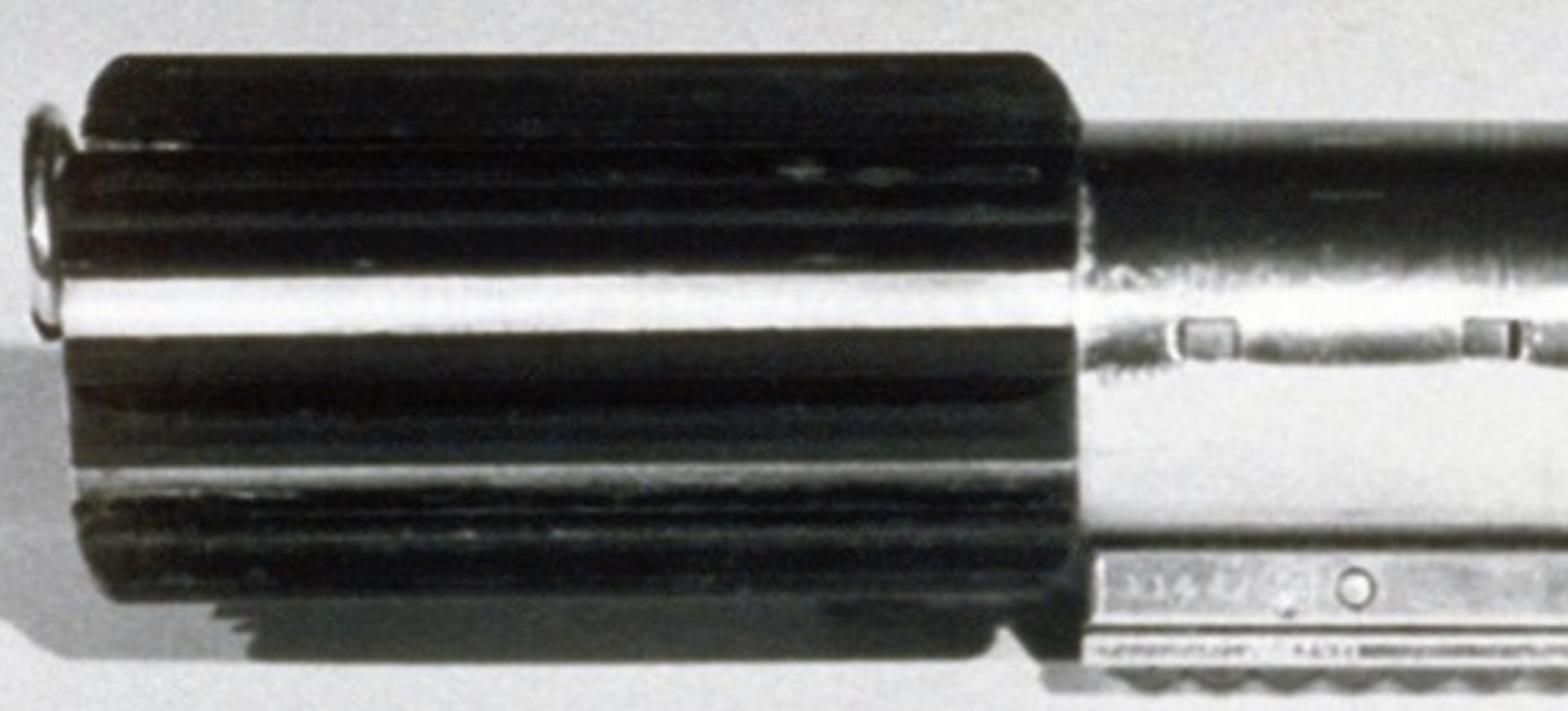

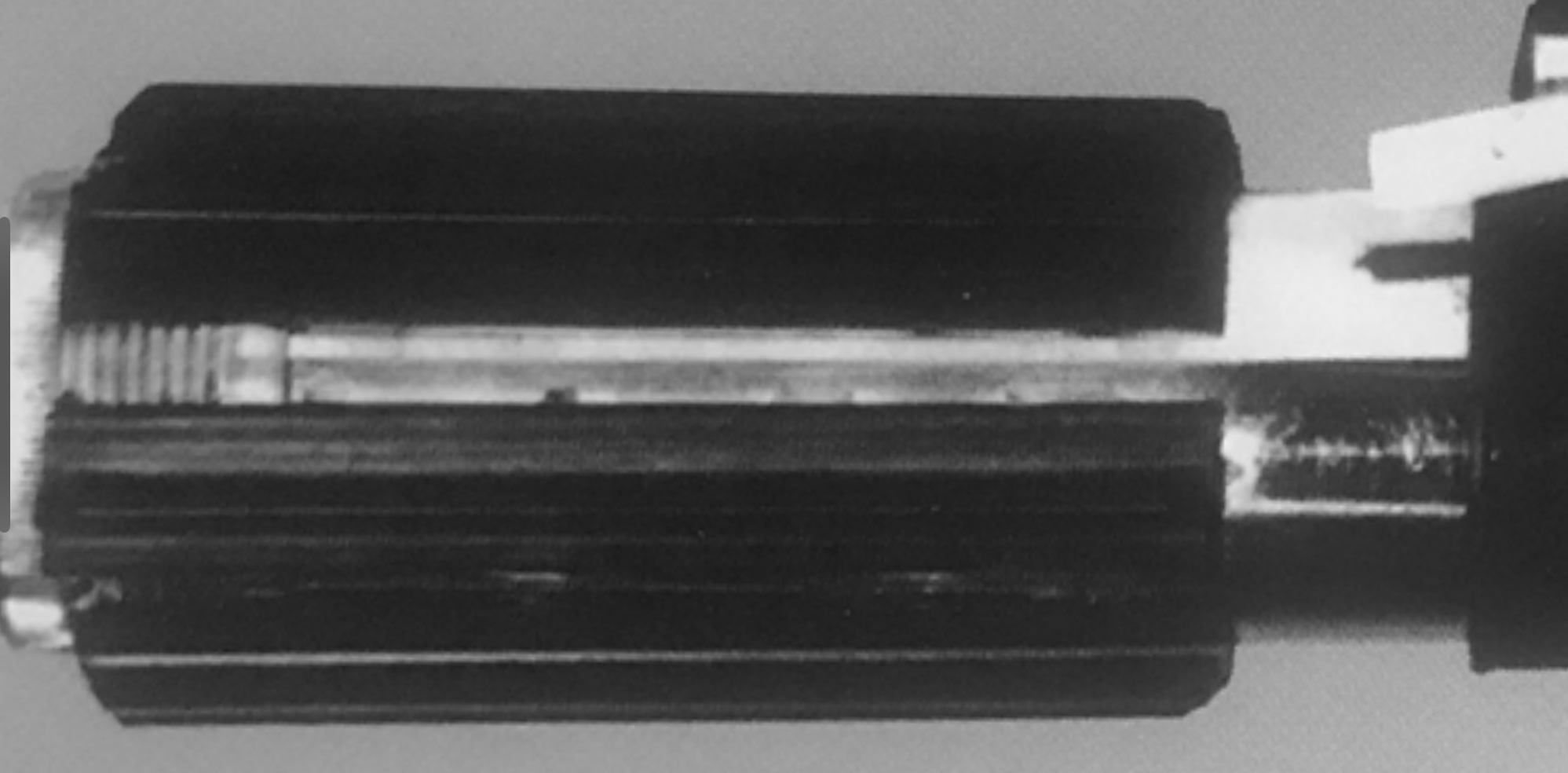

I personally subscribe to the “slightly rounded” vs. “sharply angled” look, myself...

