the.rebel.agent

Sr Member

Well, a few weeks ago I posted this:

http://www.therpf.com/showthread.php?t=41320

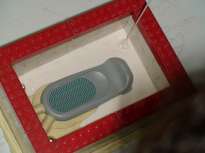

This is the piece I have to copy.

Now, I am ready to do the mold, and since I am not an expert in this area, I would love to see what do you think guys? What kind of mold will be better for the body of the comlink. I already have Silicon RTV at my workshop and some experience doing molds boxes for my resin pouches.

simple mold or two pieces mold?

http://www.therpf.com/showthread.php?t=41320

This is the piece I have to copy.

Now, I am ready to do the mold, and since I am not an expert in this area, I would love to see what do you think guys? What kind of mold will be better for the body of the comlink. I already have Silicon RTV at my workshop and some experience doing molds boxes for my resin pouches.

simple mold or two pieces mold?