Thanks!

Well folks, after about a week of trying to think of how to interface my switch and detachable blade to the rest of the chassis, I think I have it. Last night I stopped the mental gymnastics and actually started making the interface point a reality.

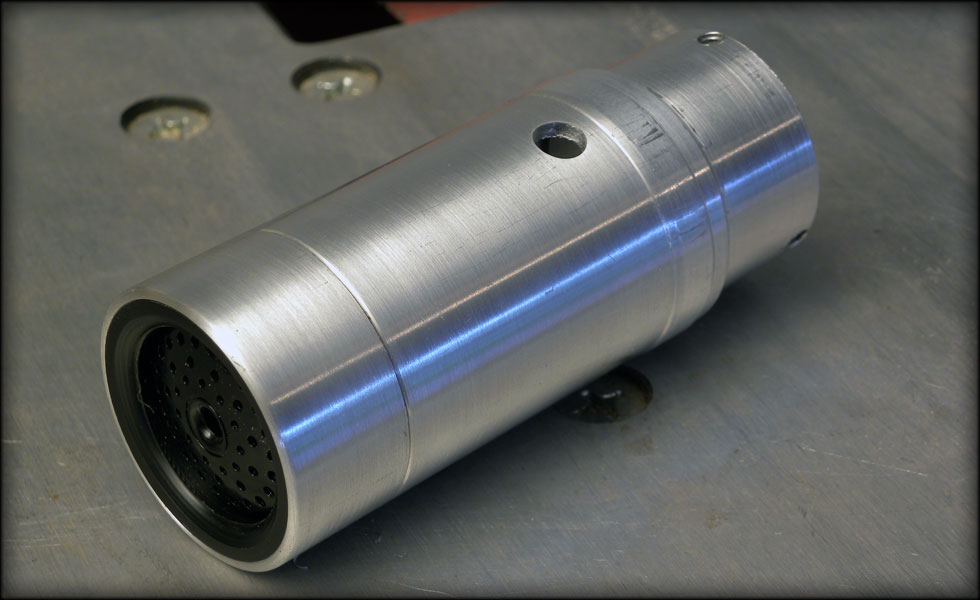

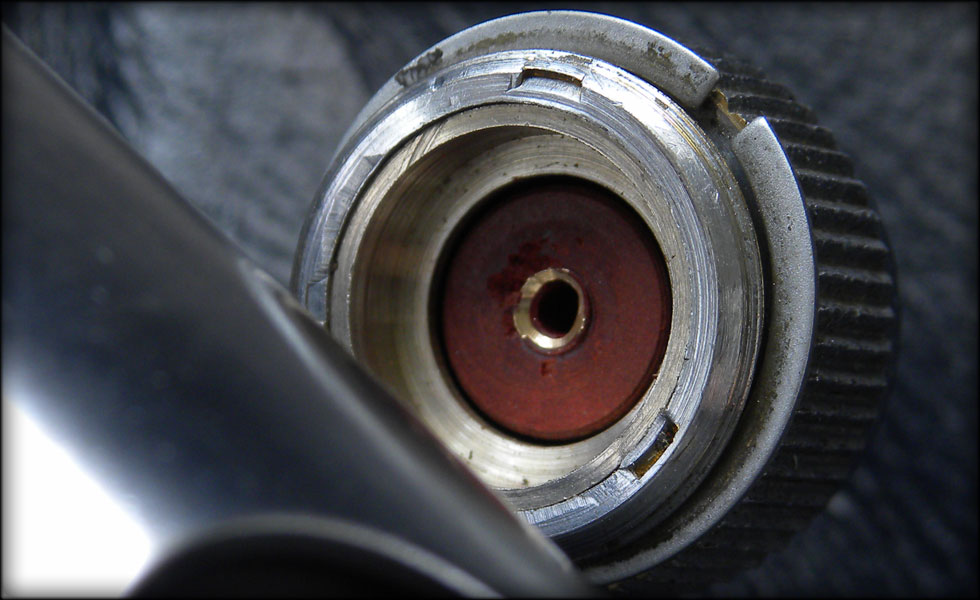

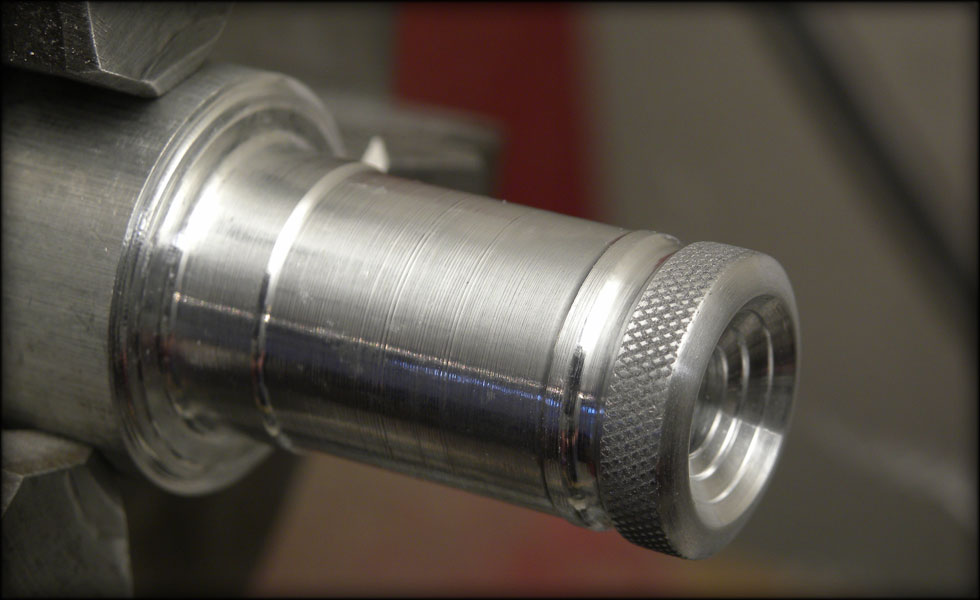

