You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Adventures in 3D Printing

- Thread starter masterjedi322

- Start date

The back does indeed look great!

The seam will more or less always be present-- unfortunate side effect of the printing process. If you look for "zseam alignment" or something along those lines in cura, you can set where it happens. I usually set mine to "Sharpest corner"-- that way it aligns with an edge and is hidden better.

Chep or teaching tech always has great tutorials on supports. I usually just turn them on in cura and leave them at default. Only thing Ill do is add support blockers from the left hand menu if I dont want supports in certain areas-- like at the top of the dome like I mentioned before.

Sometimes you can get away with no supports on horizontal pieces and rely on your machine's bridging capabilities, but if the line has any curve it will get messy like the visor did; straight lines only, up to around 10mm depending on your machine and it's abilities. There are bridging tests on thingiverse you can print to test out how far you can push your machine.

Layer separation is probably from printing the ABS without an enclosure. Drafts of air hit it and cool the plastic before it can bond properly. If this was happening all over I would guess that your temp needs to be upped, but since the back is perfect I would guess drafts. If this was in another material like PLA I would guess you wouldnt see those splits at all.

One thing that looks really good-- your layer alignment on the back is pretty much perfect. I have had some of the toughest time getting my z motor and leadscrew to play nicely and have had some prints with some wobble in them as the printer moves layer to layer

Much appreciated, both of you! So much to learn, but folks are so sharing and helpful!With the Mandalorian helmet, you'd need supports for the top of the visor section but none for the top of the dome. You can use the block supports feature in Cura for that.

Sean

TazMan2000

Master Member

I usually subdivide my objects in meshmixer to reduce the amount of supports and thusly the amount of material and time needed to print. Most times this makes the model stronger, because the separated sections have walls around them and not fill.

TazMan2000

TazMan2000

Thanks for the tips!

Printed this t-Rex skull for the kids out of bone-colored PLA. Not bad! Almost want to go print a bigger one!

Sean

Printed this t-Rex skull for the kids out of bone-colored PLA. Not bad! Almost want to go print a bigger one!

Sean

pchrisbosh1

Well-Known Member

That looks insanely good! That bone colored PLA looks pretty cool.

Iskelderon

Sr Member

Man, this turned out amazing!

Thanks, all! It’s not a perfect print, but works great for the kids!

Next up was trying some rainbow silk filament. Printed a few of these ghosts for Halloween.

Sean

Next up was trying some rainbow silk filament. Printed a few of these ghosts for Halloween.

Sean

My next project was helping a friend print some Loki horns for an Alligator Loki costume. I tried a few times on my FDM printer but just could not get the horns to print correctly…

I ended up throwing it on the resin printer. After a failed print, due to improper supports, finally got it done!

Sean

I ended up throwing it on the resin printer. After a failed print, due to improper supports, finally got it done!

Sean

TazMan2000

Master Member

I’m on with a mando bucket from great ape

Had the file for ages just never got round to printing it

Cut the top off to save on wasted filament for supports View attachment 1510767View attachment 1510768

Yes, that's the way to do it. Far less costly.

What I usually do is, drill tiny hole and stick pins in, then drill corresponding holes in the other part/s. I test fit several times, bend the pins, until I get a perfect fit. Then I glue. Very little, if any filler needed.

TazMan2000

Never tried that way, I might give it a tryYes, that's the way to do it. Far less costly.

What I usually do is, drill tiny hole and stick pins in, then drill corresponding holes in the other part/s. I test fit several times, bend the pins, until I get a perfect fit. Then I glue. Very little, if any filler needed.

