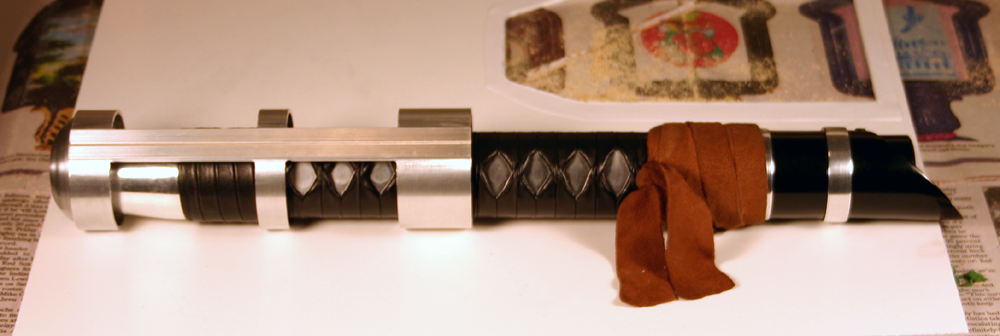

Re: Rahm Kota TFU2 - WIP

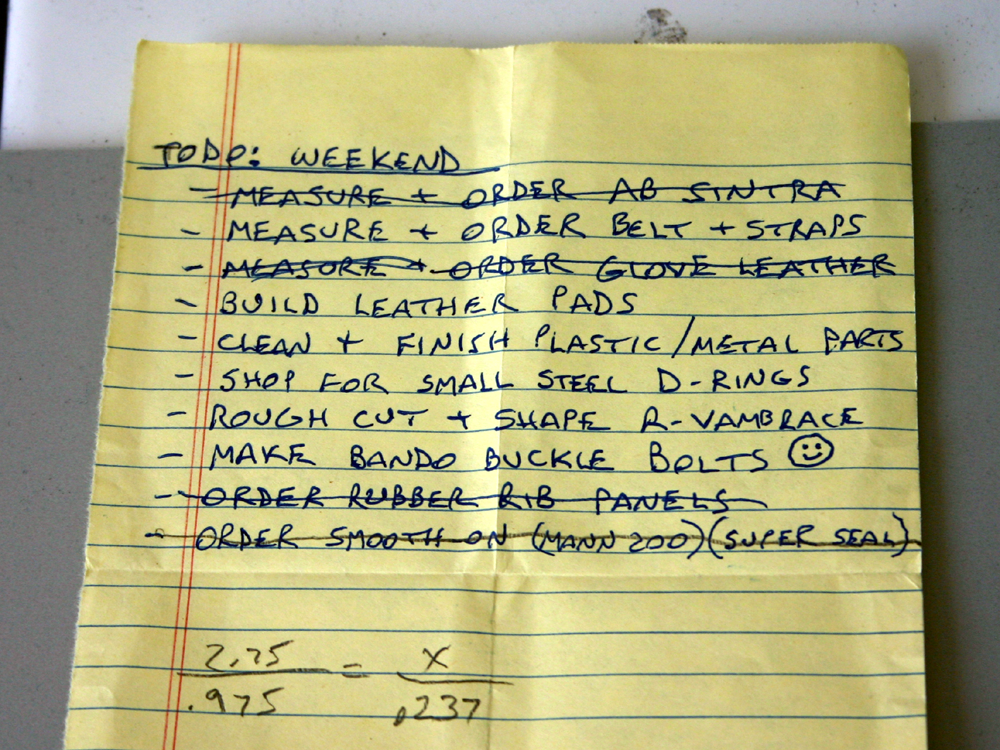

Some random thoughts on this stage of the project:

