You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The PEPAKURA question thread - PLEASE READ RULES IN FIRST POST!

- Thread starter DaddyfromNaboo

- Start date

-

- Tags

- star wars

The Ronin

Well-Known Member

http://www.therpf.com/f24/pepakura-question-thread-please-read-rules-first-87056/#post1246506Just a noob question; How do I properly scale something? I'm building a foam Iron Man and have seen many builders have to restart their builds because the scaling was off.

Look through the tutorials in the first post for most of your answers. There are some amazing tuts over at the 405th

Pepakura and Cardboard Armor

Otherwise, it can be a bit of trial and error sometimes. Not much you can do about that. I've built multiple forearms and thighs for my halo armor because I'm just a bit oddly sized and the tutorial calculations just don't fit my body shape. I had to make the thighs a bit oversized because my legs are very muscular (I used to do leg presses in excess of 1000lbs) and even though they were the right length, they wouldn't fit around the middle of my thigh.

Last edited:

Chaotic Descent

New Member

What makes a spot annoying?Amen to this. It's amazing how much easier you can make something just by unfolding it properly. I swear some of the unfolds I've seen look like some monkey just started clicking on random places, hoping it would work. Before I print anything out, I make sure to go over it in pep designer VERY thoroughly to look for annoying spots that can make what should be an easy job into a difficult one.

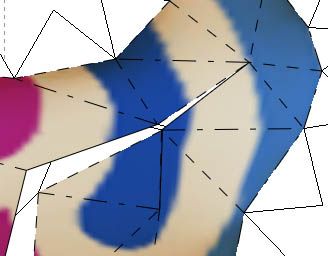

Do they connect some parts together that then make other parts meant to connect together not have enough room for tabs? (attached picture example.) How much of a problem is that?

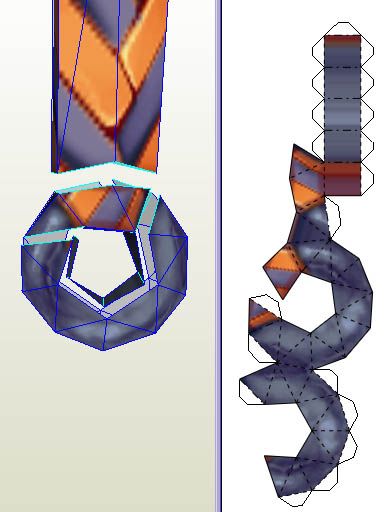

Also, what about a shape like this?

I bet some general guidelines could be made for different patterns of 3D models.

I guess people prefer spending more time gluing, so that they can make sure things line up or something?

elro

Active Member

Green - You probably want those tabs. Especially the sharpest point - Why isnt it cut to the edge that is right near by???

Blue - This line will be a problem getting into shape, especillay considering the paper is getting squeezed into the shape very the green.

Pink = THE BIGGEST PROBLEM. This part is overlapping inside itself. This is impossible to build accurately.

, Do you have the PEP file you can send me so I can unfold it so you can study it and hopefully go and learn something?

Blue - This line will be a problem getting into shape, especillay considering the paper is getting squeezed into the shape very the green.

Pink = THE BIGGEST PROBLEM. This part is overlapping inside itself. This is impossible to build accurately.

, Do you have the PEP file you can send me so I can unfold it so you can study it and hopefully go and learn something?

The Ronin

Well-Known Member

The problems I've seen the most are where a really complex or tight fold will happen and the unfold is just so wonky that it's nearly impossible to make a clean pep. The HD thighs for Mk.VI Halo armor are notorious for this.What makes a spot annoying?

Do they connect some parts together that then make other parts meant to connect together not have enough room for tabs? (attached picture example.) How much of a problem is that?

I sure do. A few more pieces to make sure something is accurate and even is worth the extra time to me.I guess people prefer spending more time gluing, so that they can make sure things line up or something?

