Here's a little more of the work that I've done on the neck. This concentrates mostly on the shaft that runs underneath it.

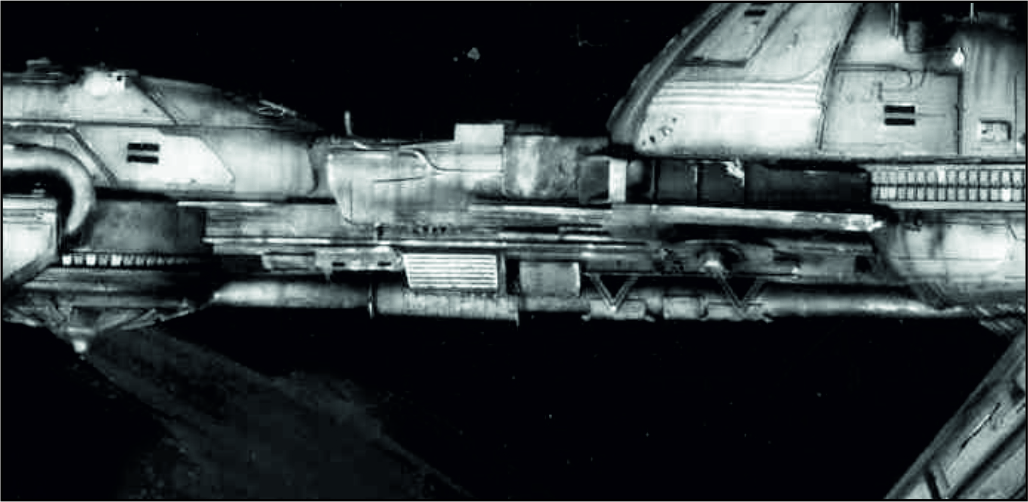

So, I already spent some time studying this area to get a feel for the elements that were needed, what I could make and what I could use from the kit and the Green Strawberry upgrades. I've already shared in an earlier post some of the details I'd a added to the GS resin shaft. Trouble was that after more study of the studio model I wasn't feeling very happy with the way everything looked in comparison.

