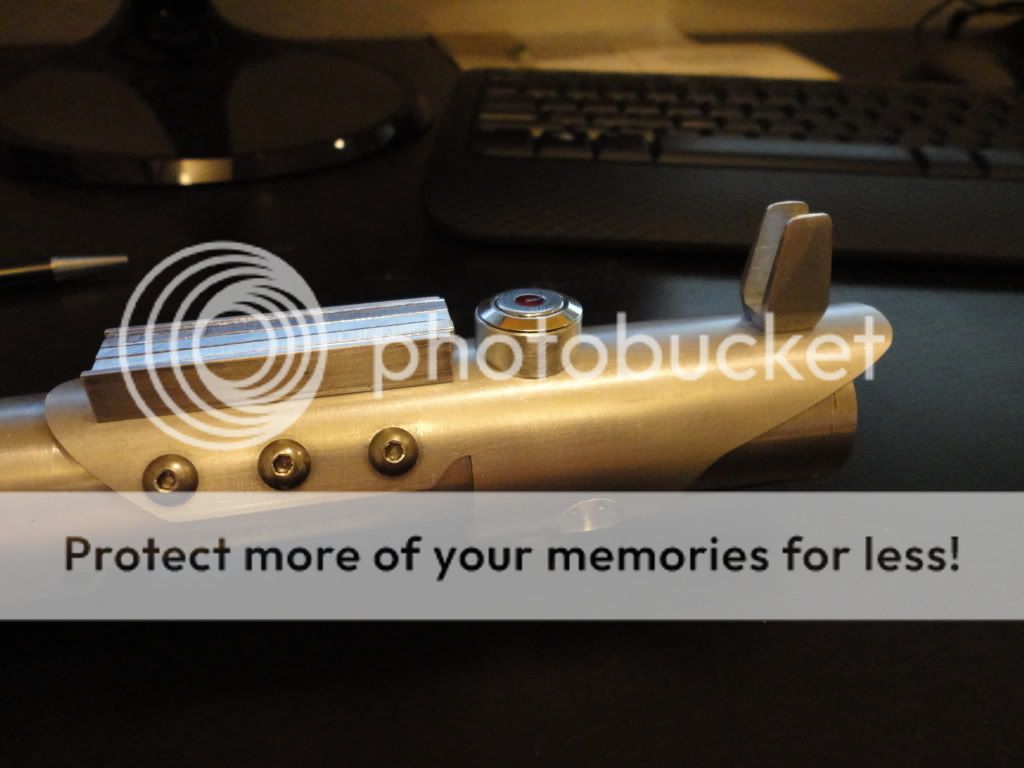

Lichtbringer

Master Member

I really like your build. :cool

wow, i love to know how to work metal

Aye, indeed a outstanding fine build. :thumbsup