TazMan2000

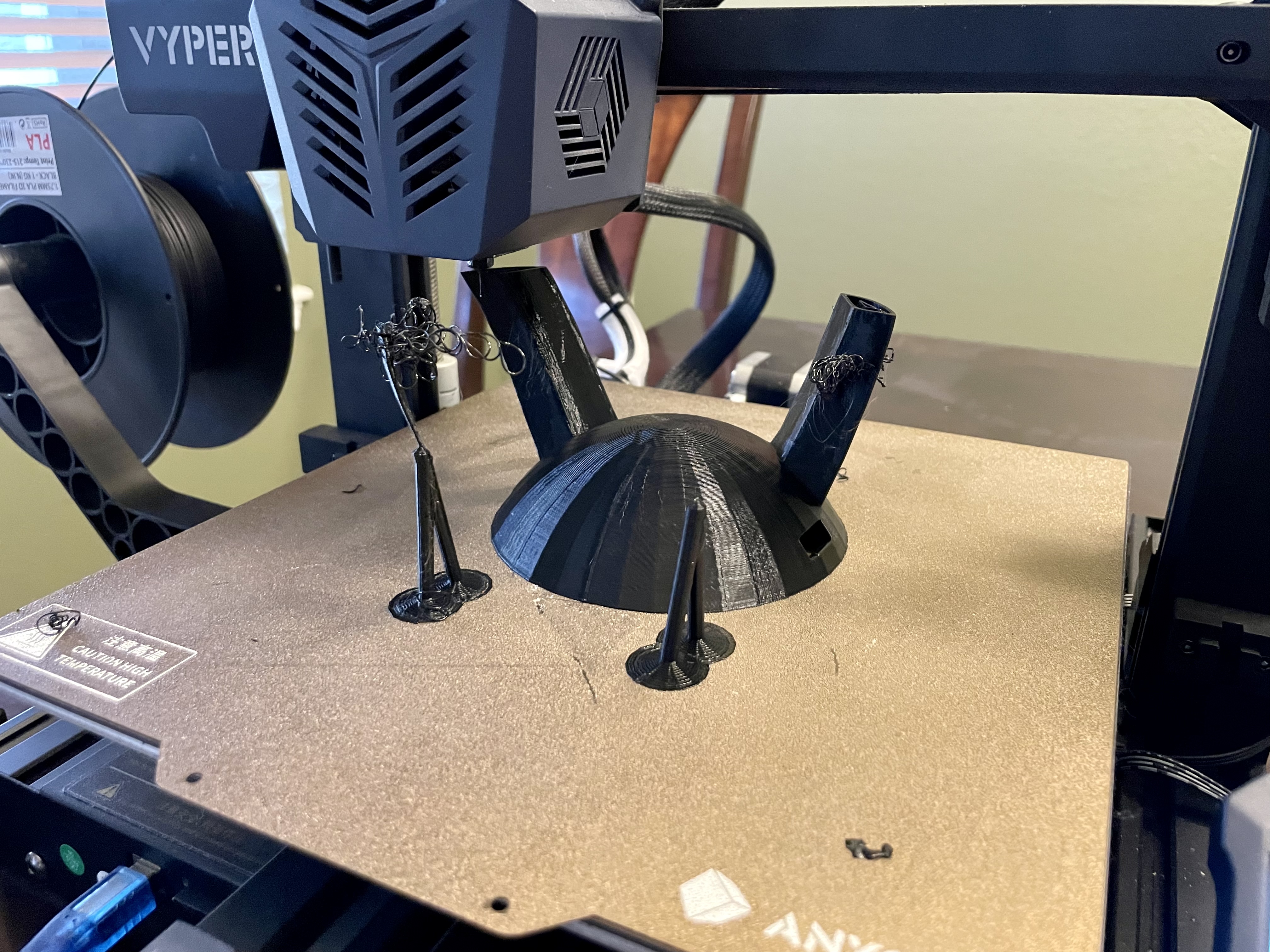

Been helping a friend with some home renovations. He and his wife are putting a tiki bar in their newly finished basement. He designed some custom tiki decorations and asked if I could print them. He split the tiki heads into 2 pieces - the eyes and then the teeth. Each piece fit perfectly on the Vyper print bed. Printed in black PLA+.

Sean

Sean

Jumped on the bandwagon and printed one of these articulated dragons. Pretty amazing that it comes off the printer “assembled” and can move.

Printing a few of these off to give away as Christmas gifts.

Sean

Printing a few of these off to give away as Christmas gifts.

Sean

JPH

Sr Member

This video RAWKS! Printed a 92% mando helmet, saved oodles o center filament!!! Just support for upper brow. Also, 8% infill for supports.With the Mandalorian helmet, you'd need supports for the top of the visor section but none for the top of the dome. You can use the block supports feature in Cura for that.

Printed in Petg, 2mm walls, but printed hot n slow.

Yeah, some minor layer shifts, but ONE PIECE!

I am a support deletin' maniac now.

Happy, fun, joy, happy panda!

JPH

Sr Member

Could you please reveal where is this clean, one-piece dragon print came from?Jumped on the bandwagon and printed one of these articulated dragons. Pretty amazing that it comes off the printer “assembled” and can move.

Printing a few of these off to give away as Christmas gifts.

Sean

View attachment 1521636

There is a new device reported at phys.org:

“Microfountain pen draws minute patterns for live cells, circuits.” From REVIEW OF SCIENTIFIC INSTRUMENTS. 3D prints next.

A second such phys.org article is “Direct writing of customized structural color graphics with colloidal photonics inks” in SCIENCE ADVANCES. Haslab needs this.

“Microfountain pen draws minute patterns for live cells, circuits.” From REVIEW OF SCIENTIFIC INSTRUMENTS. 3D prints next.

A second such phys.org article is “Direct writing of customized structural color graphics with colloidal photonics inks” in SCIENCE ADVANCES. Haslab needs this.

Could you please reveal where is this clean, one-piece dragon print came from?

/https://fbi.cults3d.com/uploaders/14456321/illustration-file/04571d57-7ffc-4e0d-ab3e-dd0f5a7f1f88/Dragon.gif)

Articulated Dragon

Print-in-place Articulated Dragon!! Huge, very flexible, and printed in one piece without supports. Just the mustache needs to be assembled after printing (see video example (https://youtu.be/le-ucwUBw5E)). It can be scaled up or down as much as you want (the limit is your printer capabilities)...

It’s just under $4, but well worth it IMHO!