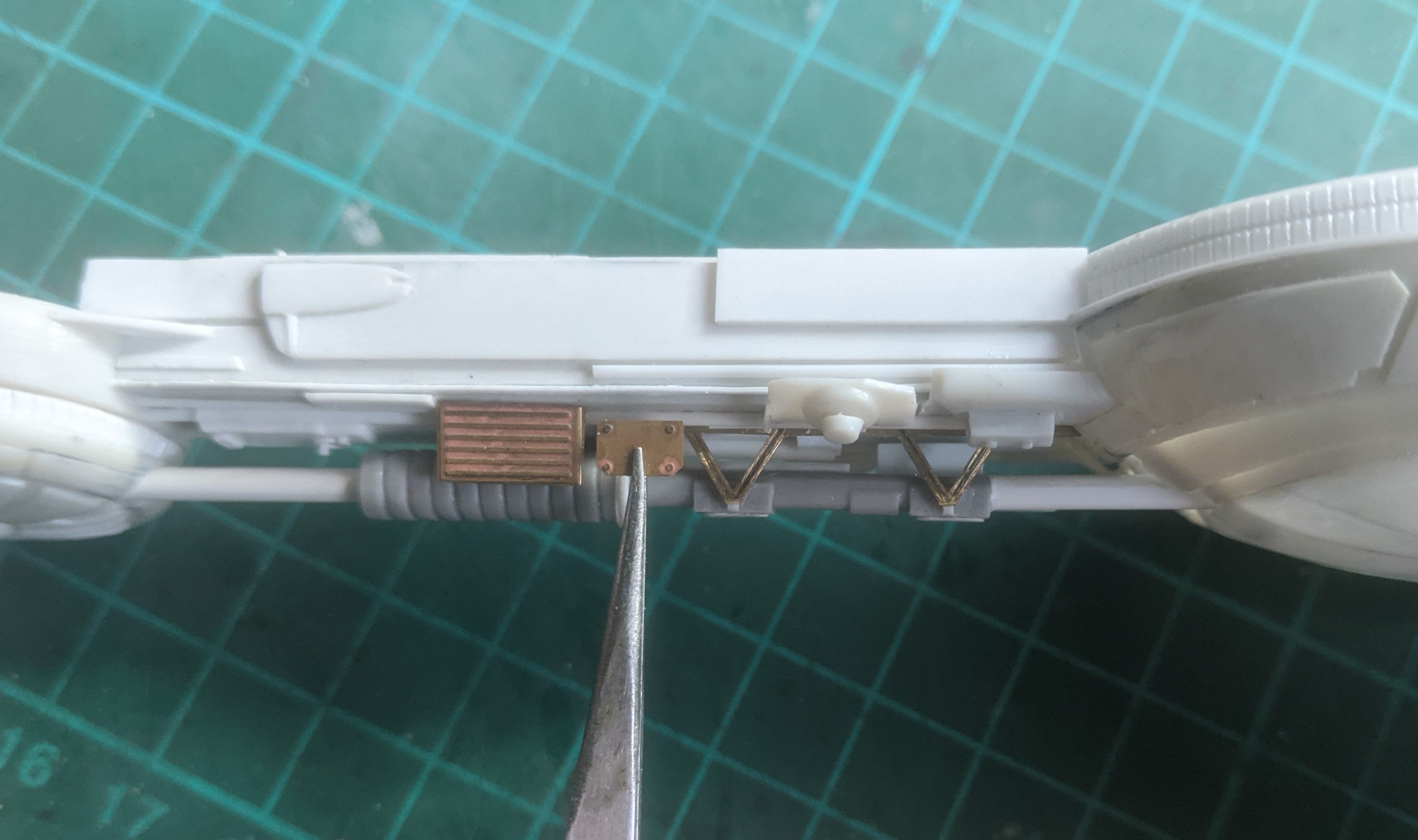

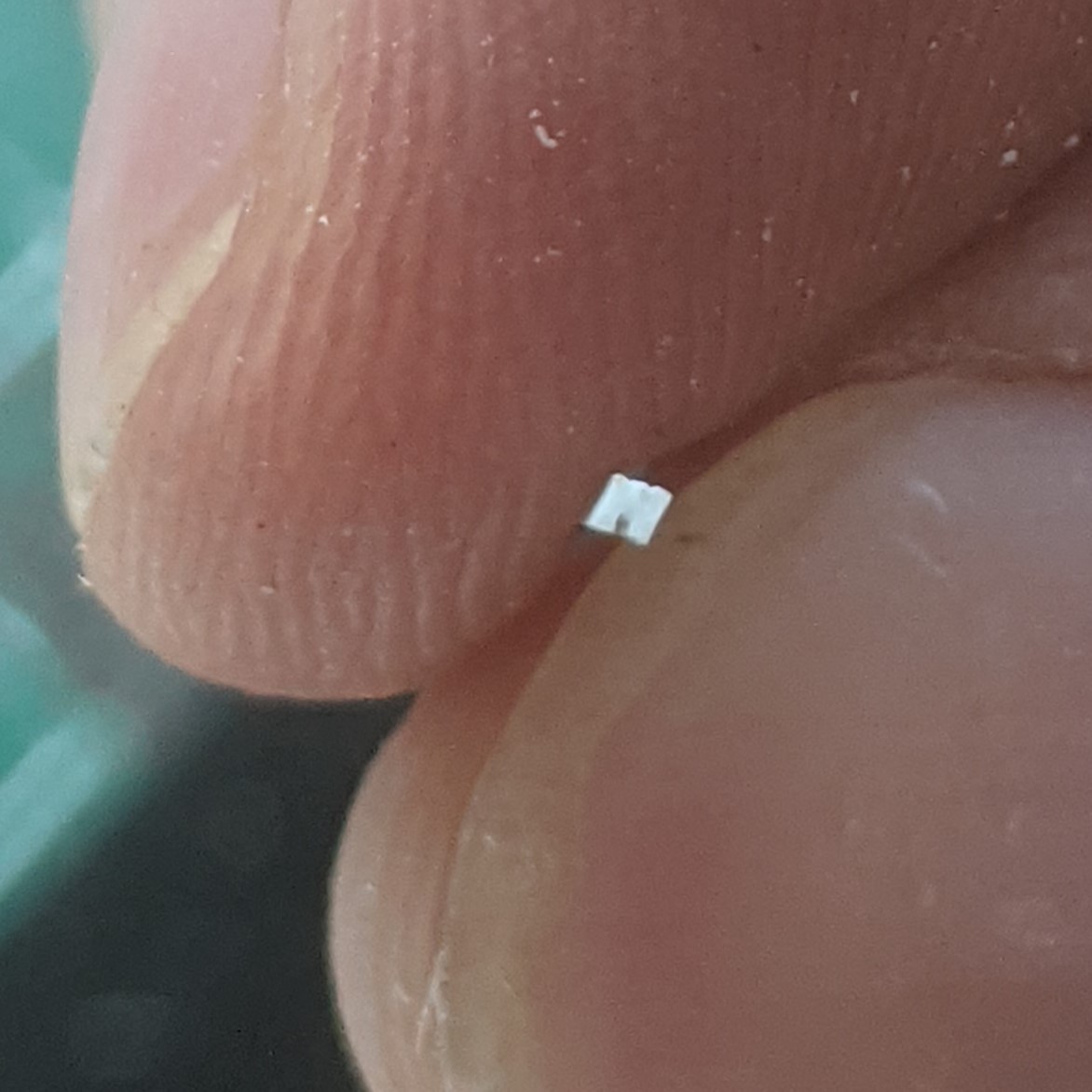

Things came to a head when I tried out one of the PE parts against the model. A small rectangular plate just behind the PE radiators under the neck.

According to the studio model it should sit in-between the wider cylinder of the shaft on the left and the 'V' shaped strut to its right. There wasn't enough room for it though.

Might not seem like too big a deal but this little test triggered a realisation that the proportions of the GS resin shaft weren't right.

The two 'V' struts are bigger than they should be and wider apart. The rectangular parts on the shaft that the V's points are connected to are too far apart. There are also some issues in my placement of the hanging radiator parts, I think I should have put these further forward rather than gluing in the same spot as the removed kit parts.

