wayouteast

Sr Member

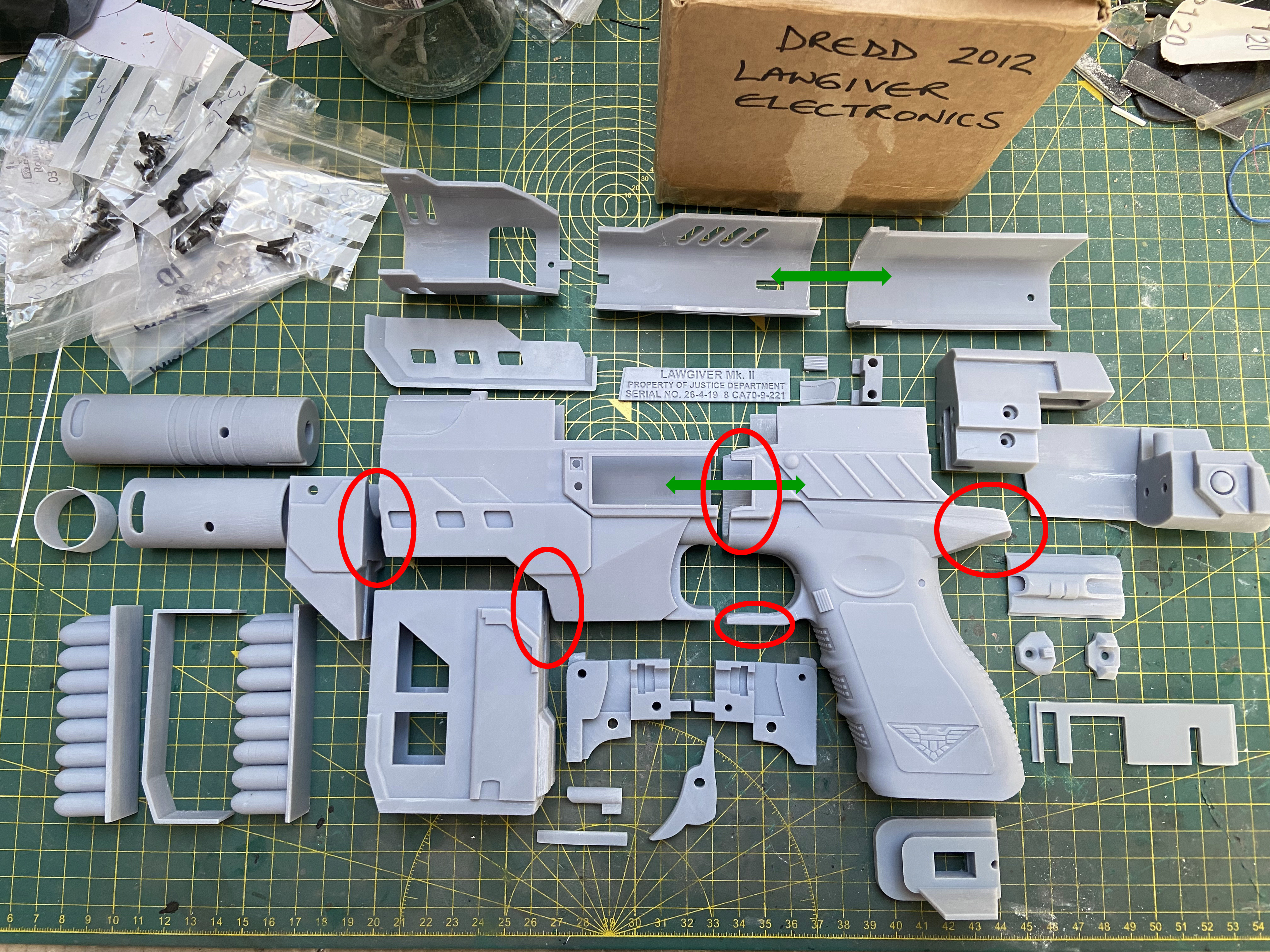

After 175+ hours of printing on my basic little Elegoo Mars printer I finally have all the parts printed for Props3D 's fantastic interactive Dredd Lawgiver and I can finally start to build this beautiful replica. I shall be using his brilliant build thread as well as the videos he's generously making available on his YouTube channel to those of us who are embarking on our own builds!

My electronic skills being extremely basic, I cheated and ordered the electronics for the kit ready-built (thanks to BeakZ for those!) so I hope I can do them justice with the 3D printed parts and integrate the interactive functions (OLED display with ammo counter, voice recognition for changing fire mode selection, neopixel LED muzzle flashes, accurate sounds, ID check and reload) perfectly into the finished gun.

The various parts of the gun were all printed using Elegoo grey ABS-like resin, which is tougher and less brittle than standard resin, and they seem quite resilient, even the thinner and more delicate parts. I used a 0.03mm layer height and 8s exposure (60s for bottom layers). All the parts were orientated and supports added in PrusaSlicer and sliced in Chitubox. I only had a couple of failed prints along the way (due to me orientating the parts wrongly the first time around) and mostly the parts printed up really well.

