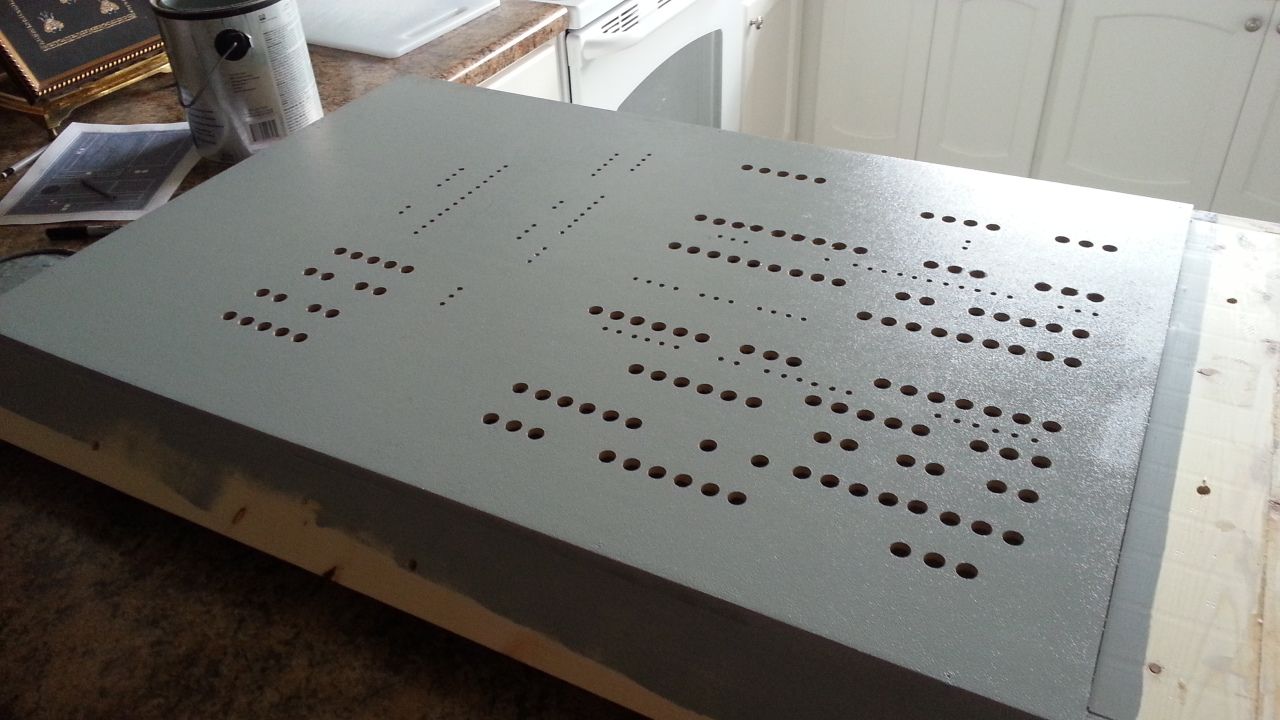

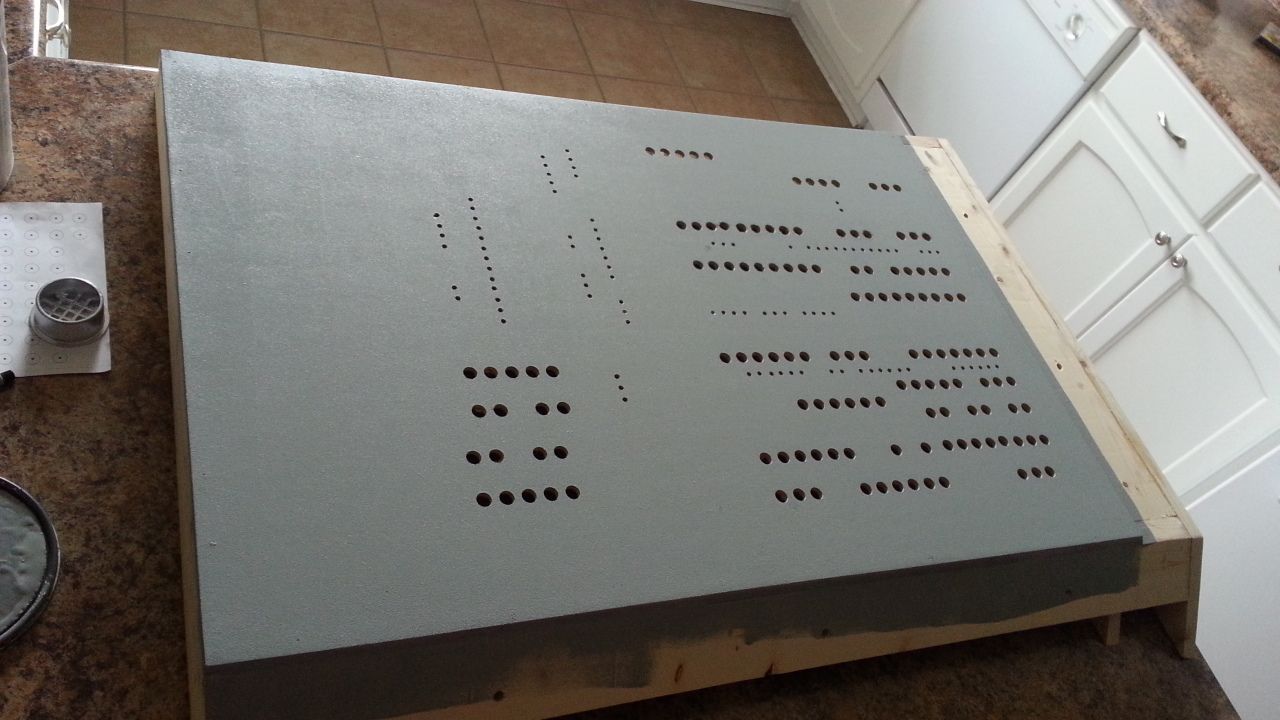

Re: 1:1 Millennium Falcon Console Replica

I agree, that was a great article.