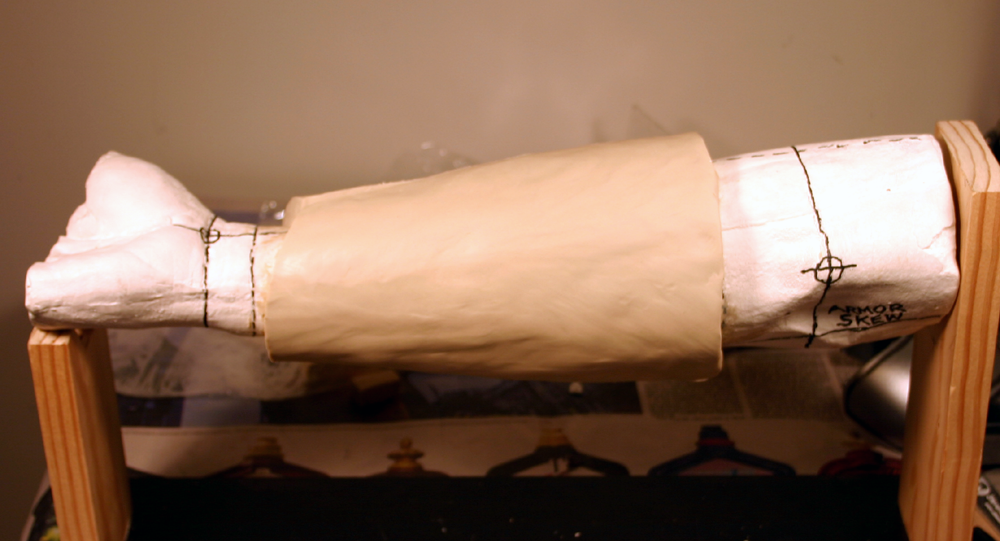

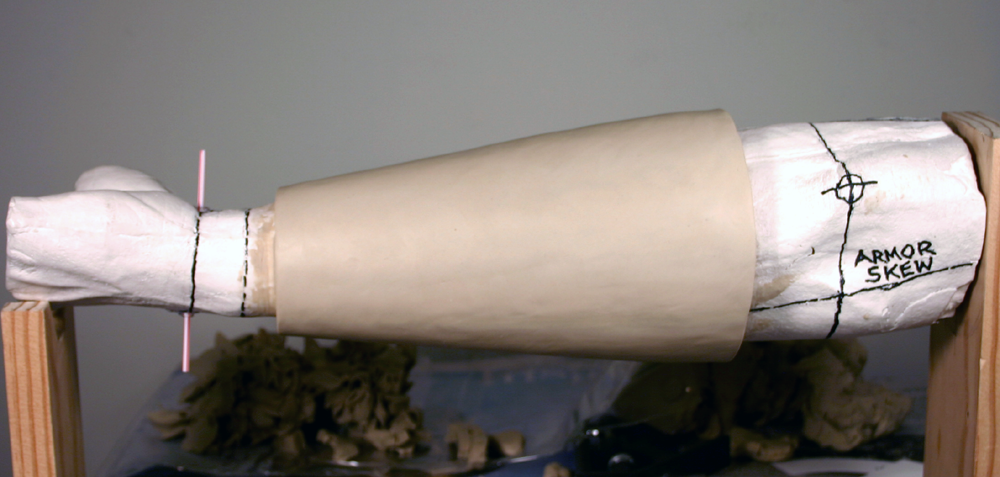

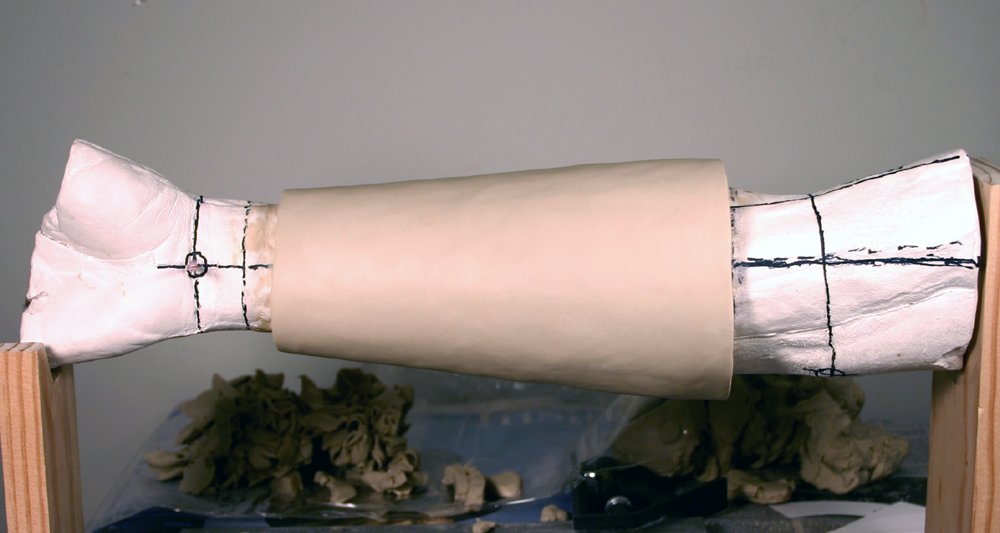

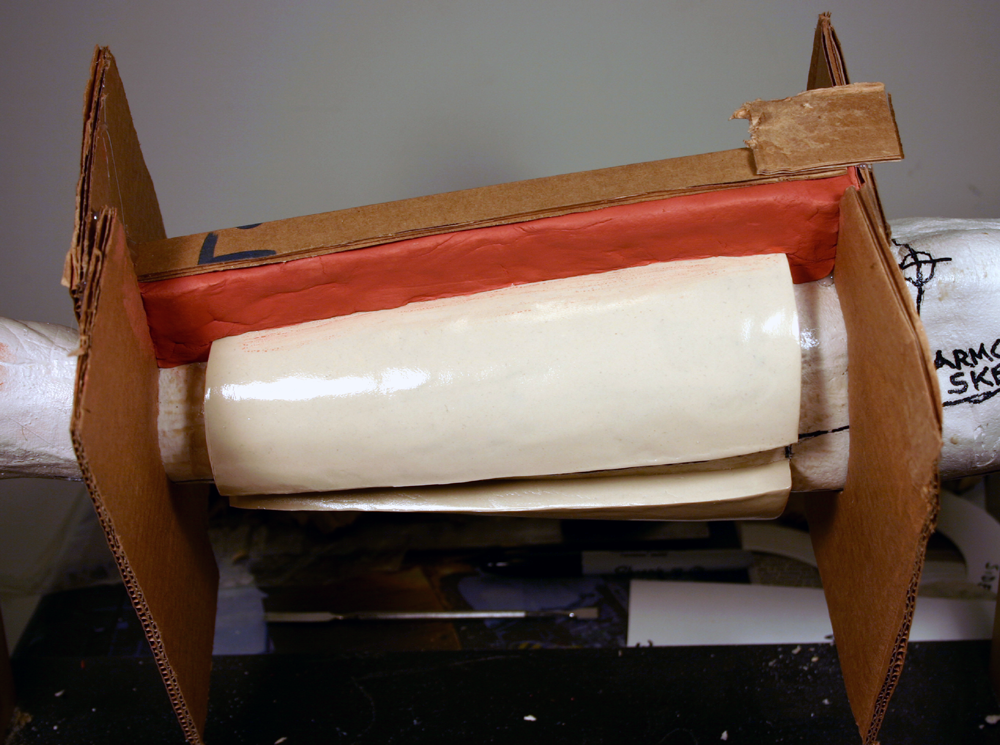

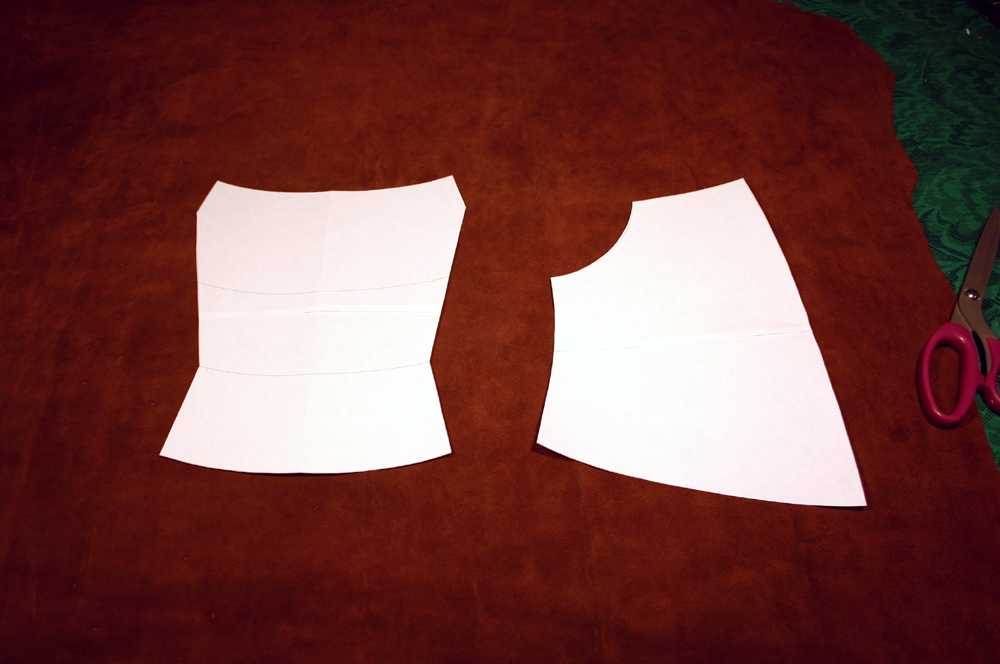

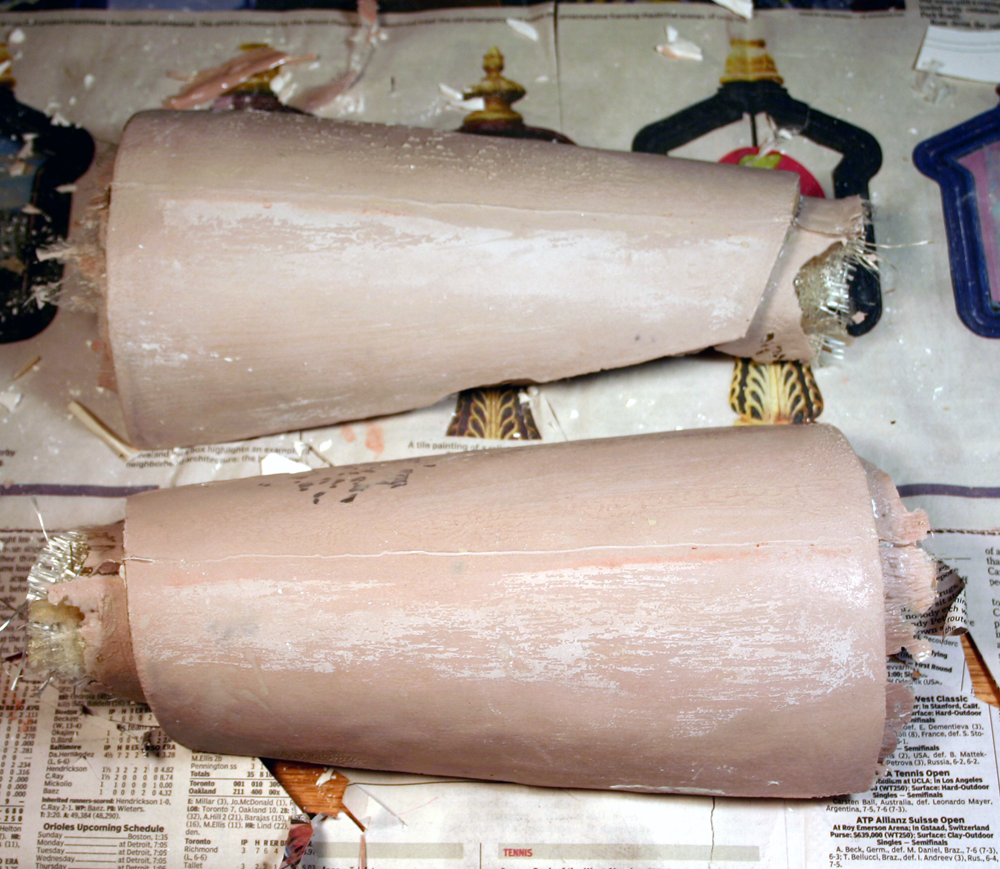

Up to this point, the armor pieces that have been built have been caps of a sort. The shoulders and handguards kind of just sit on or stand off of their respective body parts. The arms are the first to "wrap around" a body part. These and the torso armor have to leave some space between the plastic and the skin. If they don't, then the costume wearer (in this case, me) won't be able to move or breathe.

For the arms (and torso as well), I gave a lot of thought to several factors. First and foremost, the finished elements need to look like the game renders. Secondly, they need to look like the game renders while the wearer is moving. Third, the wearer needs to be able to move, preferrably the way the CG model moves or as close to that as possible. Lastly, the armor should not present any health hazards to the wearer for the duration of the 'cosplay' (used in its most literal definition).

I had some concerns that numbers one and two above might suffer for the other requirements (I still have some for the torso, but more on that later).

The CG game model armor elements have the luxury of being flexible along any axis. They can twist, stretch and contract as the body twists, stretches and contracts. The live armor parts cannot. This requires study of body motion for the part in question. For the arms, that means bending at the elbow and twisting at the wrist. It means paying attention to the limitations of the rigid part while wearing the armor. The key is knowing how far to limit the range of motion of the body. As the elbow bends, for example, it will reach a point beyond which if the rigid element is built to accommodate such a motion range, accuracy will fall below acceptable limits set by the costume crafter. On the other hand, preserving 100% accuracy may very well limit range of motion to a point where acceptable human functionality suffers.