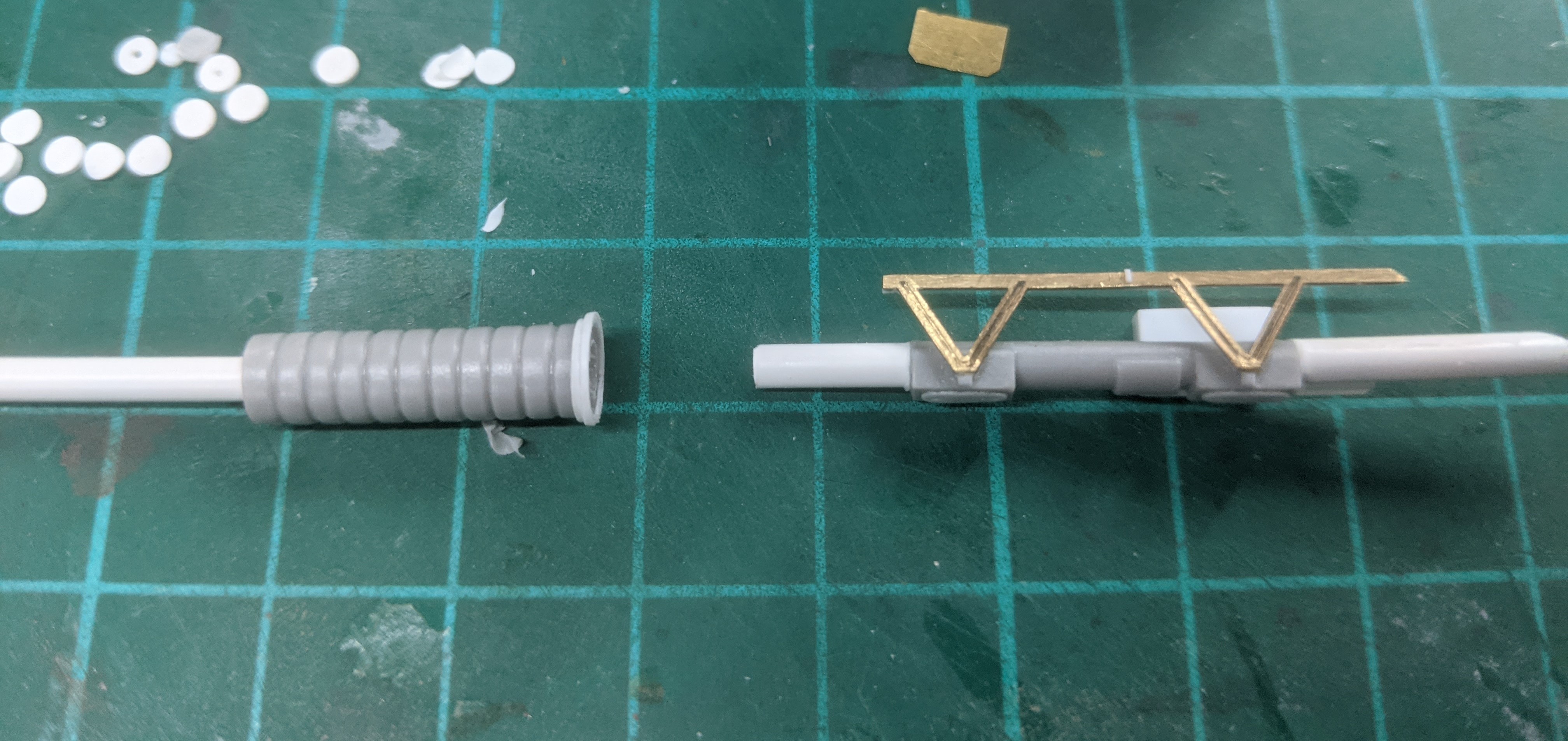

Initially I did try cutting up the shaft a bit more to widen the spot where that rectangular plate goes. But this just pushes those PE Vs further right and even more out of position. Here's my first try at putting it right anyways.

Cutting out the resin shaft.