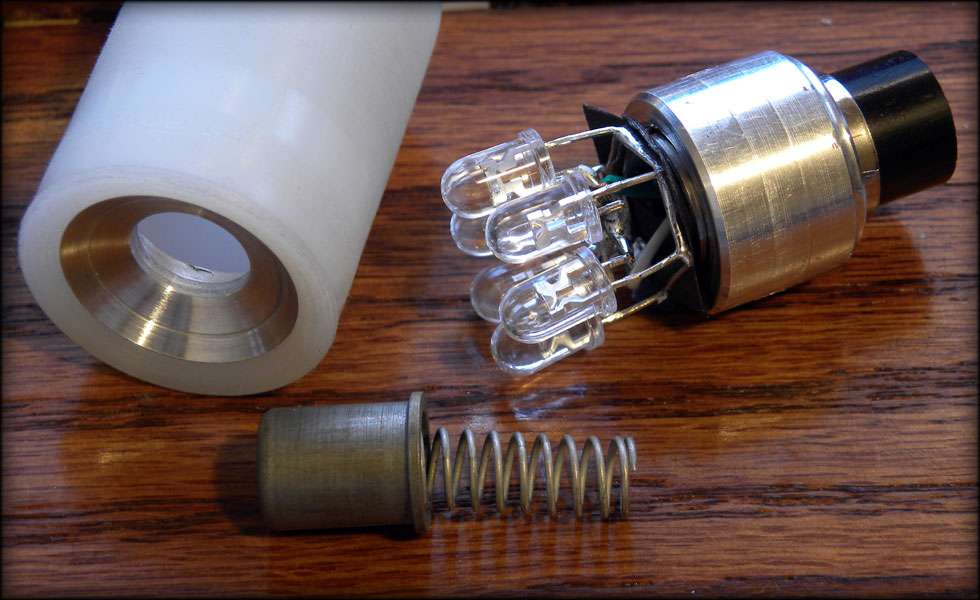

Here we have my blade adapter, modified with a big notch and filed down in the top channel to be as flat as I can make it. Also visible is my aluminum plug that inserts into the adapter, and outer collar that fits the harddrive platter retainer from the chassis, and also perfectly fits the inside diameter of the graflex housing.