It's finding the balance point between these two factors that's the trick.

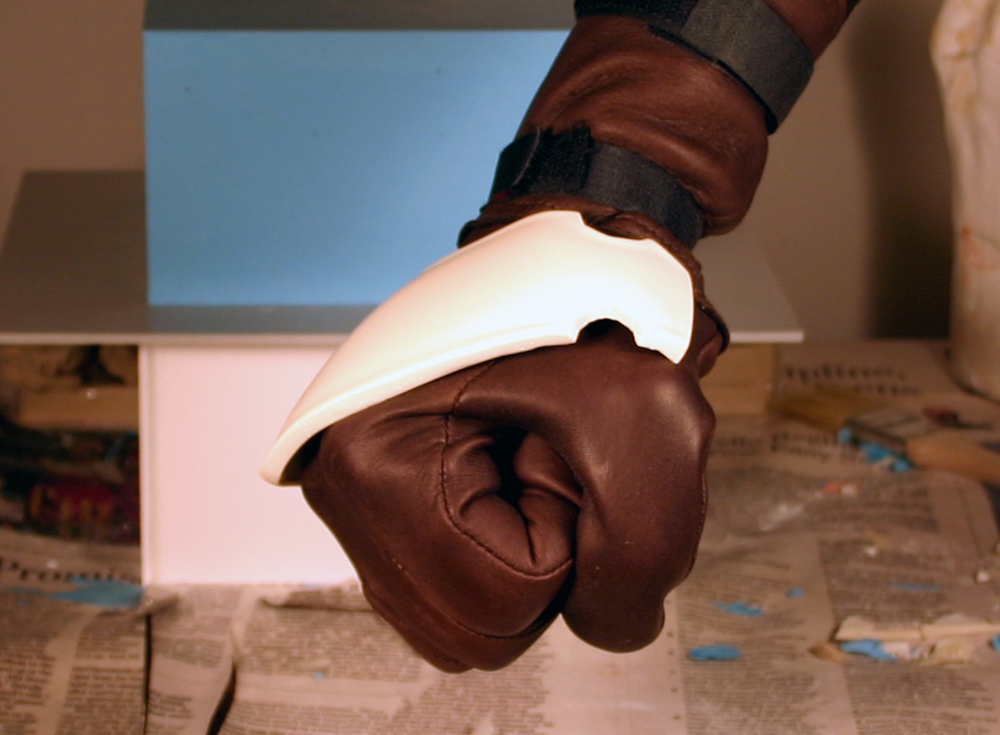

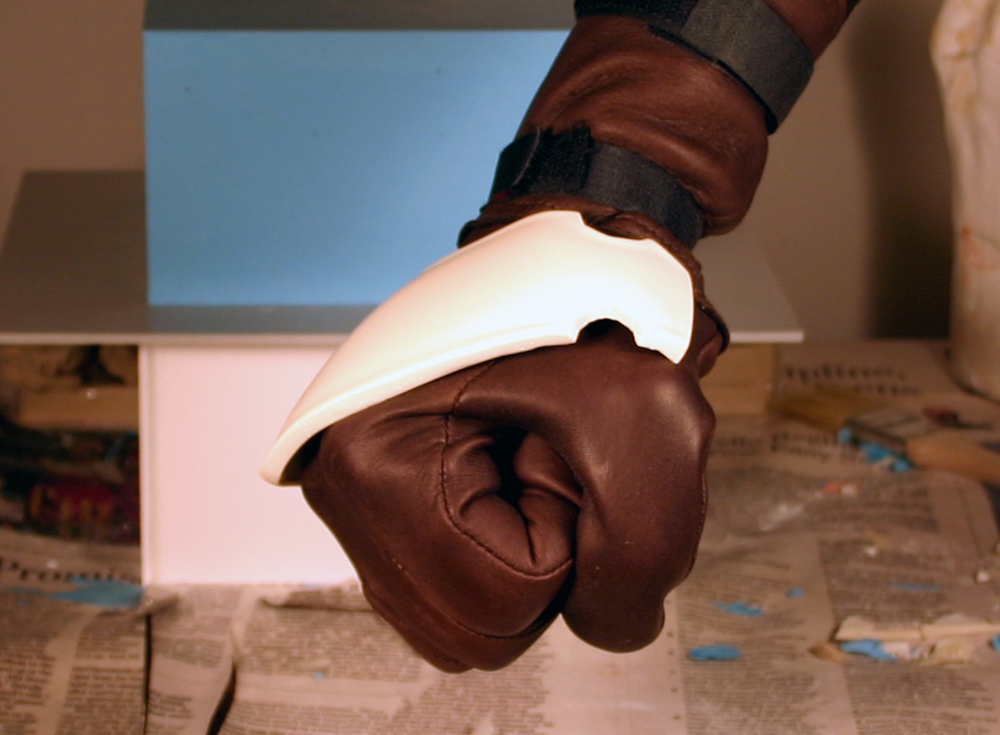

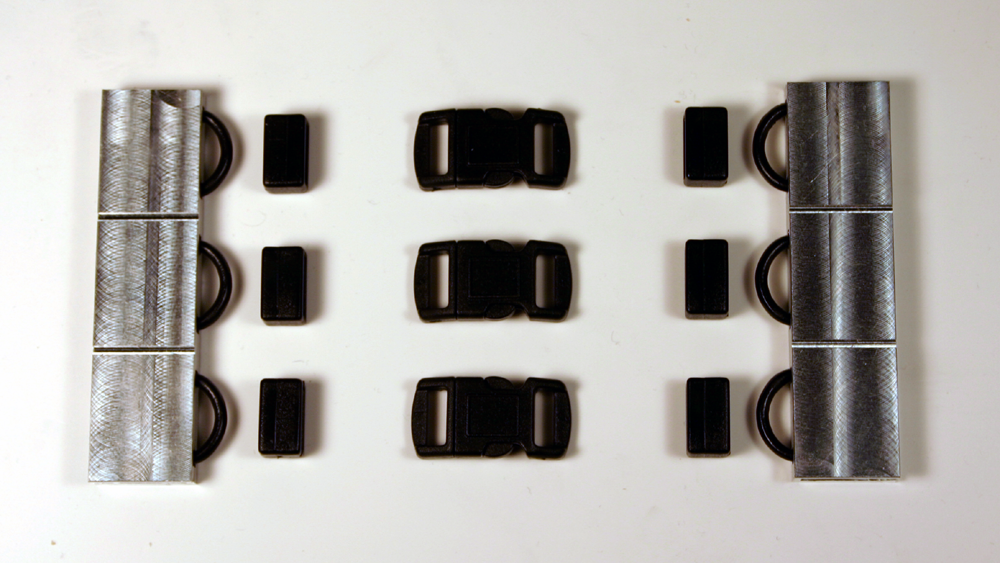

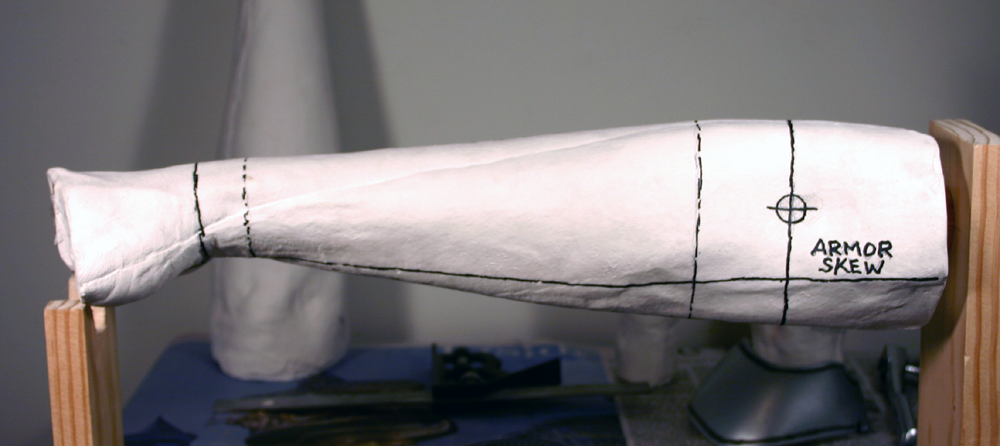

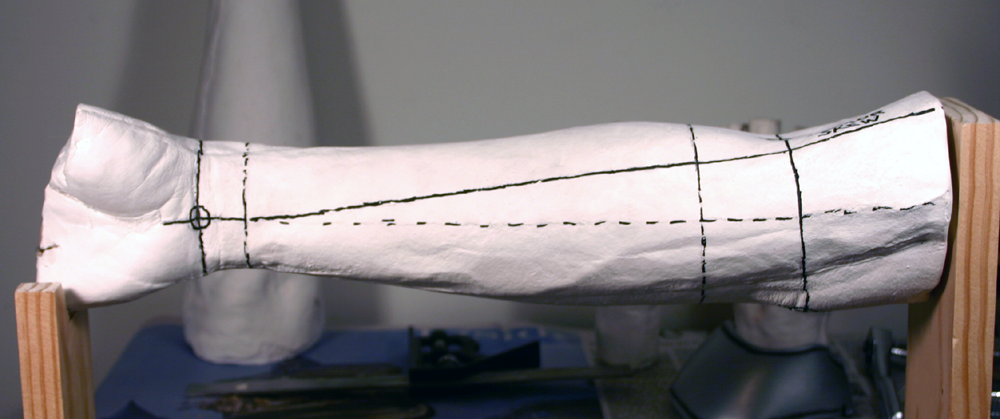

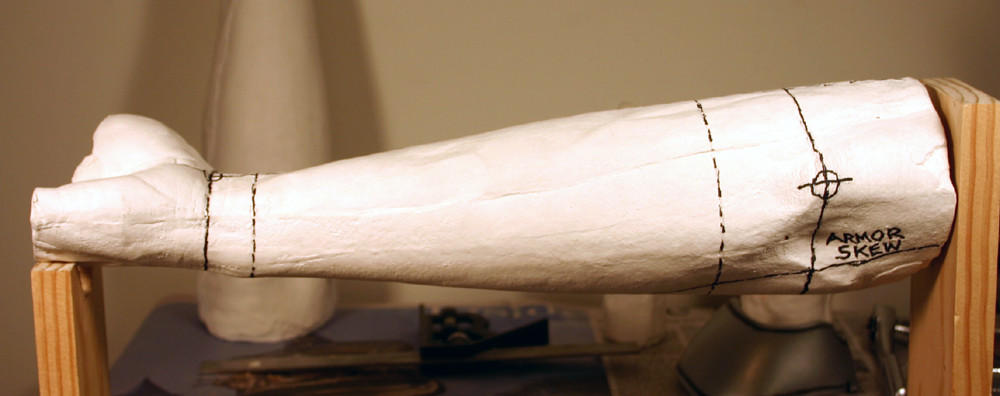

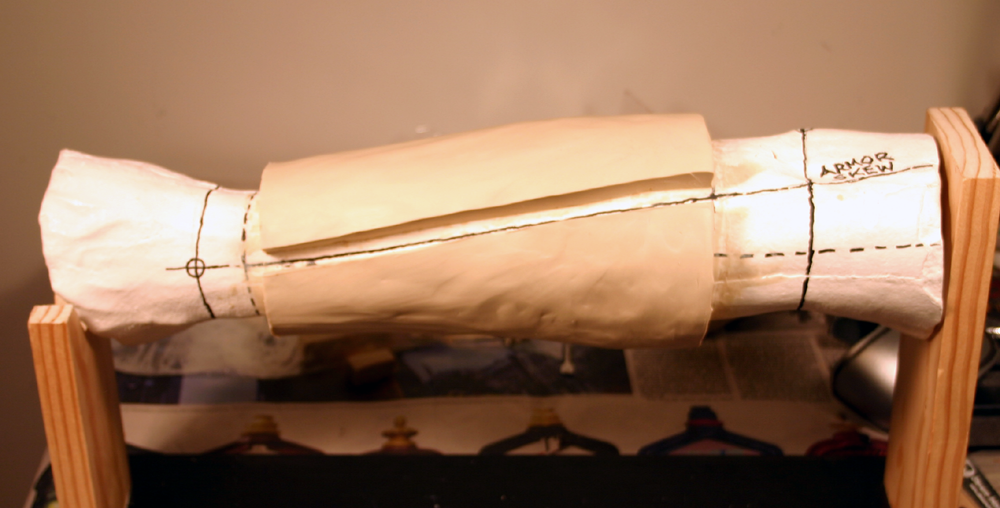

