hi..

my two cents here (and it differs a bit from others before me.. so take it with a grain of salt)

"I" personally 'did' go with a HarborFreight lathe.. why? well for the machine I got.. the price I got it for was UNBEATABLE!.. (by anyone, anywhere)

I got word that the HF 8x12 (which is really an 8x14, same exact machine as the lathe master 8x14 but in red and different tooling package).. for $449..

I walked in "with" a 20% off coupon.. and ordered up my 8x lathe for $379 out the door.

waited a few weeks until it came into stock.. and went a happy camper.

My suggestions are KNOW what you want to work on, wnat you intend to use these lathes for...

you will find yourself running out of room before you know it if you dont plan ahead.

having never owned a lathe previously,. in my head these was going to be HUGE..

and I had never seen an 7x in person before either..

I stopped back a week later to HF to get something else.. and they had a 7x10 lathe on the floor... and man that thing is RINKY DINKY.. IMHO.. not much bigger than two shoe boxes tall.. and maybe1-2 in length..

with the 10" bed.... and the chuck and tail stock eating up most of the room.. you can only turn something that is around 6in or so.. (give or take)

the 8x lathe I got was still a HOBBY machine... but its MUCH more heavy/beefier.. but still a size that is manageable...

I made a 2ft x 4ft table for my lathe and it has room all around..and room for a box with my sprays some tools..etc..

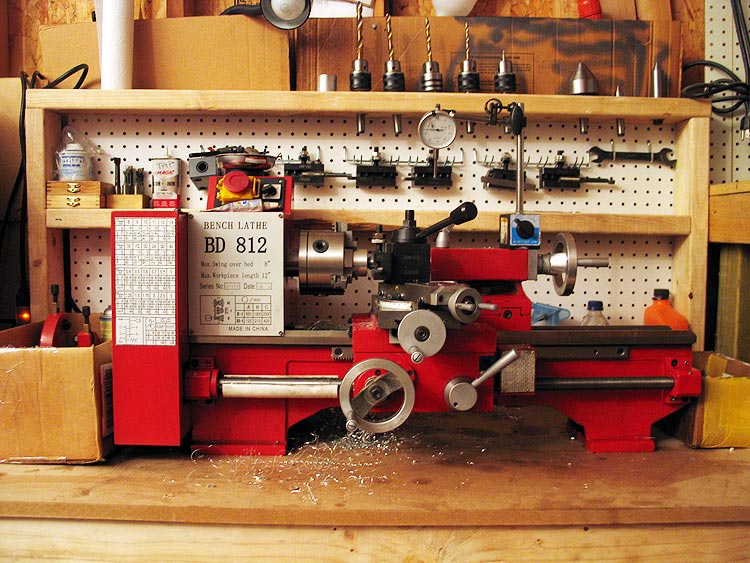

actually here it is:

and here a picture of a 7x10 lathe sitting on top of an 8x lathe..

just so you have a visual in your mind.

(If you plan on doing saber hilts.. I would recommend AGAINST the 7x10 size, at a minimum the 7x12 size)

As far as HF vs other places.. to be fair.. 'most' of these chinese/imported lathes are the same. different color or brand stamped on it for whomever is selling it... maybe a different tooling package..or minor upgrade done here or there..etc.. but or the most part.. all the same.

You will need to spend time on any choice, taking it apart, cleaning it, oiling/lubing and putting it back together... so you make the call on your time vs money.

One exception "I" have found is LittleMachineShop.. most of their machines come with a better fit-n-finish then most others I have seen..

If you get a good deal/sale and can also use a coupon.. I think an HF purchase is OK.. especially if you are DIY/HOBBY minded.

I also own a mill.... I purchased this one from LittleMachienShop.com though.. (Hi-Torque, mini-mill..etc)..

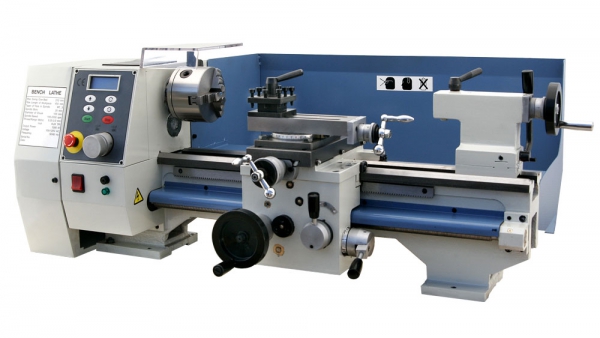

here is on I own:

https://www.littlemachineshop.com/3960

if I could have afforded an X3 sized mill.. I woudl gotten one.. biggest mill you can afford and have space for is my advice on mills.

I had saw the HF X2 mini-mill on sale for like $399.. but missed out on it....(I still have coupon I think) lol..

but got the SX2 from LMS....

LMS is NOT cheap.. (matter fact almost always more expensive than anyone else).. but I have not found better customer service from ANY company.... regardless of product!!!!.. and knowledgeable too!

and when I compared the X2 features..(and upgrades I would have done.. belt drive..etc) compared to the SX2 features....(which has better motor, comes with belt drive, bigger table size, more travel..etc) the prices were 'too' far apart.. and LMS machine was ready to go out of box more or less)..

I would advise AGAINST the TWO-in-one machines lathe/mill combos.. or at least remove the mill head, get a new base like many other people have done with those combo machines..

in the end.. I am 'for' anyone getting a lathe/mill.. learning is fun.. and you'll soon find yourself fixing or making parts for others things too (I made some aluminum bushings/spacers for my lawnmower....fixed my snowblower sheared cotter pin..etc)

NOTE: expect to spend as much (if not more) on tooling for your machine, than the cost of the machine itself!!!!

Safety is a must, they are dangerous and powerful machines, but can be fun when respected!..

good luck!