The plug precisely fits snug into the blade adapter. This is where the end of the chassis will plug into the blade adapter and through this, on to the blade and plug.

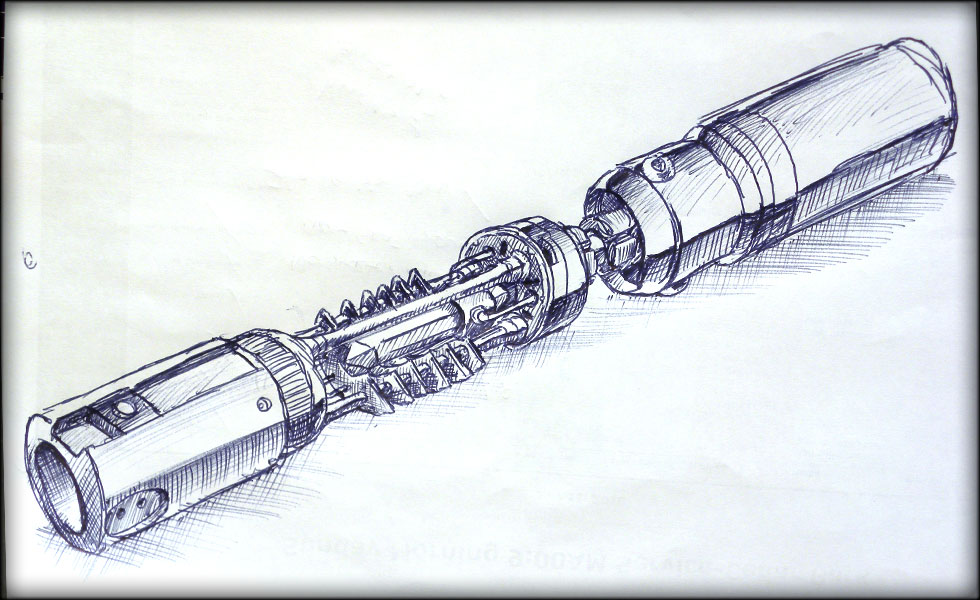

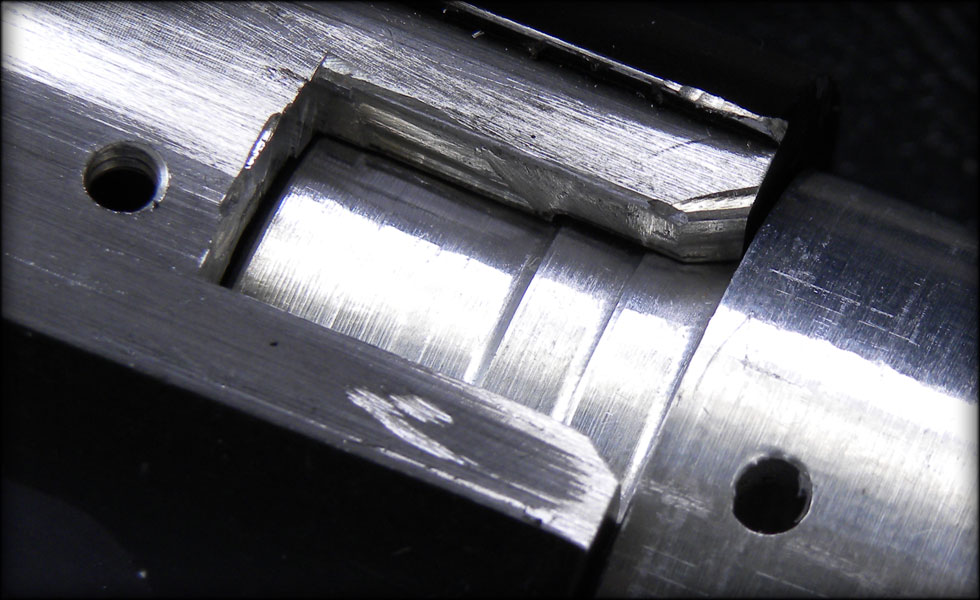

Why the notch? Well, My Pololu switch, while awesome, does need connection back to the rear of the chassis, and having a quick disconnect wire that I plug in and stuff into the thing isn't the slothfurnace way.