I agree, that was a great article.

I enjoid the articleAnother article re: the build!

http://www.tennessean.com/apps/pbcs.dll/article?AID=2012312210127

Enjoy!

I'm trying my hand at making molds of all the buttons...

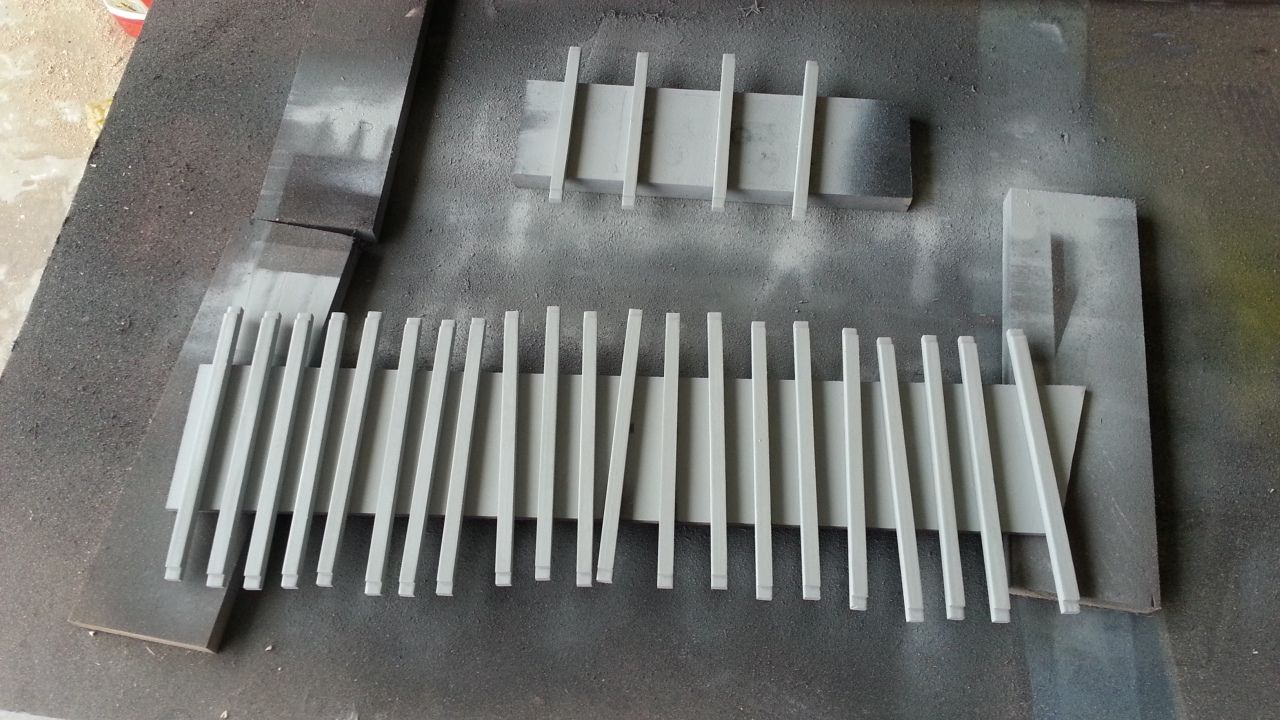

Wouldn't it be easier and cheaper to cut angles on a long board to get the shape right, then cut them to width?

The switches were wood in "real life ". I agree they definitely do look like wood and not even just close up. So probably not ideal for this project.

Molds would work but only if you want to cast 100 + or whatever it is. I would get them cut from something less grainy than wood.

So here's a question. And not to derail, but...

Things like the cockpit, guns, and such are exciting and immediately gratifying to make. Who's working on the rest of the ship?

This cockpit build inspires me but I still find it hard to fathom that the full ship will ever be built. Have full plans been made and checked by an engineer? How many people are working on the project?

Don't want to sound like a downer. I REALLY want this to happen.

If you head over to The Full Scale Millennium Falcon Project and browse through the forum, and the site, you'll see that work has begun on the 88 acre site. I am in talks with an archtitect now who will hopefully be able to take Starkillers 3D model and convert them to a working blueprint that will include all dimensions, HVAC, load bearing tolerances, etc...

Yep... One can assume it will take time to figure it all out. The hollow wood shell of the original set piece was heavy enough in it's own right, but once you start talking about adding innards, covering it in steel, and making sure it's safe (electrically, ventilation-wise, lighting-wise, load bearing-wise, etc.), it gets complicated. Plus, one can only hope that the city / township won't have a problem with it, and that all of the necessary permits will be obtained. My hat is off to you guys. Wishing Chris and the rest of you all the best on getting it worked out.

I did that with the console rockers and it was VERY time consuming. The process from cutting, sanding, priming, painting tooks almost a week. Also, no rocker looked the same. If I make molds, it not only saves time but each rocker will be identical.

Hey bud, did you stop using the Formica and now just treating and priming the wood? I can't tell from the pics?