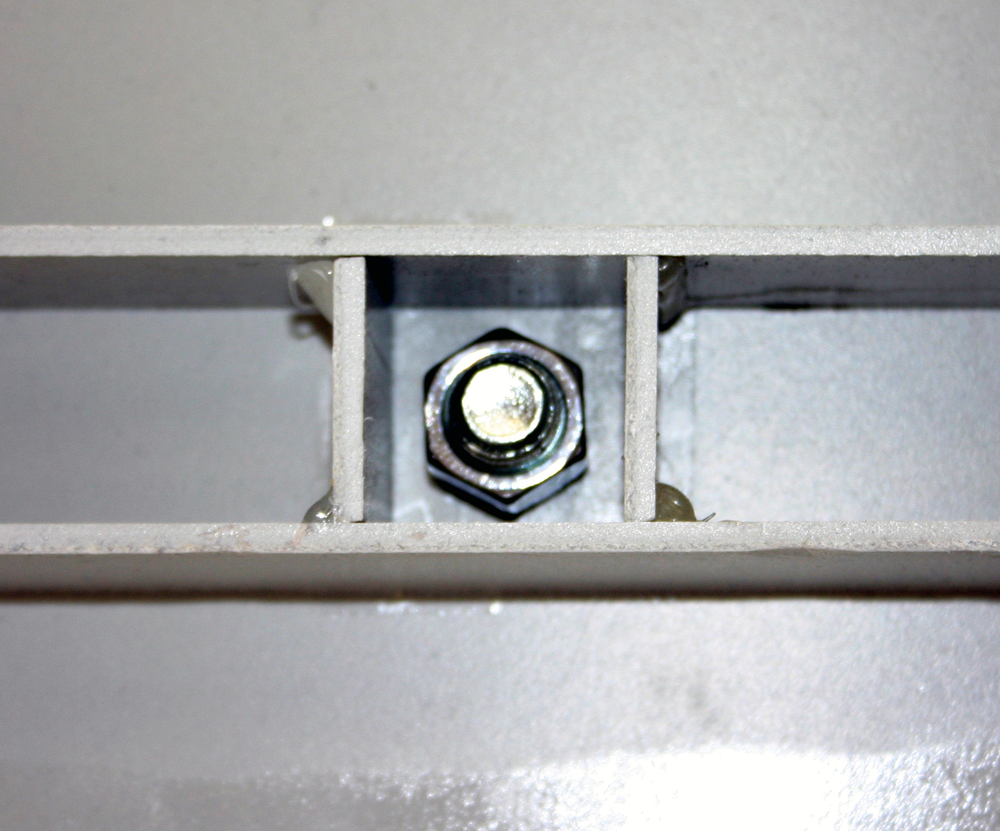

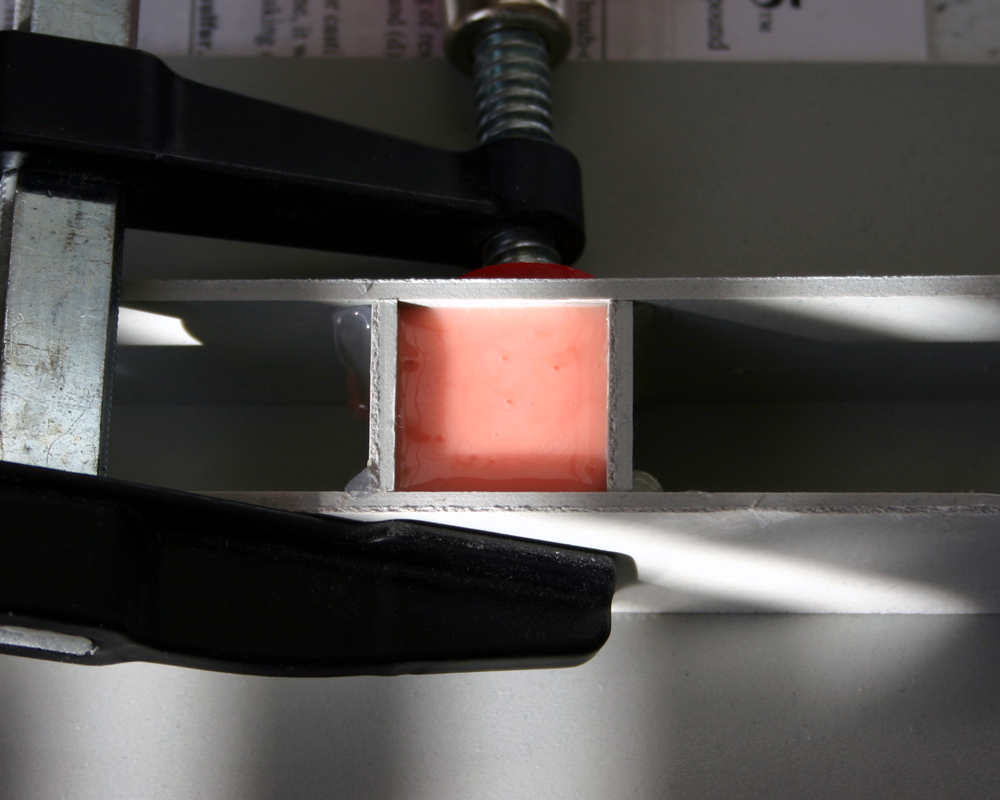

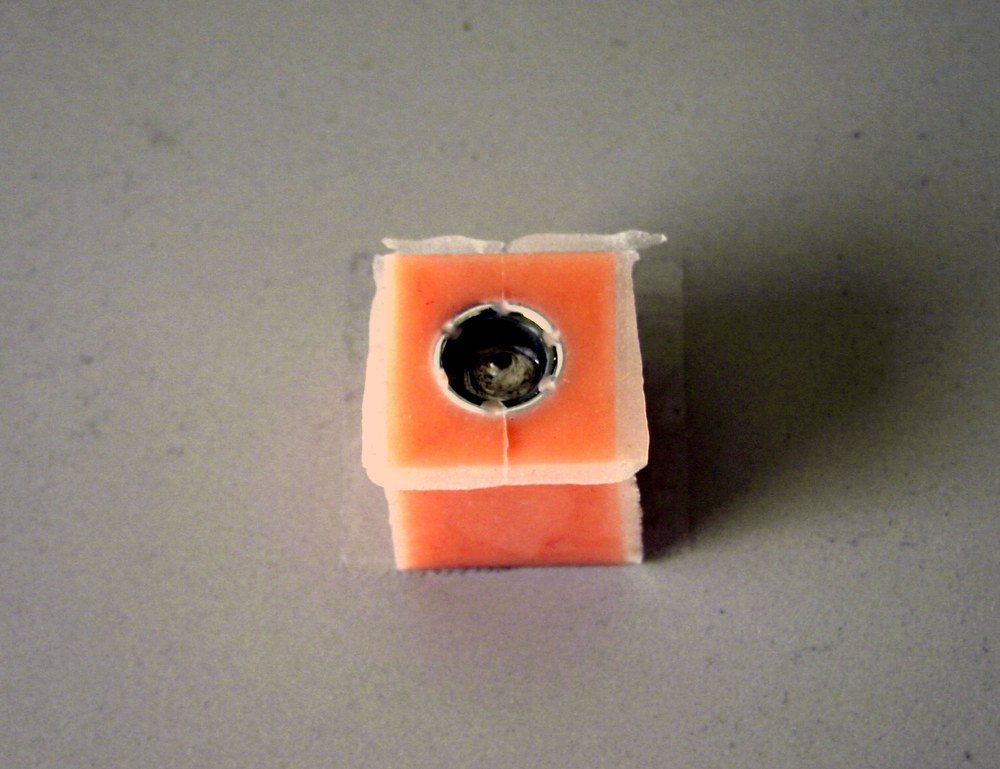

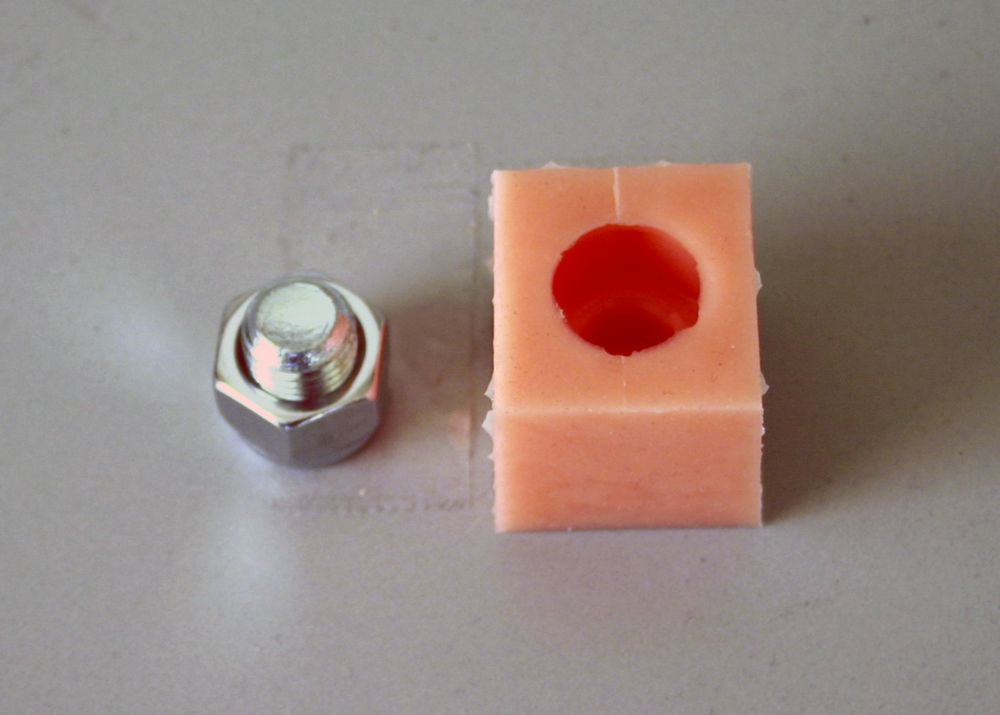

For these vambraces, the plan is to have the main front & rear halves hold snug to the forearm at their lowest point just above where the wrist clip wraps around the wrist. To hold snug, I will have a soft neoprene band wrapped around the forearm and the plastic armor squeeze this band as snug as possible without cutting off circulation during normal wear. This is the key to the mounting system and can be spirit-gummed to the skin if necessary. The neoprene band will be a couple inches wide and 1/4" thick. Limiting the width of the band will allow for some twisting at the wrist, as the armor assembly will rotate around the forearm freely above the squeeze band. The assembly skew mentioned in the last post also allows for some forearm pronation while the elbow is bent. Without the skew twist the elbow guard would dig into the upper arm and prevent any bent-elbow pronation. Supination is no problem as you can see, since the elbow guard would rotate outward around the arm.