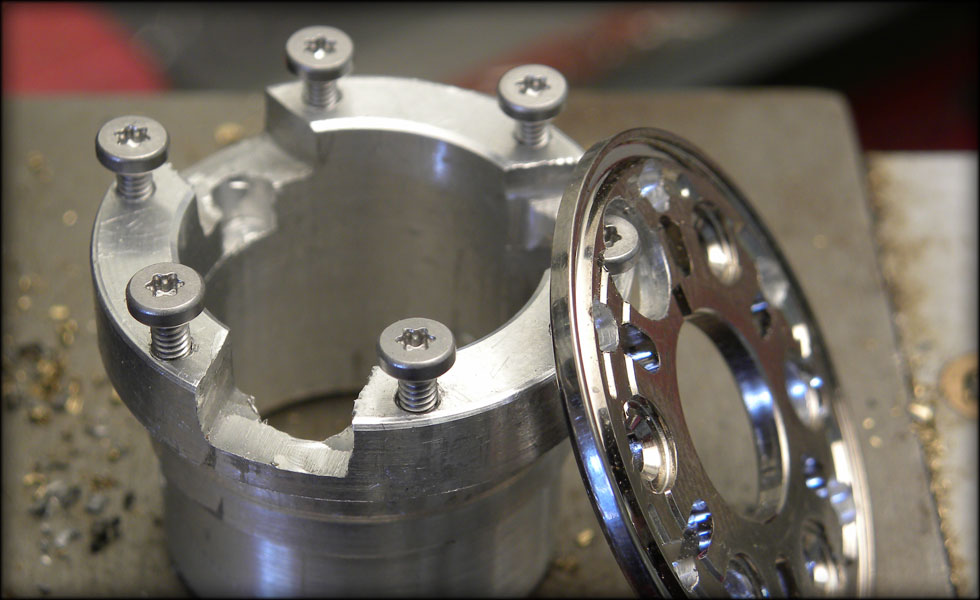

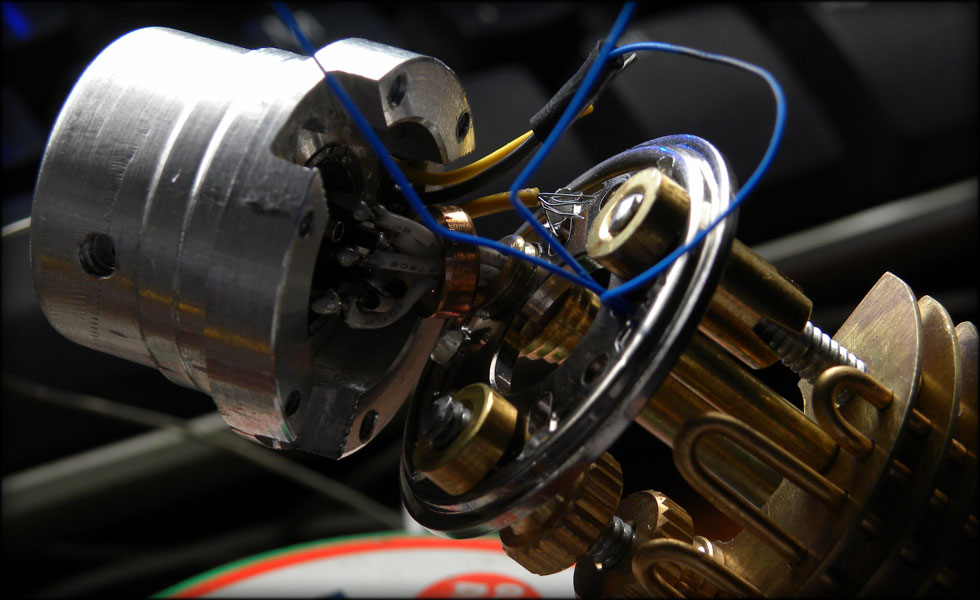

So, we make custom parts, and create a multifunctional feature. This notch both serves to index the angle of my chassis to the saber itself, therefore keeping things in line, and to allow me to use a 3 contact plug (mounted in the chassis front piece) to connect the Pololu to the back of the saber.