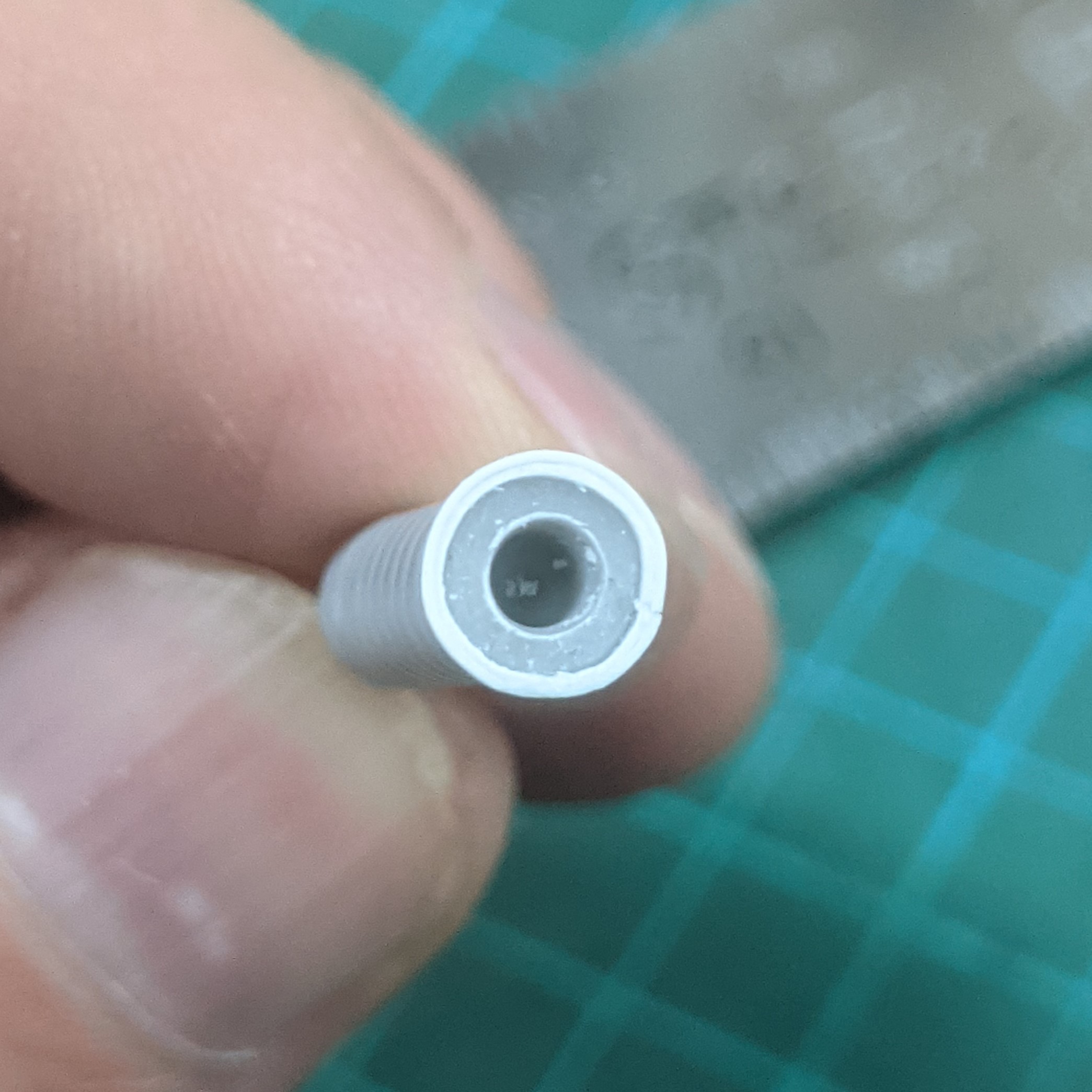

Drilling the larger cylinder to accept a 2.5mm styrene rod.

Gluing in a wider piece of styrene. All the white circles top left are my attempts to cut the end of the styrene rod nice and square.

All back together but still not happy as the Vs are no where near the correct position.