BlackKaos

Sr Member

Not sure if this has been mentioned on this thread but has anyone tried using joint compound (Dry wall puddy)? I know that it's very easy to sand but not that strong. It would cut sanding time way down because it's so easy to sand. I've heard that it gets stronger when painted. Any feedback would be greatly appreciated.

Pilot

Sr Member

Here's MightyJohn's post from a couple of years ago (in a different thread) about using drywall compound instead of Bondo. I keep that link around, as the question does pop up occasionally.

AlienTemplar

New Member

Is there any way to get unfolded versions on a mac without having to install windows via bootcamp? :confused

THankS!

Pepviewer and editor both work fine in OSX. Just ensure you have wine installed.

Sent from my Kindle Fire using Tapatalk 2

The crazy gnu

New Member

Sorry guys, new here but, what website do I use to insert pics of my foam builds in here, got a few builds to share and start questions with... Gman

The crazy gnu

New Member

Blakkous I used drywall patch to fill holes in my foam armor works good so far, but u hafta prime it before your finished coat...

RaDDersMaDDness

Active Member

still looking for Thor vest foam pep file...

has anyone seen or attempted this yet?

has anyone seen or attempted this yet?

Kaotik

Active Member

Re: still looking for Thor vest foam pep file...

Do you mean his armour?

you can find it here: Pepakura Gallery

Kaotik

Do you mean his armour?

you can find it here: Pepakura Gallery

Kaotik

Deelite

Active Member

Sorry guys, new here but, what website do I use to insert pics of my foam builds in here, got a few builds to share and start questions with... Gman

when you hit reply, you can add in your own pics at the bottom of the reply box "Manage Attachements"

Otherwise

photobucket

imageshack

flickr

bobafettsslave1

Active Member

Iron man mk 4 back flaps

Hi All,

I am looking for mk 4 pepakura back flaps. Can you help please.

:thumbsup

Hi All,

I am looking for mk 4 pepakura back flaps. Can you help please.

:thumbsup

RaDDersMaDDness

Active Member

Re: still looking for Thor vest foam pep file...

wow, thanks, Ive been looking for something like this forever lol, so my next question is how do you get someone to convert the file for foam?

wow, thanks, Ive been looking for something like this forever lol, so my next question is how do you get someone to convert the file for foam?

Kurtis876

Well-Known Member

hello everyone,

this is mostly directed at anyone experienced in pepping/fiberglass/resin-ing... I watch some old Stealth videos on youtube, and am trying to understand something correctly. Is it possible to "resin" a pepped file (in cardstock, for example) with smooth-on smoothcast 320/321 and simply do a few layers inside and out, bondo/rondo/sand it, and have something that is fairly strong? that is, can one basically use the smooth cast in place of resin, but get away with NO fiberglass reinforcement?

I suppose I'm trying to find a way to have a durable/rigid suit without getting into fiberglass. I've been experimenting in foam and sintra, but foam seems a tad under-rigid+possible paint creasing...and sintra seems great at first until you discover how relatively easy it is to crack or break it.

if you feel it would be more appropriate for me to begin a thread in a different category, would you mind directing me to a good area?

Thanks very much for any help! :thumbsup

this is mostly directed at anyone experienced in pepping/fiberglass/resin-ing... I watch some old Stealth videos on youtube, and am trying to understand something correctly. Is it possible to "resin" a pepped file (in cardstock, for example) with smooth-on smoothcast 320/321 and simply do a few layers inside and out, bondo/rondo/sand it, and have something that is fairly strong? that is, can one basically use the smooth cast in place of resin, but get away with NO fiberglass reinforcement?

I suppose I'm trying to find a way to have a durable/rigid suit without getting into fiberglass. I've been experimenting in foam and sintra, but foam seems a tad under-rigid+possible paint creasing...and sintra seems great at first until you discover how relatively easy it is to crack or break it.

if you feel it would be more appropriate for me to begin a thread in a different category, would you mind directing me to a good area?

Thanks very much for any help! :thumbsup

Similar threads

- Replies

- 3

- Views

- 444

- Replies

- 0

- Views

- 152