Did a little work tonight on my blade, I think I finally finished this step up. I had to shorten my blade a couple inches, and then I needed to finish my plug.

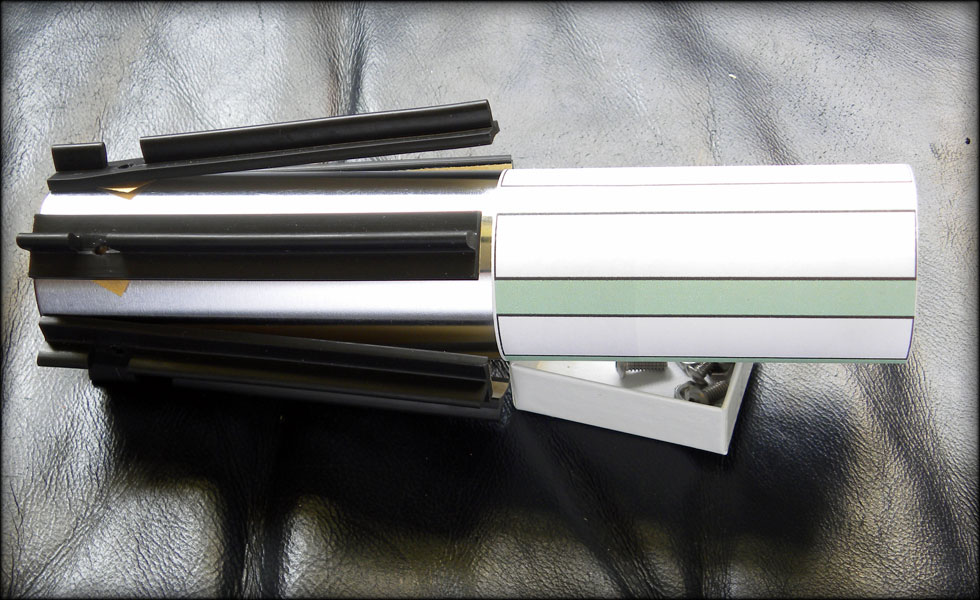

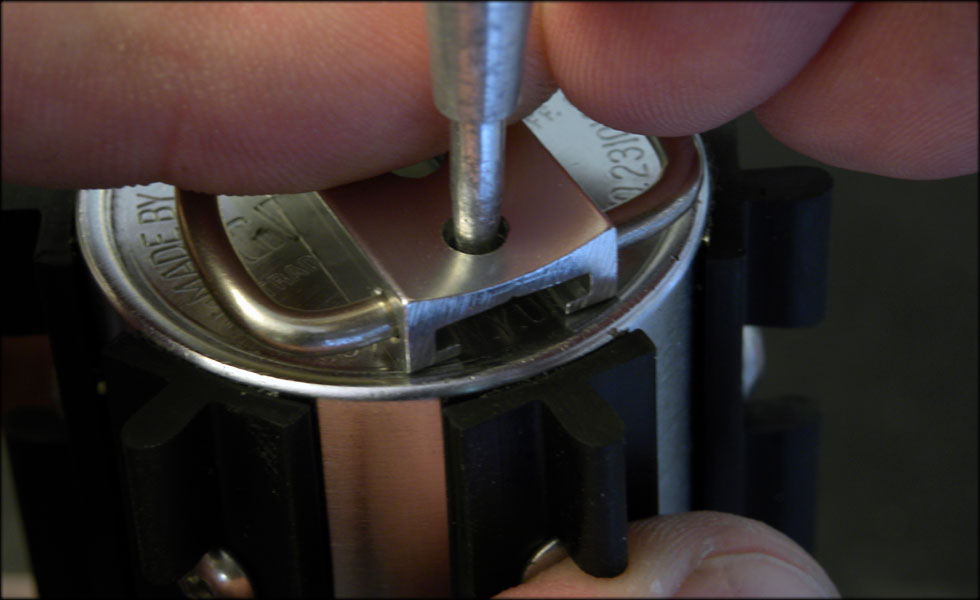

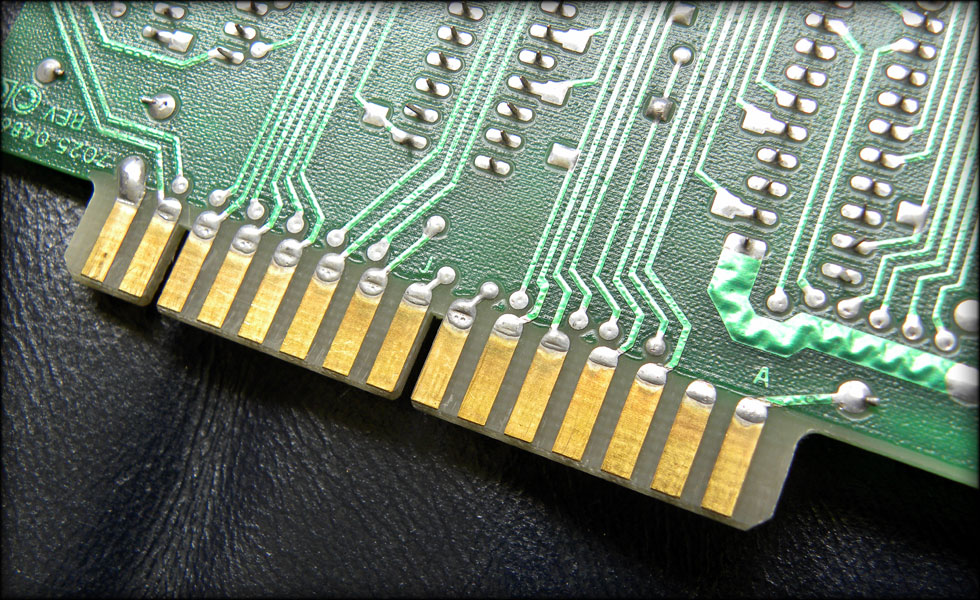

Here's a shot of the blade plug setup. I have my LED string in there, with one LED off the base, with wires, bent and cut down to fit the hole I drilled in the base DIN plug adapter. This allows me to shine a very bright light into the graflex glass eye. Otherwise, I wouldn't be getting any light in there due to the adapter covering up the glass eye port. I also had to drill and notch the DIN plug retainer bottom half to accept where my LED is sitting. It's all very close quarters in there, but it fits and works fine.

Here you see how it goes together. The LED is cut flush to the inner diameter of the blade plug. The wire slack will coil up inside the adapter.