Because I have the first model Elegoo Mars, which only has a very small print volume, I had to cut the two largest parts (the main body of the gun and the rear shroud) in two to fit on the print plate. I did this in Meshmixer. Even then, the available print volume for the resultant split parts was so limited that I couldn't print them at their optimal orientation and had to place them in the 'best available' position (often the only way they'd fit). This left some larger than I would like horizontal overhangs which, despite adding as many supports as I could fit there, didn't print perfectly. In general, though, those parts printed really well, and once they're securely attached to each other I'm pretty sure I'll be able to fix the 'damaged' areas with some judicious filling, sculpting and sanding. I'm hoping they won't be visible at all on the finished piece. The problem areas are ringed in red on the photo.

All the parts have been cleaned up, dry-fitted, filed and sanded, drilled and tapped for screws, and a final dry fit done to ensure they all fit together and the moving parts have clearance to move against each other. The parts are beautifully engineered and required minimal clean-up, and they print as well in resin as they obviously do in plastic. They all feel nicely sturdy and the gun has a nice heft in the hand for a resin model.

Today, I've pinned and glued the parts of the main body together and glued the rear shroud halves too. I've also added some small magnets to the front of the magazine and its socket in the front of the frame. The clever magazine locking mechanism that Chris has designed feels quite secure anyway, but the magnets will hopefully just give the magazine a bit more 'grip' at the front and prevent any chance of it falling out and breaking when I'm punishing perps!

Tomorrow I'll dry-fit the gun together again and start to fix the misshapen areas from the printing with a combination of Milliput (for the larger gaps) and JB ColdWeld, especially where structural strength is a factor. I think the toughest area is going to be the back part of the OLED display frame which has a 'sag' in it and doesn't quite match up. The parts there are quite thin and will need to be sculpted to exactly match the straight edges of the forward part. I think a new frame of 1mm styrene strip around the whole aperture will help cover any deficiencies in my repair as well as helping strengthen the join, and be the key to getting a clean result. Here's hoping!

Thanks to Chris (Props3D ) and Paul (BeakZ ) for their amazing work on this beautiful prop! I'll update this thread occasionally along the way as the build progresses.

My electronic skills being extremely basic, I cheated and ordered the electronics for the kit ready-built (thanks to BeakZ for those!) so I hope I can do them justice with the 3D printed parts and integrate the interactive functions (OLED display with ammo counter, voice recognition for changing fire mode selection, neopixel LED muzzle flashes, accurate sounds, ID check and reload) perfectly into the finished gun.

The various parts of the gun were all printed using Elegoo grey ABS-like resin, which is tougher and less brittle than standard resin, and they seem quite resilient, even the thinner and more delicate parts. I used a 0.03mm layer height and 8s exposure (60s for bottom layers). All the parts were orientated and supports added in PrusaSlicer and sliced in Chitubox. I only had a couple of failed prints along the way (due to me orientating the parts wrongly the first time around) and mostly the parts printed up really well.

Because I have the first model Elegoo Mars, which only has a very small print volume, I had to cut the two largest parts (the main body of the gun and the rear shroud) in two to fit on the print plate. I did this in Meshmixer. Even then, the available print volume for the resultant split parts was so limited that I couldn't print them at their optimal orientation and had to place them in the 'best available' position (often the only way they'd fit). This left some larger than I would like horizontal overhangs which, despite adding as many supports as I could fit there, didn't print perfectly. In general, though, those parts printed really well, and once they're securely attached to each other I'm pretty sure I'll be able to fix the 'damaged' areas with some judicious filling, sculpting and sanding. I'm hoping they won't be visible at all on the finished piece. The problem areas are ringed in red on the photo.

All the parts have been cleaned up, dry-fitted, filed and sanded, drilled and tapped for screws, and a final dry fit done to ensure they all fit together and the moving parts have clearance to move against each other. The parts are beautifully engineered and required minimal clean-up, and they print as well in resin as they obviously do in plastic. They all feel nicely sturdy and the gun has a nice heft in the hand for a resin model.

Today, I've pinned and glued the parts of the main body together and glued the rear shroud halves too. I've also added some small magnets to the front of the magazine and its socket in the front of the frame. The clever magazine locking mechanism that Chris has designed feels quite secure anyway, but the magnets will hopefully just give the magazine a bit more 'grip' at the front and prevent any chance of it falling out and breaking when I'm punishing perps!

Tomorrow I'll dry-fit the gun together again and start to fix the misshapen areas from the printing with a combination of Milliput (for the larger gaps) and JB ColdWeld, especially where structural strength is a factor. I think the toughest area is going to be the back part of the OLED display frame which has a 'sag' in it and doesn't quite match up. The parts there are quite thin and will need to be sculpted to exactly match the straight edges of the forward part. I think a new frame of 1mm styrene strip around the whole aperture will help cover any deficiencies in my repair as well as helping strengthen the join, and be the key to getting a clean result. Here's hoping!

Thanks to Chris (Props3D ) and Paul (BeakZ ) for their amazing work on this beautiful prop! I'll update this thread occasionally along the way as the build progresses.