Very impressive. Congratulations. I've been involved in building miniguns for years, and at the range I co-own we rent time on a real, shooting minigun. Here are links to RPF minigun threads from a while ago.

http://www.therpf.com/f9/predator-minigun-setup-8188/

http://www.therpf.com/f9/replica-terminator-2-handheld-ge-m134-minigun-77931/

In the past, people have used old pool cues for barrels to simulate the taper although the real barrels have an almost imperceptible amount of taper.

I have alot of manuals, specs, pics, etc. of both real world and cinema world miniguns if you need some help. My good friend was one of the armorers who worked on the screen fired minigun from Predator (later modified for T2). He provided the real, full backstory on it inc. who shot it, how it was setup, etc.

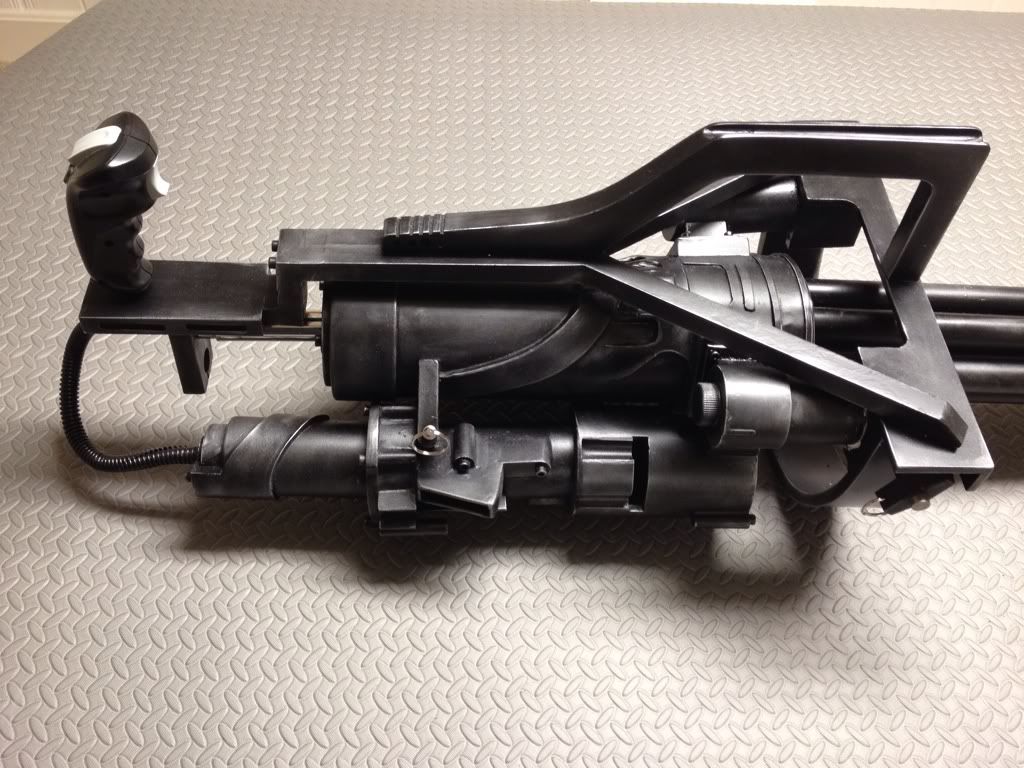

Great job. For additional realism, go to a large hardware store or online and look into "ball detent T-handles" as this is what they use to hold real miniguns together. Just a nice, affordable dressup touch. Also, put together some wire/cable leashes to safety wire/leash various nuts, bolts and the T-handles. Look at the pics of my tripod mounted mini.

Don't paint it all with the same flat black. The real minis have minor variances in component color and finish. For instance, the feeder-delinker is a phosphate like finish, the motor is a semi-glossy textured (almost like a wrinkle finish), the barrels are parkerized, the body is hard anodized dark grey.

Note, also, the carry bar that runs lengthwise on the Predator version.

Ammo chuting is (for the real minis) made by Standard Armaments Co. but it runs (new) just over $100.00 PER FOOT. You can sometimes find it used at gunshows, surplus stores, from gun dealers who specialize in belt feds, etc.

The ammo can is a helicopter ammo can for the mini that can be linked in series to other cans. For a prop, you can go to a sheet metal shop and have one made to size, or use plastic. They are O.D. in color. The pack is a US Army LC (ALICE) pack frame.

Again, amazing build. Great job.