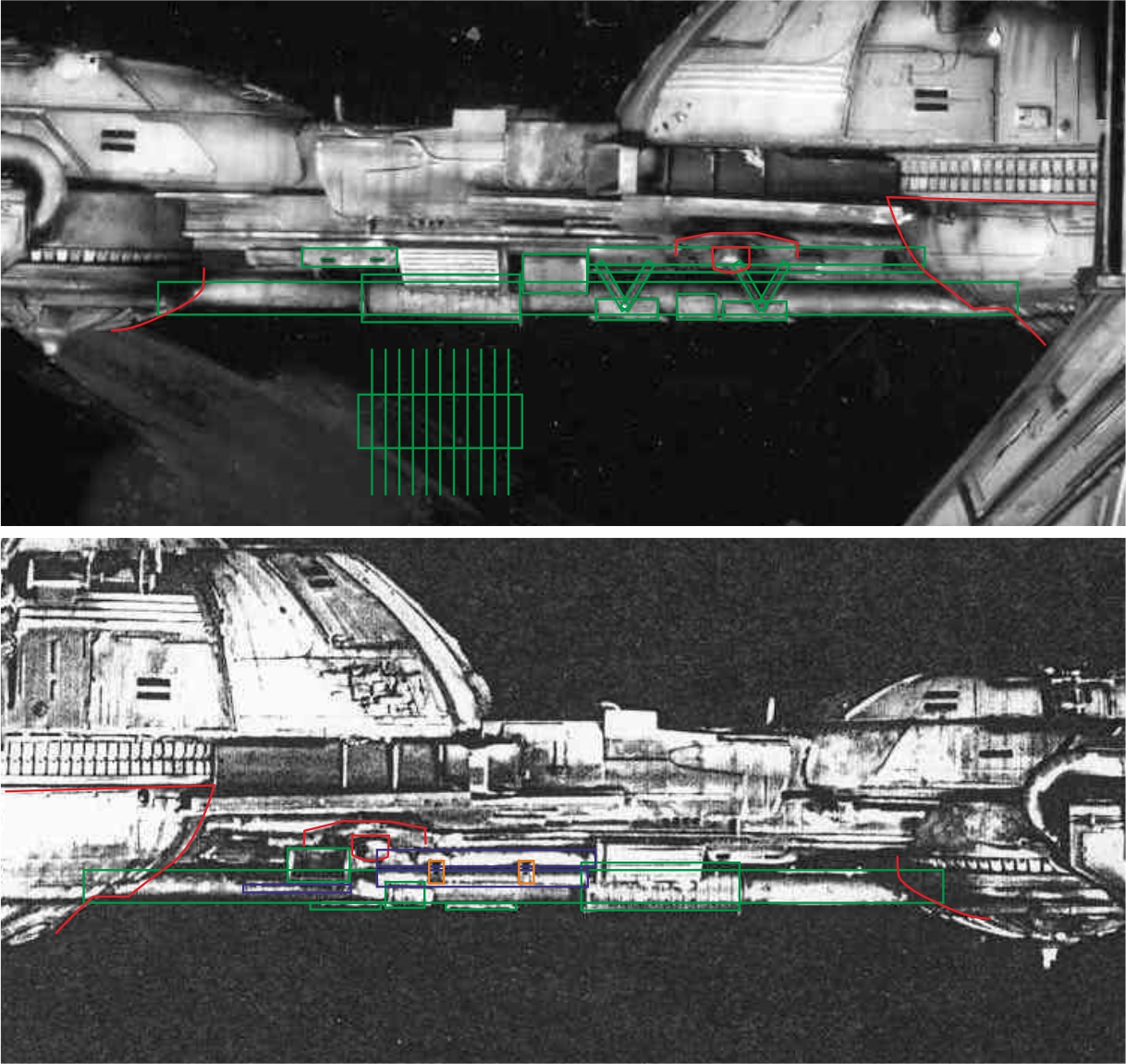

Okay, literally back to the drawing board. I opened the studio model pics on my computer, measured the length of the neck on my model kit, then sized the images so they were 1:1 scale. Next I drew over the top the various shapes I was going to try and replicate. Not everything will be in the right place on the kit as the radiator parts and the slotted pieces in front of them are too far aft. However I was prepared to let that go as the work to sort it did not balance with how minor a difference it is.

Here's the drawings I made. I then removed the image from the background and printed out the in scale line drawings to work against.