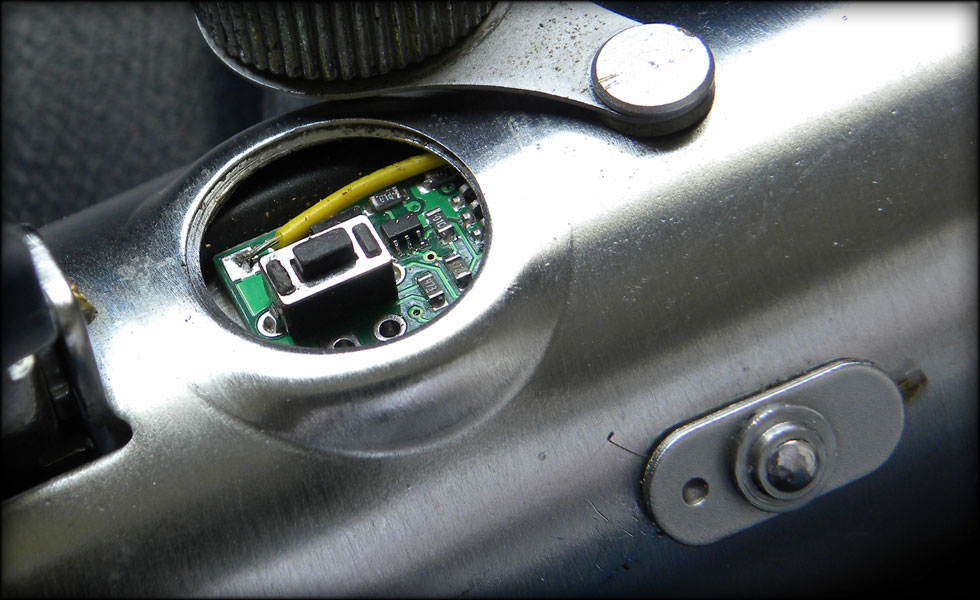

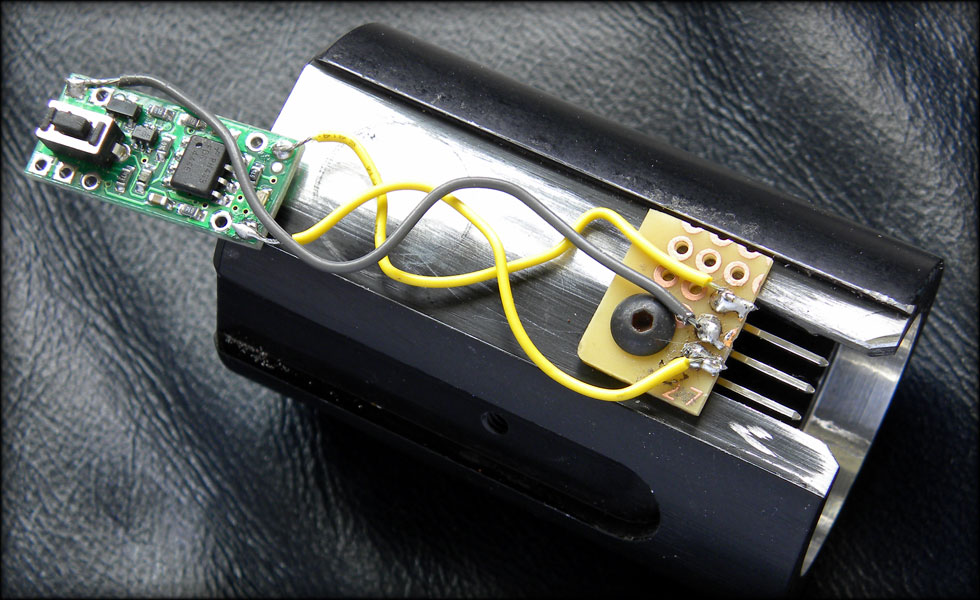

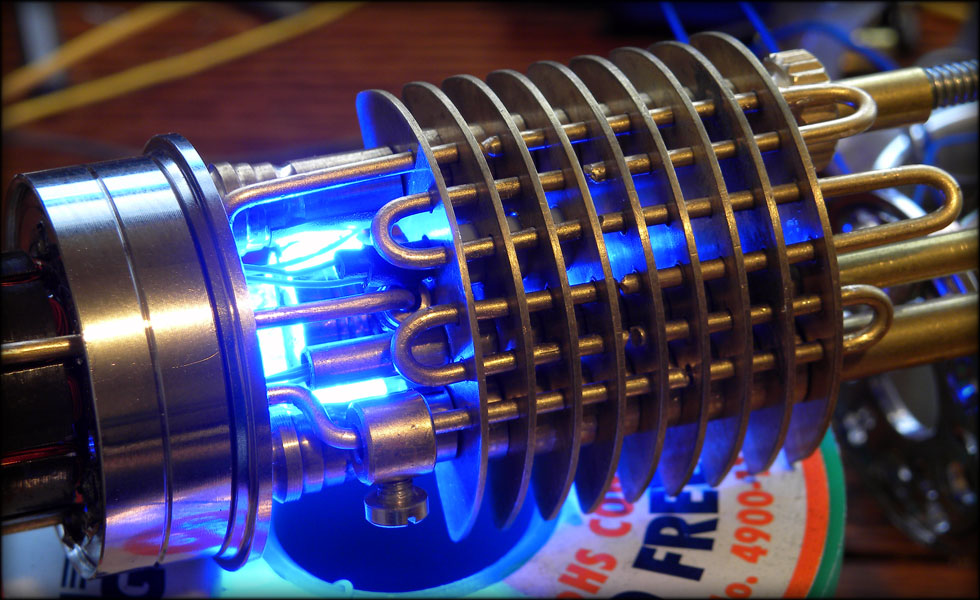

The reason for the long wires, is so that I can push the Pololu out to the end of the channel and drop it down so it all fits when I insert it into the graflex top end. The height of the Pololu wouldn't let me mount it in the channel, I have to set it out and down, slide it all in, then once the Pololu reaches the switch hole, I raise it up, and slide the adapter on in under the switch. The wires are coiled