TitaniumBat

Sr Member

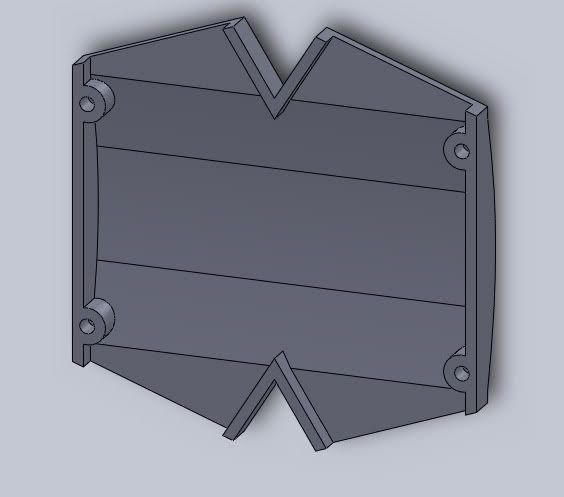

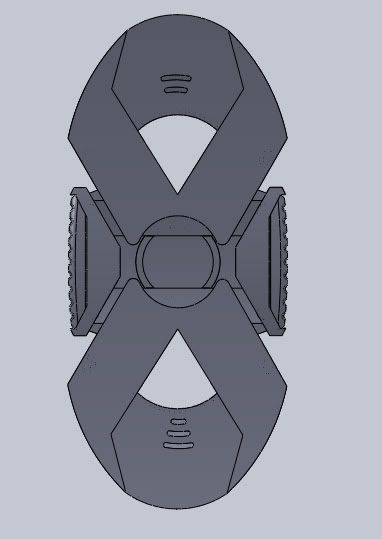

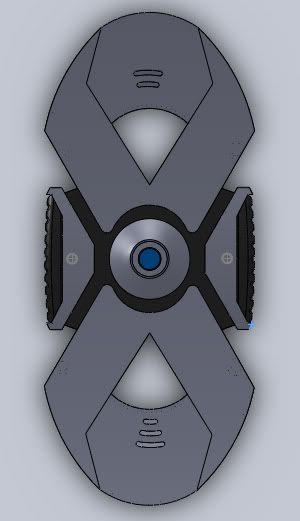

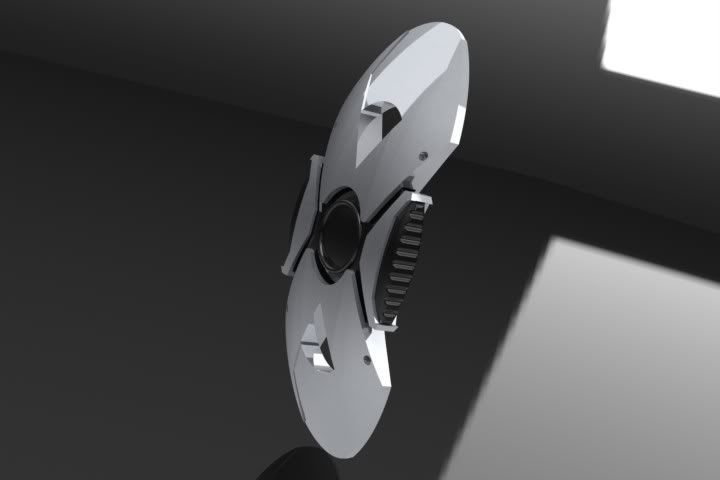

Nice job superDrool :thumbsup That was similar to what I was thinking although your design in better. I had the latches split in half with the horizontal spring in the middle. Your design has fewer parts and it ensures they work together at the same time. The only thing I didn't see is a stop that prevents the two halves from flying completley off, this could easily be added to the back.

Jay - Based on the model I have I would say just "squish" it down as it needs to be shorter and a little wider. I completely agree with SD regarding the bluetooth device it should be easy to fit. As for the on/off switch I was thinking it could be added by the horizontal spring. That way when you open the phone it would turn on plus it would add resistance to keep the button pushed out. When you end the call just press the button again, then you can manually slide the X peices down.

I'm really looking forward to this ... GREAT Job guys!!

Jay - Based on the model I have I would say just "squish" it down as it needs to be shorter and a little wider. I completely agree with SD regarding the bluetooth device it should be easy to fit. As for the on/off switch I was thinking it could be added by the horizontal spring. That way when you open the phone it would turn on plus it would add resistance to keep the button pushed out. When you end the call just press the button again, then you can manually slide the X peices down.

I'm really looking forward to this ... GREAT Job guys!!