cabour

Sr Member

Thanks robiwon

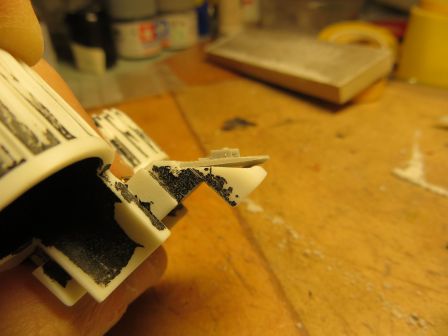

Some final details of construction are worked :

- Take care of the seams : engine hood, plate covers, belly ...

- For the air intake behind the cockpit, it had to take off the tabs, put a wedge below, glue back together and fill the seam (with two-component modeling glue and putty). After a good sanding, lines are engraved.

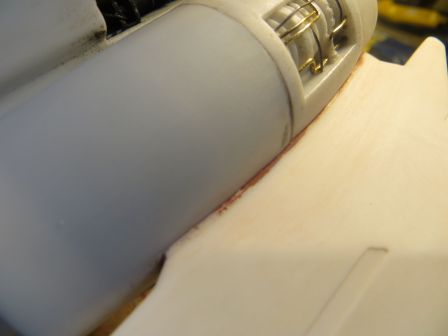

- For the wings, there was a gap of a good millimeter in some place (that I had not took car about during gluing, as I was focused to not brake the optical fibers).

It is filled again to two-component modeling glue, and after with thinner putty to fill the last defects.

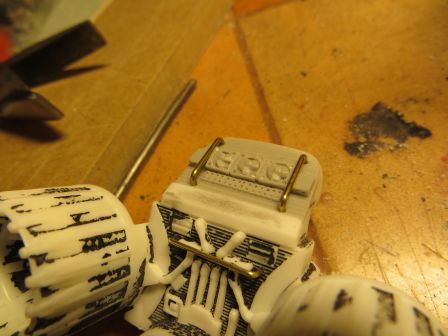

- Fill a sink marks on the cheeks of air inlets

before

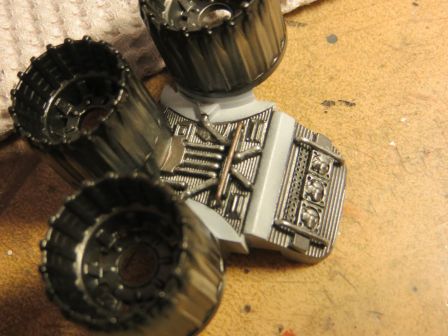

after

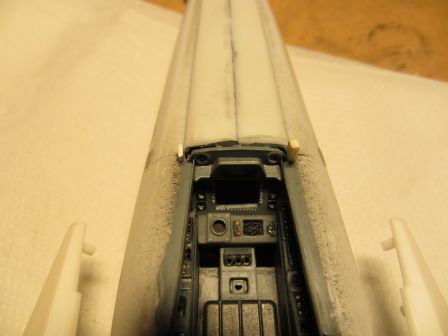

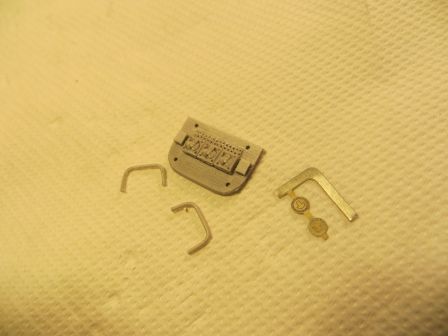

Returning to the cockpit for:

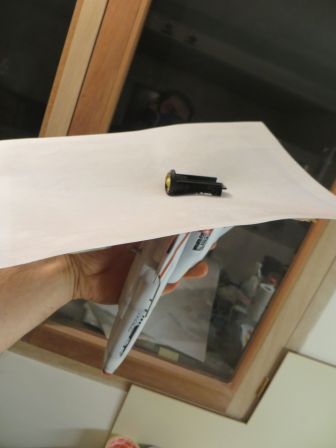

- Prepare the canopy and glue the panel behind the seat (which I had purposely left out so as not to damage during sanding the cabin

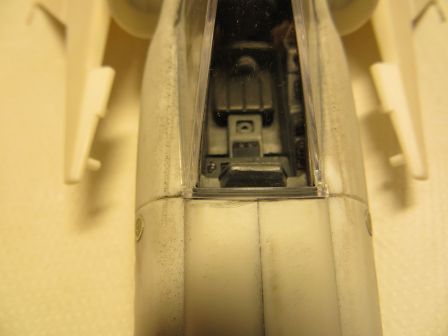

- The canopy does not lay properly because the dashboard is a little high, it was therefore necessary to sand it a little

before

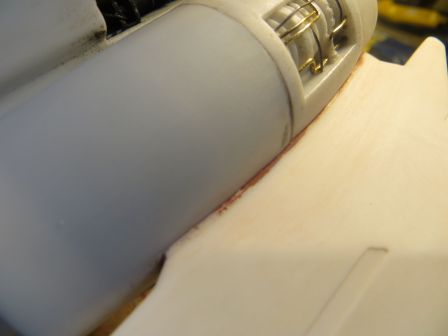

After

Some final details of construction are worked :

- Take care of the seams : engine hood, plate covers, belly ...

- For the air intake behind the cockpit, it had to take off the tabs, put a wedge below, glue back together and fill the seam (with two-component modeling glue and putty). After a good sanding, lines are engraved.

- For the wings, there was a gap of a good millimeter in some place (that I had not took car about during gluing, as I was focused to not brake the optical fibers).

It is filled again to two-component modeling glue, and after with thinner putty to fill the last defects.

- Fill a sink marks on the cheeks of air inlets

before

after

Returning to the cockpit for:

- Prepare the canopy and glue the panel behind the seat (which I had purposely left out so as not to damage during sanding the cabin

- The canopy does not lay properly because the dashboard is a little high, it was therefore necessary to sand it a little

before

After