It does look just a bit OS in the pics but it looks fine.

Ideally I want to find some rubber matting with the waffle pattern to avoid all this messing around with molds and heating. Not that I don't like the effect the fumes have on my me:lol

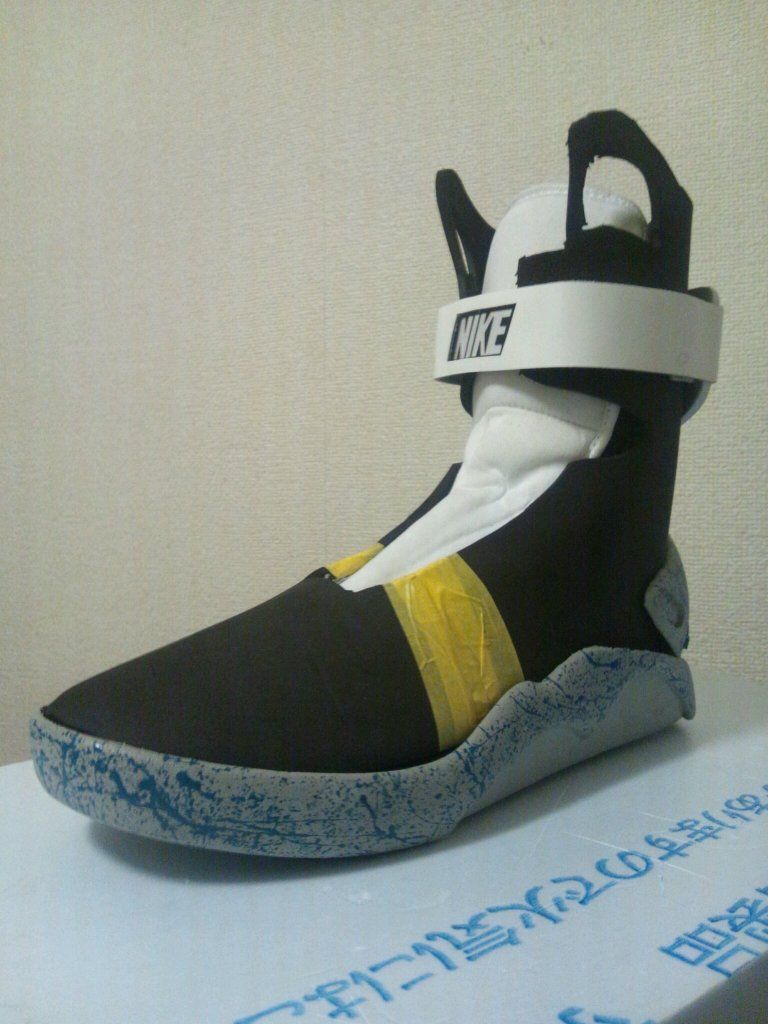

The problem is the method i'm using does not work well for a piece the size of the larger sole but I may just concentrate on getting the ovals (which are getting much easier to do well now) and only imprint the visible areas on the sides of the shoe. Considering you'd never have to see the full sole and they'd most likely go bald over time anyway, that might be what I go for.

Did you hand cut those letters?

Ideally I want to find some rubber matting with the waffle pattern to avoid all this messing around with molds and heating. Not that I don't like the effect the fumes have on my me:lol

The problem is the method i'm using does not work well for a piece the size of the larger sole but I may just concentrate on getting the ovals (which are getting much easier to do well now) and only imprint the visible areas on the sides of the shoe. Considering you'd never have to see the full sole and they'd most likely go bald over time anyway, that might be what I go for.

Did you hand cut those letters?