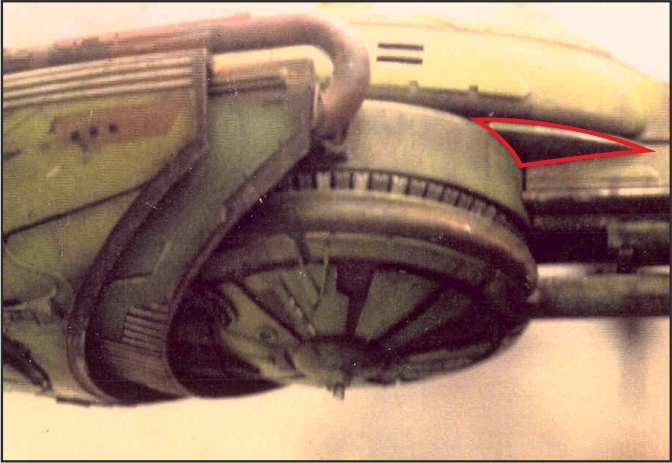

Next up I replaced the curved brace parts that sit under the rear overhanging part of the upper bridge.

I'd ended up cutting these off to make it easier to build up the base structure of the neck.

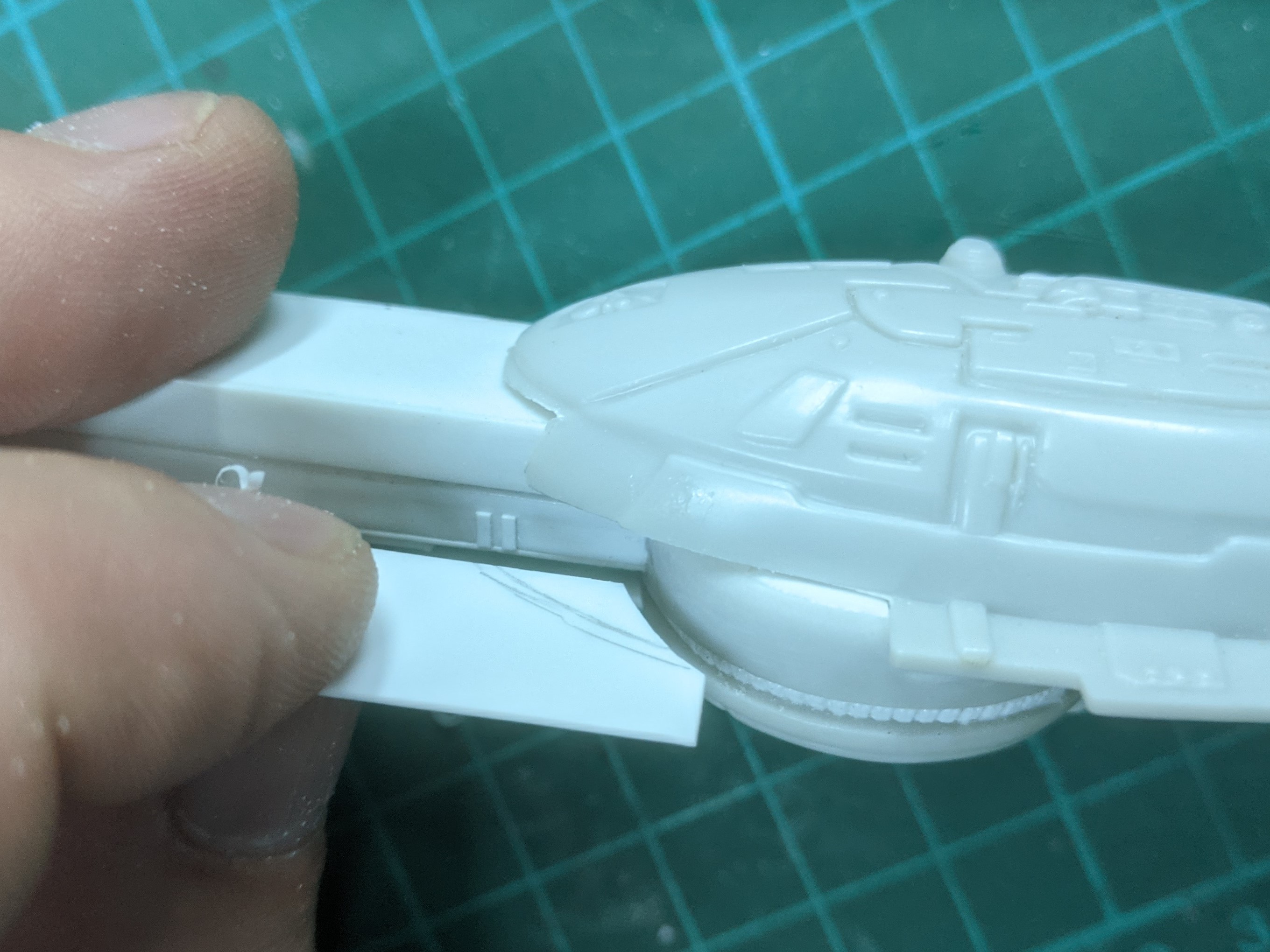

Firstly I held a piece of 0.5mm styrene sheet up against the model to mark the outline I needed. Here I've already cut the shape to fit against the curve of the lower bridge.