that way so that they compress into the adapter channel when the switch board gets closer to the perf board. It BARELY fits. nice and snug.

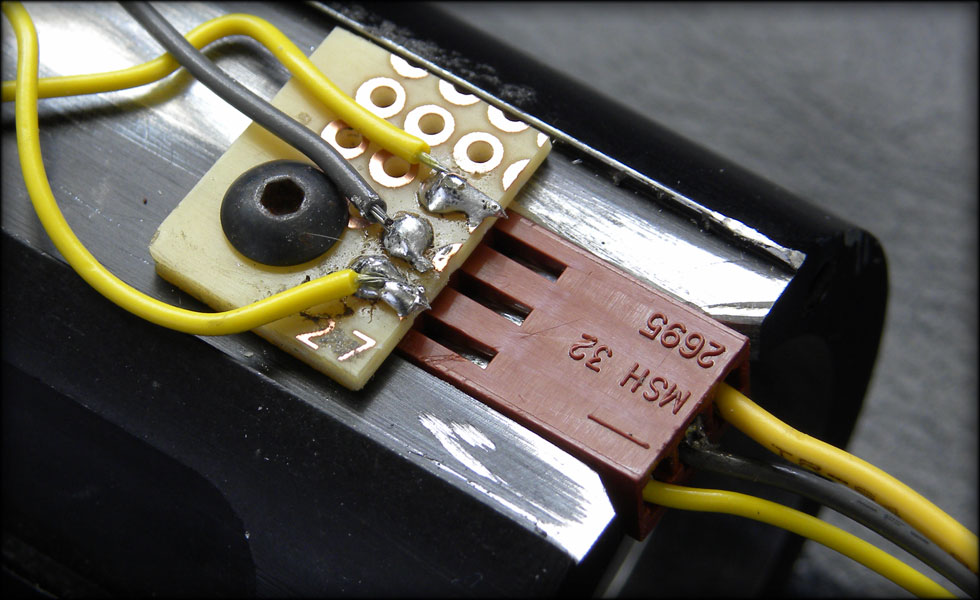

This was a scrap piece of perf board and a small screw I had in the parts bin. The flatness of the perf board across the top of the adapter channel keeps the plug stationariy up and down, and the notch keeps it stable left and right. I'll notch out on my aluminum end piece to accept the plug, and when it all fits together, it should be nice and snug.

