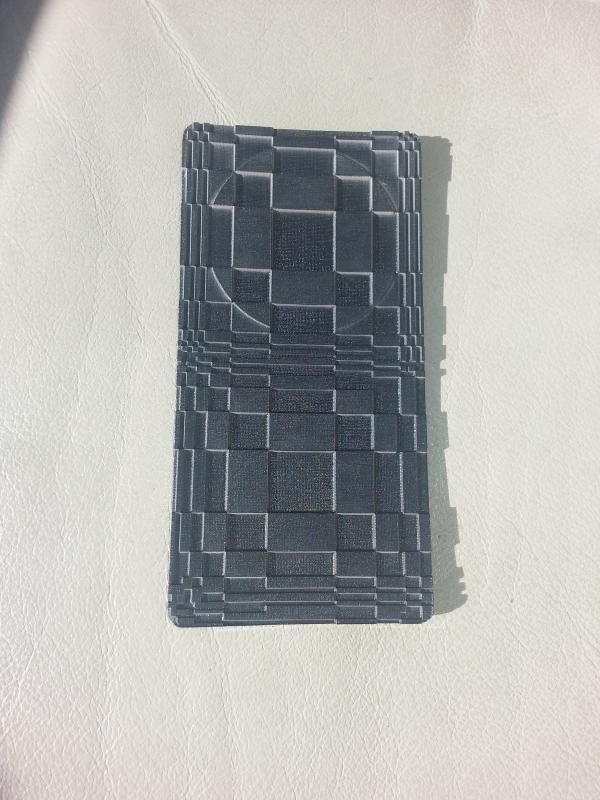

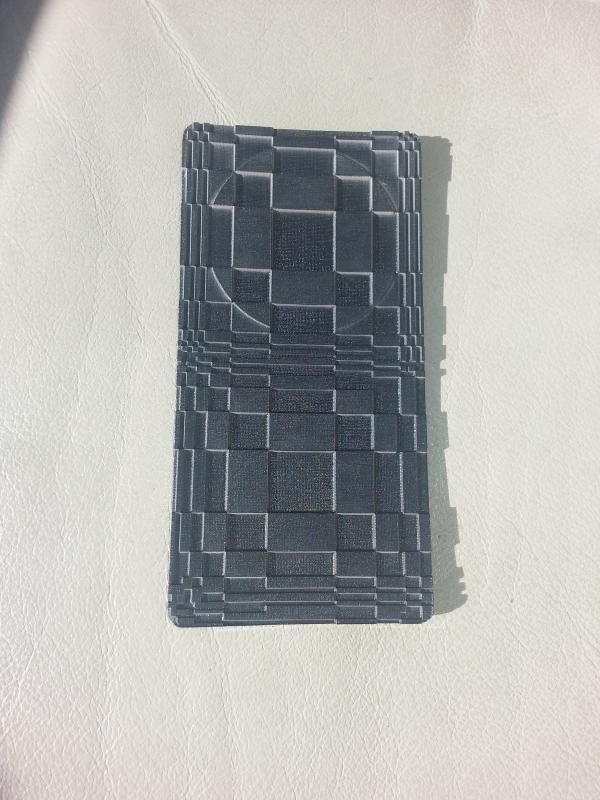

I can post something more detailed when I get back around to doing it for real, but I'm 99% sure I did it the same way they did based on the drape, shaping, flexibility, etc. You have your leather garment, and you set the designs in from the back. For this particular piece there are two layers to the design. You cut the shapes out of tooling leather, about 2 mm thick is ideal for these designs. You glue them together using leather weld, which you can get at Tandy. It looks like Elmer's but it's made for leather. You chamfer the edges, either with the correct leather working tool, an xacto, or sandpaper, then you glue them down onto another piece of garment leather. It can be the same stuff as your jacket is made from or any other thin leather. So now you have a piece of thin leather, smooth side down, with the tooling leather designs glue on top, smooth side up. Trim the thin leather to about 3/4" around the outside of your designs, then cover the entire tooling leather design with the glue, and cover the thin piece as well, leaving about 1/4" around the edges without glue. You put the piece of leather you'll be using for your sleeve, or the sleeve itself, over the top of it (take out the lining if the garment is already sewn) and press the leather down onto the designs using a smooth metal or plastic tool. Press in all the corners really well and keep going back over each area until the glue is dry. The 1/4" edge with no glue is so that you don't get a hard edge on the thin leather, you won't be able to see that piece, but it will hold the shell down so you can see all of the design. let it sit for a day to fully bond, and then you're good.