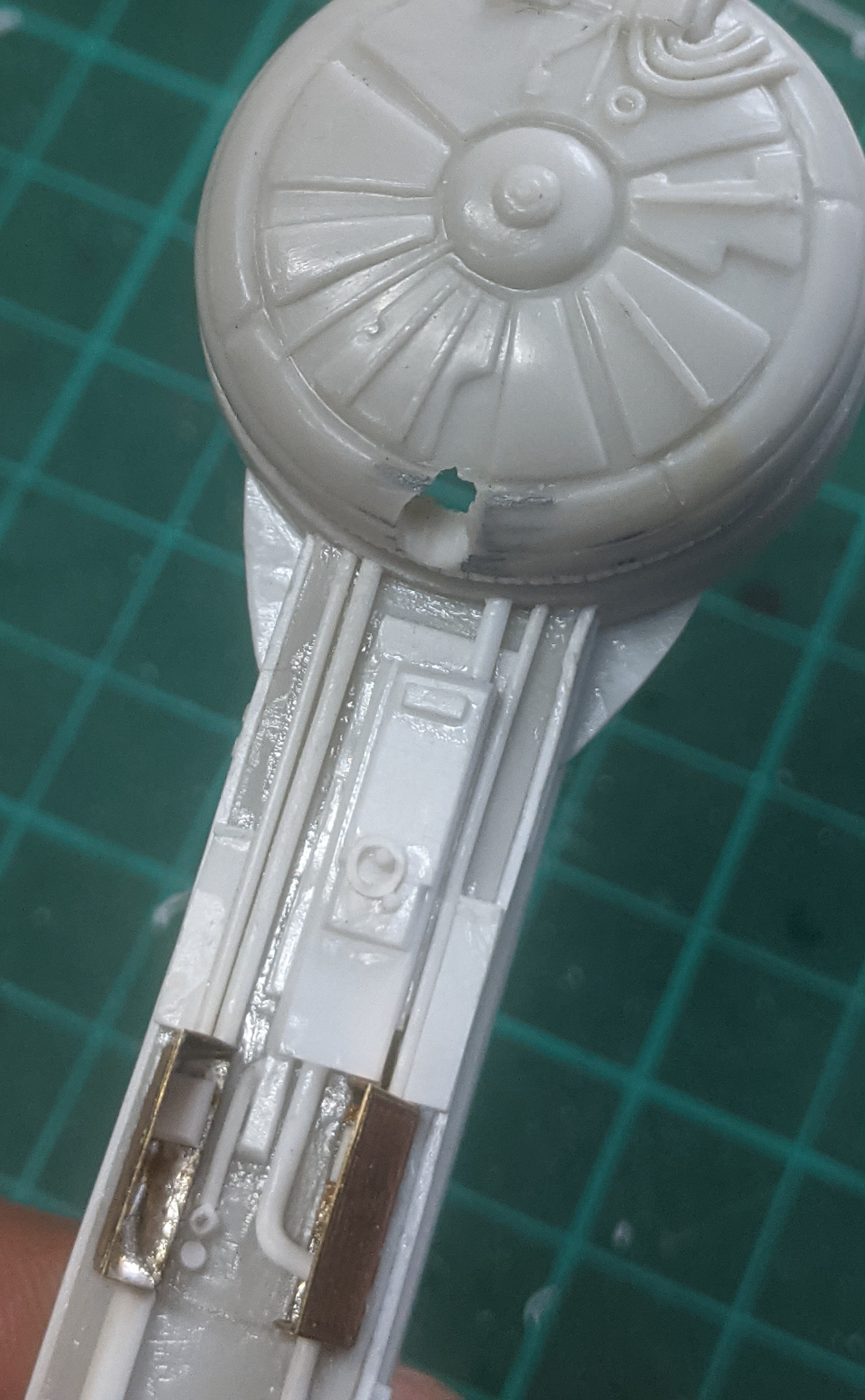

Both sides were cut, had the edges smoothed with a fine grit sandpaper and then were glued in place against the neck.

You can also see above where I've added some more detail to the underside of the neck. I wouldn't claim this to be accurate, it is the best I can do with the images I have plus artistic license to fill bare areas.

I'd ended up cutting these off to make it easier to build up the base structure of the neck.

Firstly I held a piece of 0.5mm styrene sheet up against the model to mark the outline I needed. Here I've already cut the shape to fit against the curve of the lower bridge.

Both sides were cut, had the edges smoothed with a fine grit sandpaper and then were glued in place against the neck.

You can also see above where I've added some more detail to the underside of the neck. I wouldn't claim this to be accurate, it is the best I can do with the images I have plus artistic license to fill bare areas.