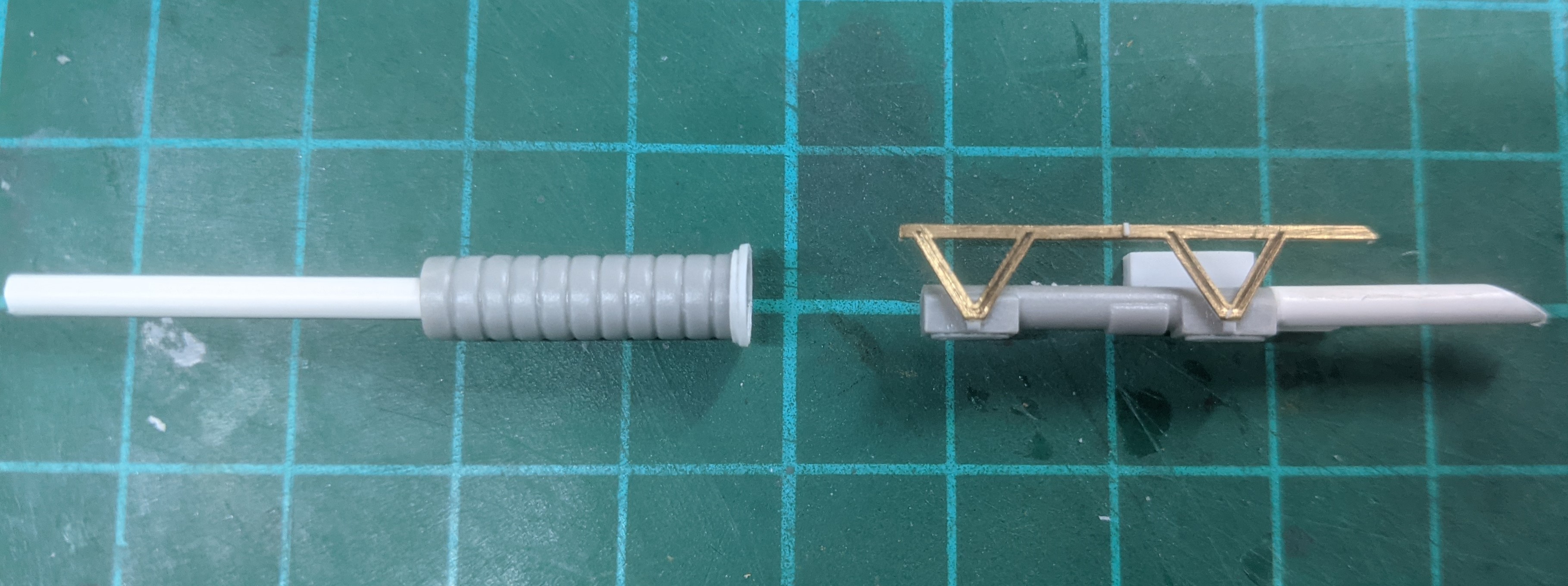

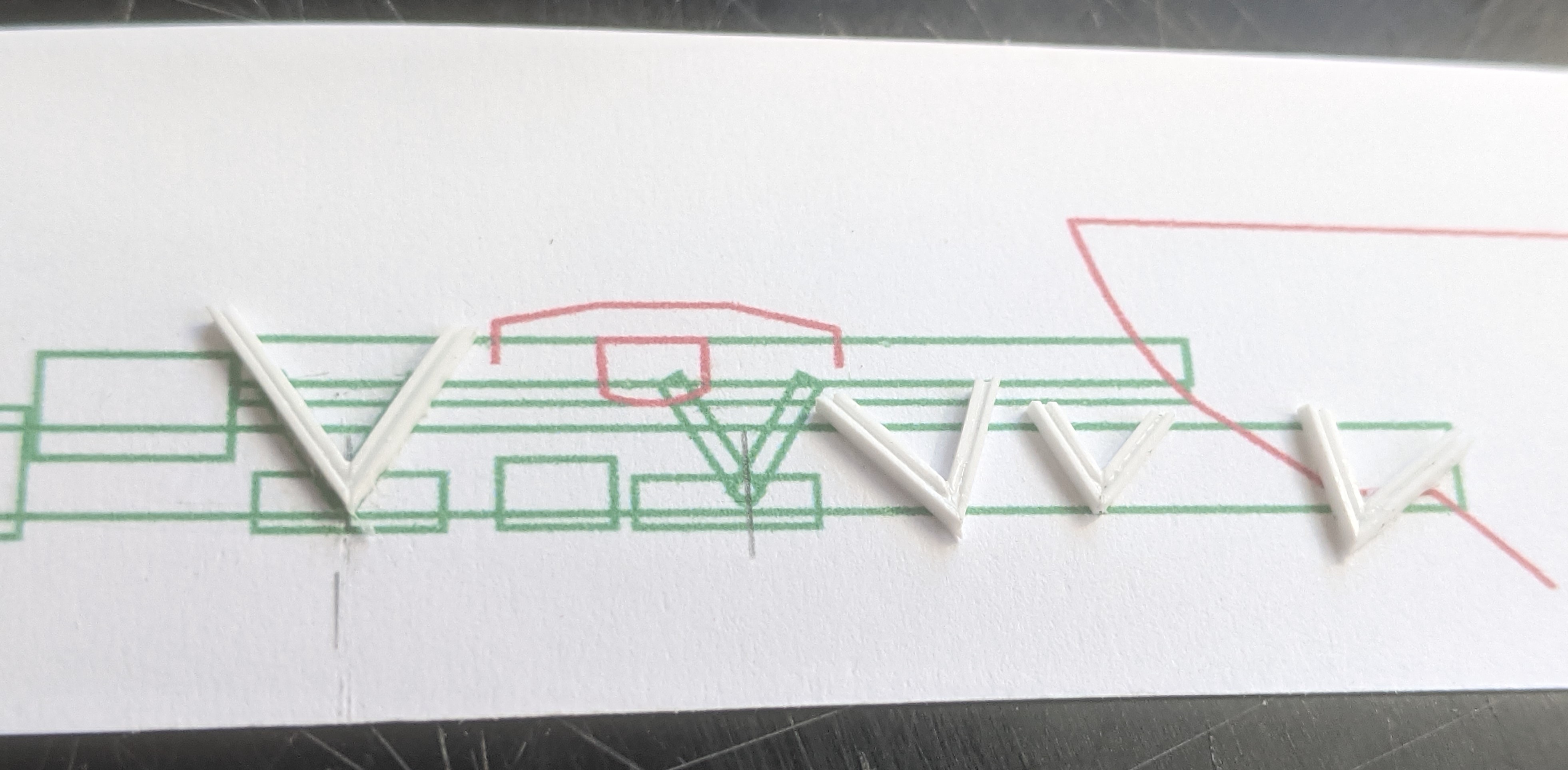

The first part I rebuilt was the double V struts. They have a U beam profile so to make this I laminated three thin strips together. One at 0.5mm x 0.25mm with a piece at 0.75mm x 0.25mm either side.

Here's a profile view to get a better idea.

These were next laid over the drawing, miter cut to the correct size with a razor blade before being glued together. They were then attached to the base part of the strut and detailed with some brackets I could see in one of the ref pics.

I'll pick this up again in the next post.

So, I already spent some time studying this area to get a feel for the elements that were needed, what I could make and what I could use from the kit and the Green Strawberry upgrades. I've already shared in an earlier post some of the details I'd a added to the GS resin shaft. Trouble was that after more study of the studio model I wasn't feeling very happy with the way everything looked in comparison.

Things came to a head when I tried out one of the PE parts against the model. A small rectangular plate just behind the PE radiators under the neck.

According to the studio model it should sit in-between the wider cylinder of the shaft on the left and the 'V' shaped strut to its right. There wasn't enough room for it though.

Might not seem like too big a deal but this little test triggered a realisation that the proportions of the GS resin shaft weren't right.

The two 'V' struts are bigger than they should be and wider apart. The rectangular parts on the shaft that the V's points are connected to are too far apart. There are also some issues in my placement of the hanging radiator parts, I think I should have put these further forward rather than gluing in the same spot as the removed kit parts.