Sean

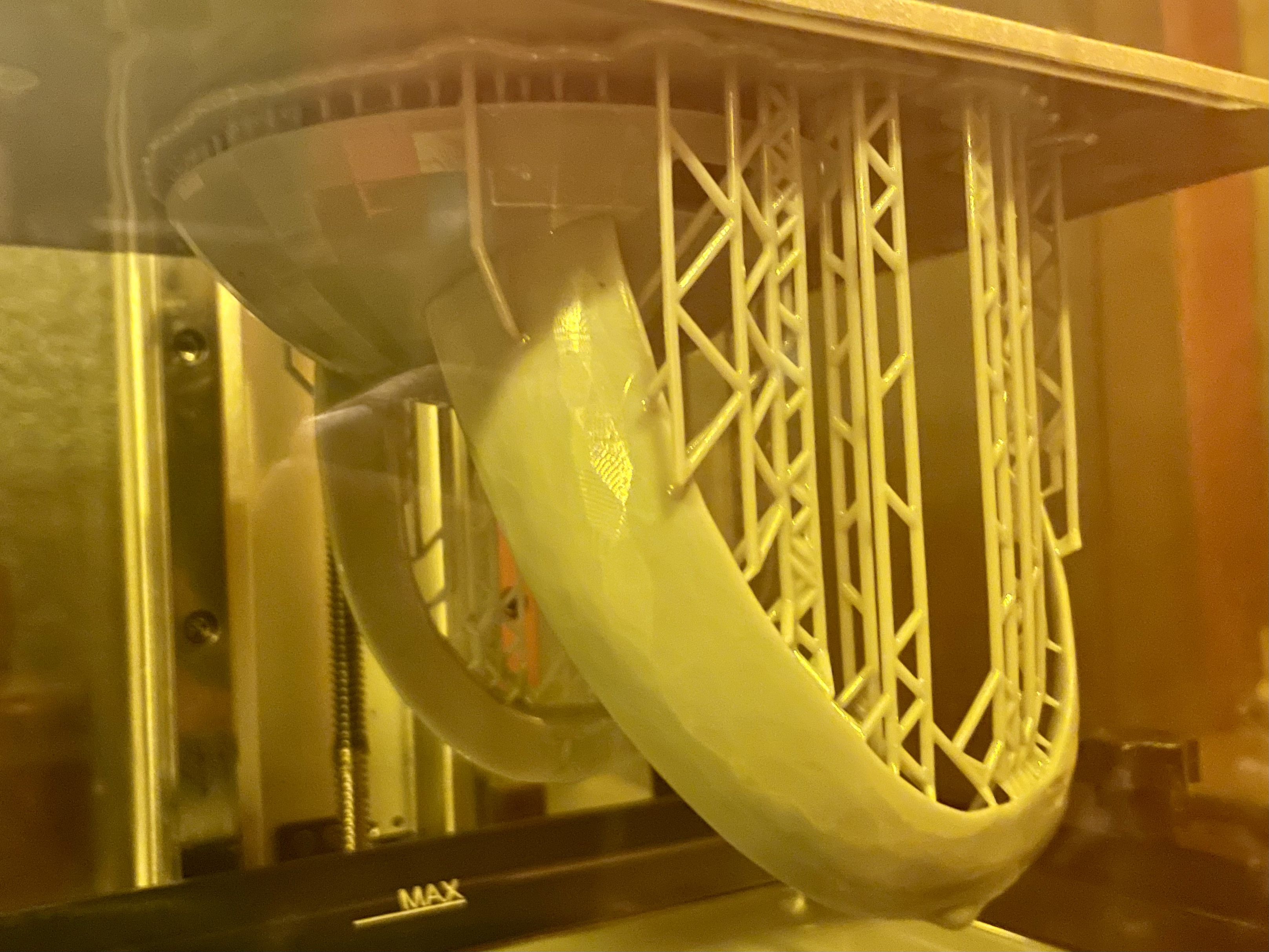

Getting back to my resin printer, I’m working on the Dune Bullfighter sculpture (available here Bull Statue – Dune | 3Demon - 3D print models download)

The bullfighter and cape printed just fine, but the bull is giving me issues. First, I forgot to hollow it. Second, I put the drain holes on the wrong side (I always forget the model is upside down in the slicer compared to how it will print). I still think the individual layers are creating too much suction against the FEP. I think I might orient the piece so it‘s more upright as to minimize the total surface area. Going to use a lot more resin for supports though…

Sean

The bullfighter and cape printed just fine, but the bull is giving me issues. First, I forgot to hollow it. Second, I put the drain holes on the wrong side (I always forget the model is upside down in the slicer compared to how it will print). I still think the individual layers are creating too much suction against the FEP. I think I might orient the piece so it‘s more upright as to minimize the total surface area. Going to use a lot more resin for supports though…

Sean

As I’ve been doing more 3D printing, I realized that I needed something bigger to tackle some of my upcoming projects…

Really excited (and lucky!) to have picked up the Phrozen Sonic Mega 8k!

Vid coming soon!

Sean

Really excited (and lucky!) to have picked up the Phrozen Sonic Mega 8k!

Vid coming soon!

Sean

Similar threads

- Replies

- 0

- Views

- 243