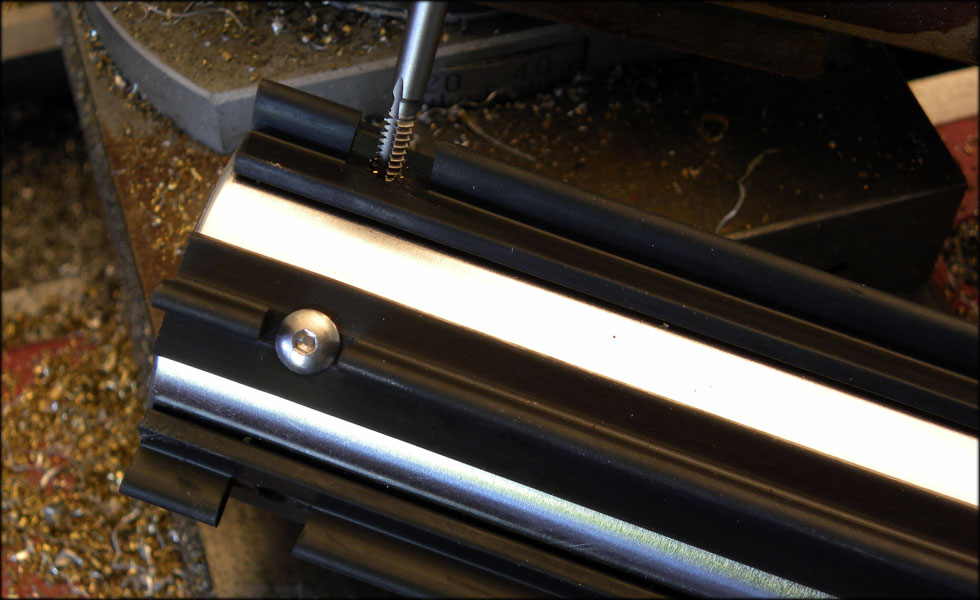

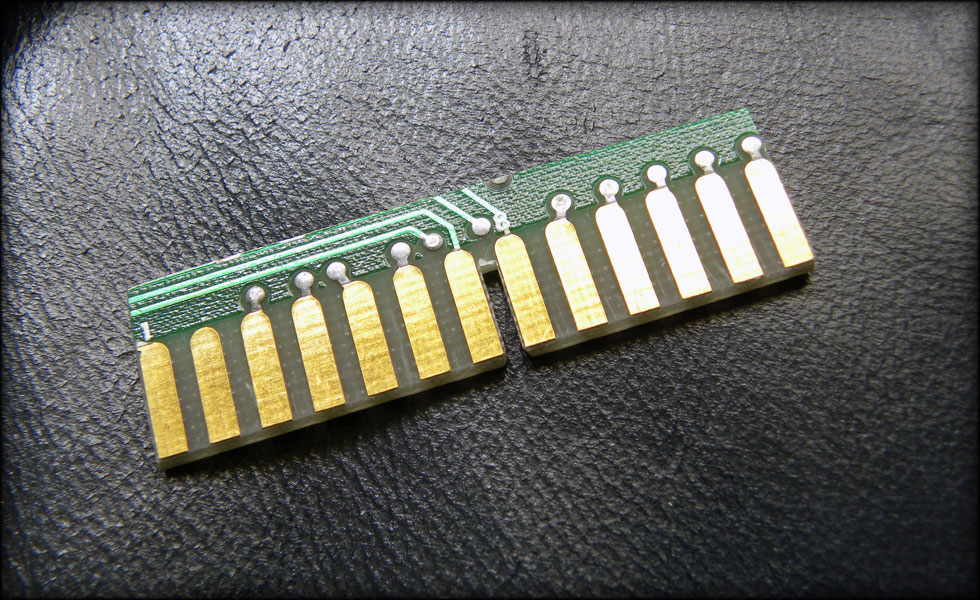

Here is the setscrew that keeps it all together, this keeps the plug in the blade adapter, and the adapter in the blade.

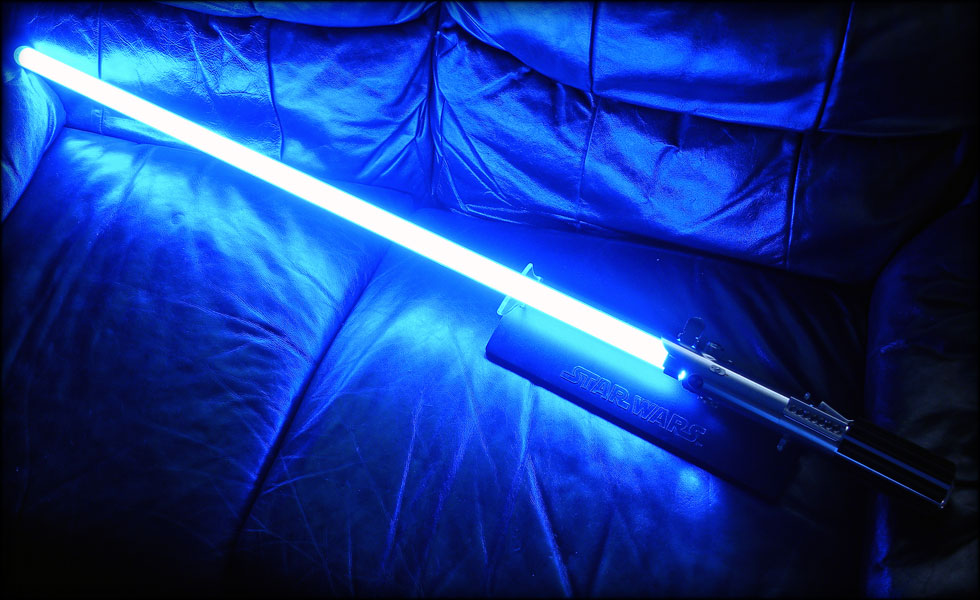

And now for what I like to call "a little moment of truth." It's when you get it all together and turn it on and see your hard work pay off. It's when you have your fingers crossed and flip the switch.

I have a little more work to do on the battery canister, I need to make absolutely sure everything is isolated, stable, and good. But I am very very close.

Here's a shot of the blade plug setup. I have my LED string in there, with one LED off the base, with wires, bent and cut down to fit the hole I drilled in the base DIN plug adapter. This allows me to shine a very bright light into the graflex glass eye. Otherwise, I wouldn't be getting any light in there due to the adapter covering up the glass eye port. I also had to drill and notch the DIN plug retainer bottom half to accept where my LED is sitting. It's all very close quarters in there, but it fits and works fine.

Here you see how it goes together. The LED is cut flush to the inner diameter of the blade plug. The wire slack will coil up inside the adapter.

Here is the setscrew that keeps it all together, this keeps the plug in the blade adapter, and the adapter in the blade.

And now for what I like to call "a little moment of truth." It's when you get it all together and turn it on and see your hard work pay off. It's when you have your fingers crossed and flip the switch.

I have a little more work to do on the battery canister, I need to make absolutely sure everything is isolated, stable, and good. But I am very very close.