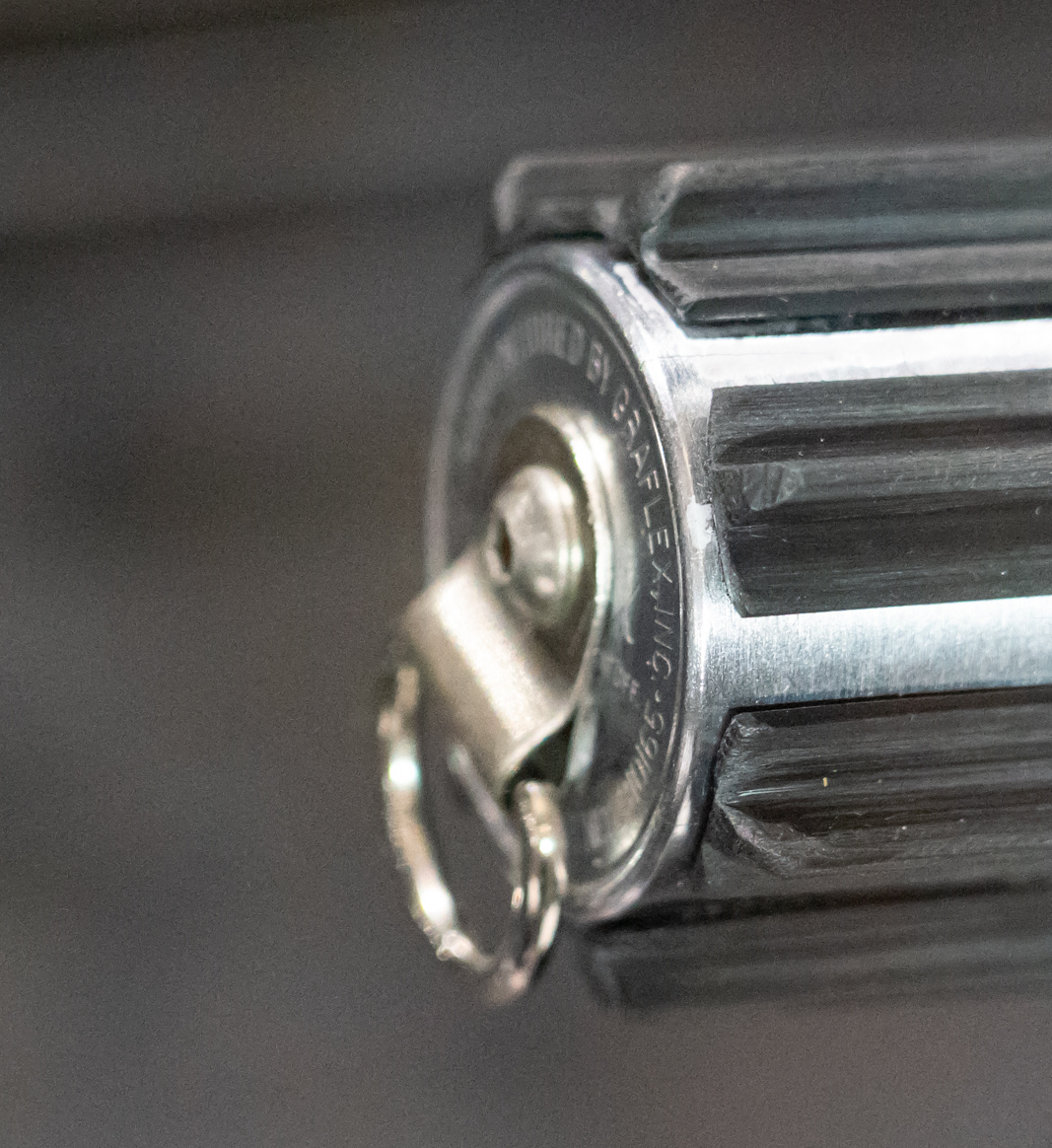

...but, as others have said, these things were hand made and all over the place, in terms of their look. If you do want that sharper angled look, there are some great 3D printed cutting templates available to make the job easier. Here’s one I picked up over at Shapeways for cutting the notches in Roy’s ESB grips that includes a template notch for cutting grip ends with a sharp angle.

...but, as others have said, these things were hand made and all over the place, in terms of their look. If you do want that sharper angled look, there are some great 3D printed cutting templates available to make the job easier. Here’s one I picked up over at Shapeways for cutting the notches in Roy’s ESB grips that includes a template notch for cutting grip ends with a sharp angle.

Last edited:

Mouse Vader

Sr Member

Here's the R.Christian 'original/fake' . As he made (or at least handled) the real thing I say it's about as good as you're gonna get.

After doing research I found and purchased one of these guides!I personally subscribe to the “slightly rounded” vs. “sharply angled” look, myself...

View attachment 1086565

View attachment 1086569

View attachment 1086570

View attachment 1086571

...but, as others have said, these things were hand made and all over the place, in terms of their look. If you do want that sharper angled look, there are some great 3D printed cutting templates available to make the job easier. Here’s one I picked up over for cutting the notches in Roy’s ESB grips that includes a template notch for cutting grip ends with a sharp angle.

View attachment 1086566

View attachment 1086567

View attachment 1086568

If I remember correctly, I think I noticed that the track were not all beveled the same. some were rounded, others more angular, and I can't imagine they're all exact 30 deg.

I actually use a medium metal file for the corners.

Yes exactly. Some are around 30 degrees some 45 degrees, some are more rounded. It's very uneven and just roughly done by hand.

Similar threads

- Replies

- 13

- Views

- 1,957

- Replies

- 25

- Views

- 4,254

- Replies

- 3

- Views

- 1,606

- Replies

- 17

- Views

- 2,765