Initially I did try cutting up the shaft a bit more to widen the spot where that rectangular plate goes. But this just pushes those PE Vs further right and even more out of position. Here's my first try at putting it right anyways.

Cutting out the resin shaft.

Drilling the larger cylinder to accept a 2.5mm styrene rod.

Gluing in a wider piece of styrene. All the white circles top left are my attempts to cut the end of the styrene rod nice and square.

All back together but still not happy as the Vs are no where near the correct position.

Okay, literally back to the drawing board. I opened the studio model pics on my computer, measured the length of the neck on my model kit, then sized the images so they were 1:1 scale. Next I drew over the top the various shapes I was going to try and replicate. Not everything will be in the right place on the kit as the radiator parts and the slotted pieces in front of them are too far aft. However I was prepared to let that go as the work to sort it did not balance with how minor a difference it is.

Here's the drawings I made. I then removed the image from the background and printed out the in scale line drawings to work against.

The first part I rebuilt was the double V struts. They have a U beam profile so to make this I laminated three thin strips together. One at 0.5mm x 0.25mm with a piece at 0.75mm x 0.25mm either side.

Here's a profile view to get a better idea.

These were next laid over the drawing, miter cut to the correct size with a razor blade before being glued together. They were then attached to the base part of the strut and detailed with some brackets I could see in one of the ref pics.

I'll pick this up again in the next post.