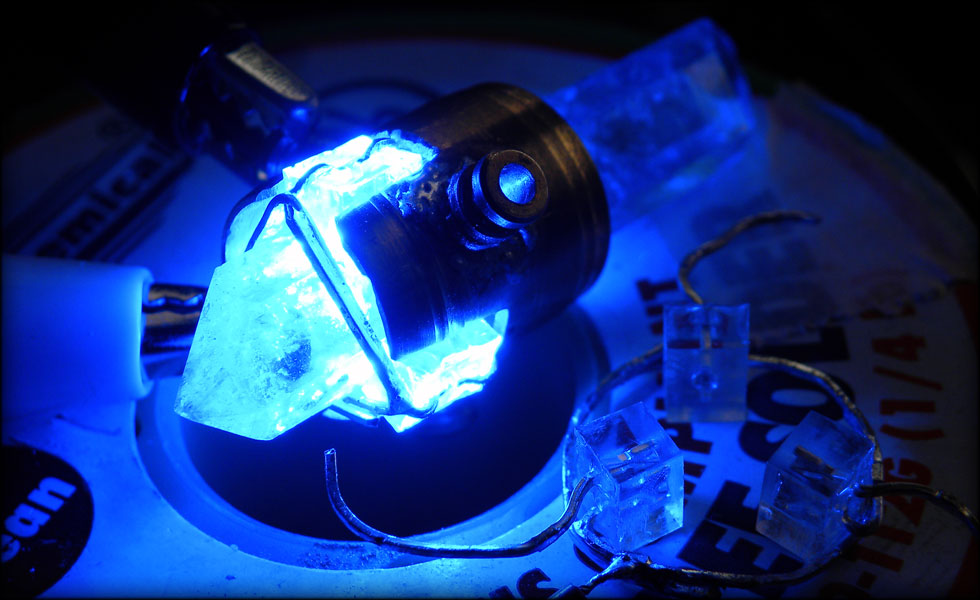

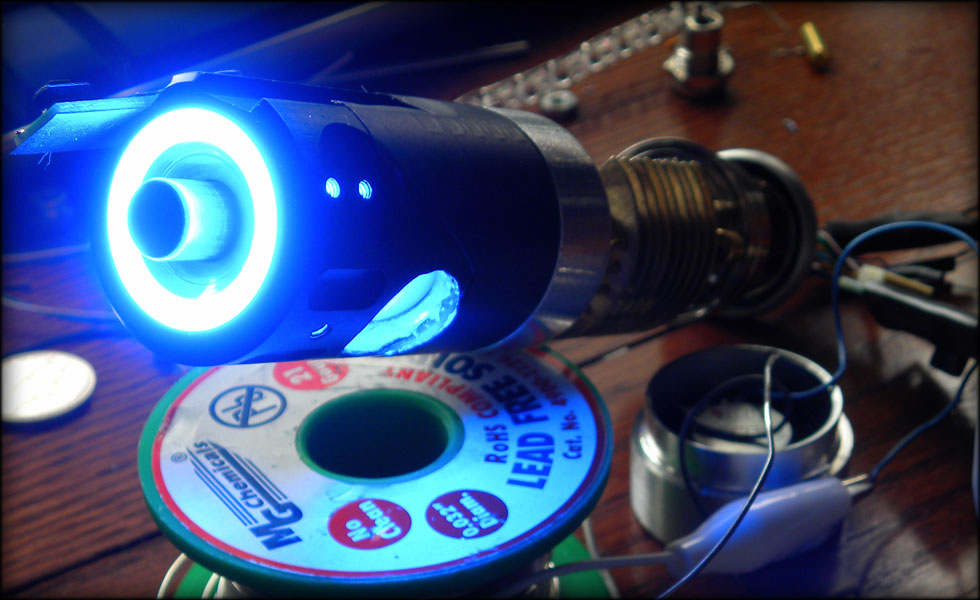

Next up, the actual blade and the non blade light up insert interface. I have the parts, but no pics yet. I need to test it first.