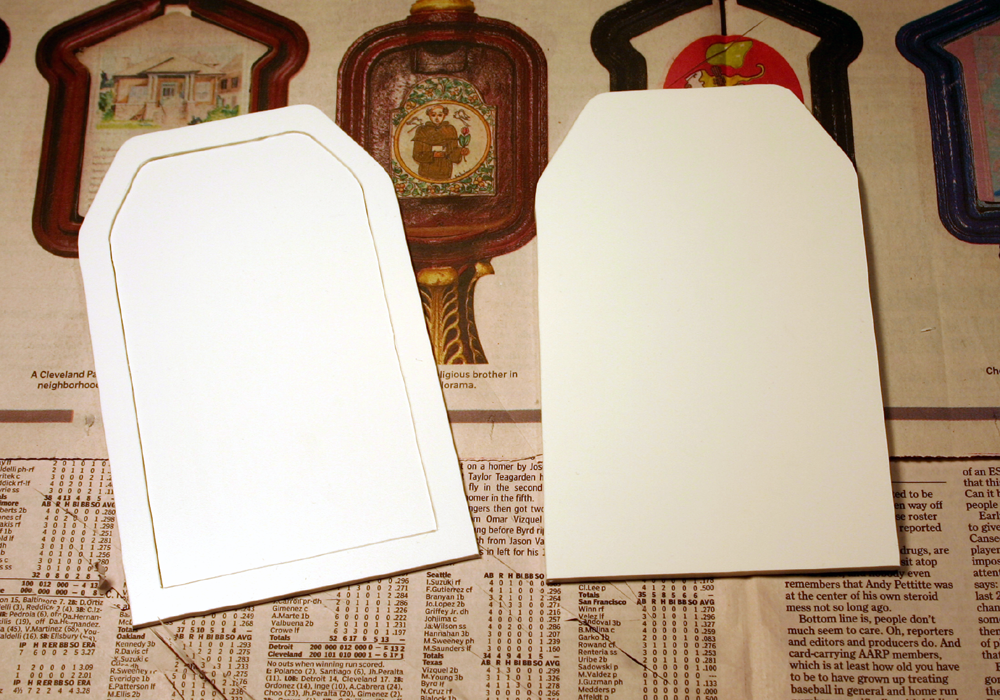

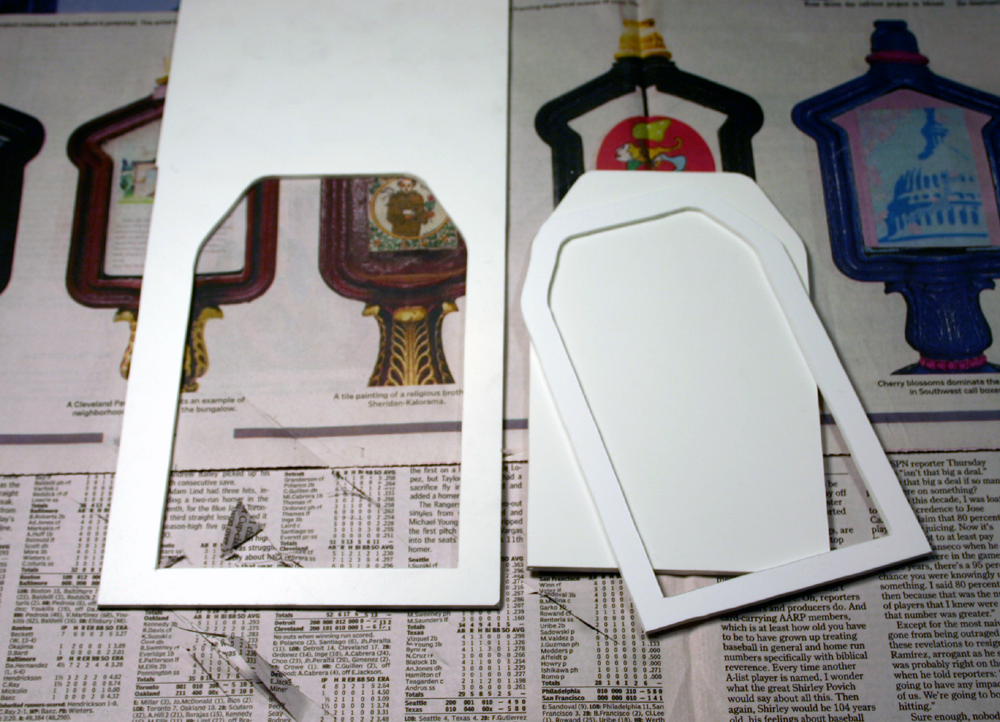

So given the necessary 1/4" squeeze band (and corresponding 1/4" spacing off the skin through the upper half of the assembly) and the approximate 1/4" thickness on the front/back vambrace halves, the sculpt for those parts should come off the armature about half inch. When I visualized that I was pretty sure that would make the scaling too thick, but after checking the ratio of the CG render to the dimensions marked on the armature, 1/2" off the arm looks just about perfect. I realize the elbow guard has to fit between the main vambrace halves and the skin, but I can cheat both parts thickness to 3/16" where they join and still be OK.

I also discovered that the circumference of the forearm just below the elbow increases as the elbow is bent, but I believe the above design allows enough room.

All this postulating may sound ridiculous, but it sure beats having to re-sculpt the pieces.

More pix to follow.

~ Vonnor