You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

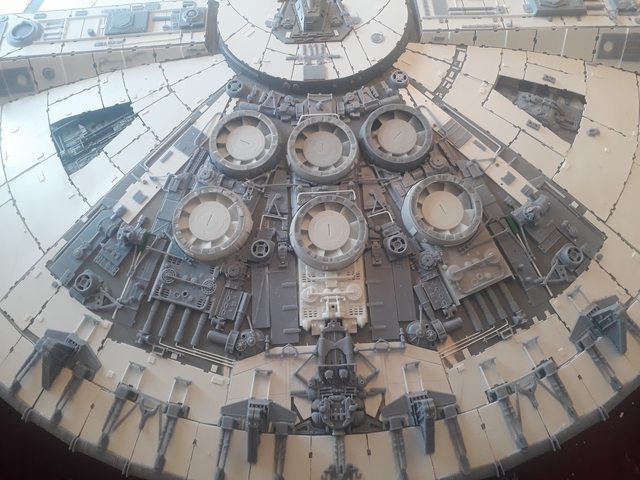

MILLENNIUM FALCON 5' REPLICA

- Thread starter GEEK1138

- Start date

A very nice job on your build - I've really enjoyed the progress!

Quick question...how are you finding the donor kit part and donor part sub-assembly fits going?

Are they generally dropping right in overall, or are you needing to adjust things a bit? Perhaps a little or perhaps a lot...?

I'm curious how different builds trend once real world kit parts and assemblies get deployed on the overall published forms.

Regards,

André

Quick question...how are you finding the donor kit part and donor part sub-assembly fits going?

Are they generally dropping right in overall, or are you needing to adjust things a bit? Perhaps a little or perhaps a lot...?

I'm curious how different builds trend once real world kit parts and assemblies get deployed on the overall published forms.

Regards,

André

A very nice job on your build - I've really enjoyed the progress!

Quick question...how are you finding the donor kit part and donor part sub-assembly fits going?

Are they generally dropping right in overall, or are you needing to adjust things a bit? Perhaps a little or perhaps a lot...?

I'm curious how different builds trend once real world kit parts and assemblies get deployed on the overall published forms.

Regards,

André

Thanks Andre...I actually haven't used any donor parts on this build. No kits were bashed in the making of this model

I am endeavouring to model the parts as accurately as possible so there is some relation I suppose. The tendency is to model larger, based on purely photographic reference, so I model everything with the Falcon master model overlaid for scale perspective. The sub-assemblies all need a larger hole cutting back of the outer shell before inserting, and then repairing the skin to the required aperture, and then plating over the joins. I'm sure this is the case with actual donor parts. It may be possible to re-design the shell with the holes precut and have access to the inside to insert the assemblies. Probably like the PG Falcon. No complaints about the master model though...it's a masterpiece.

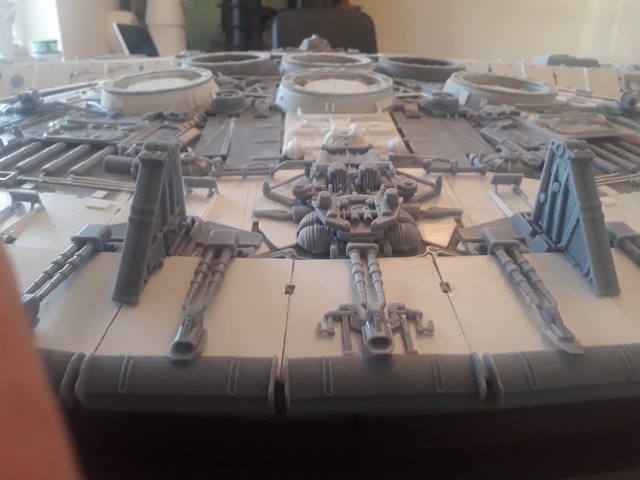

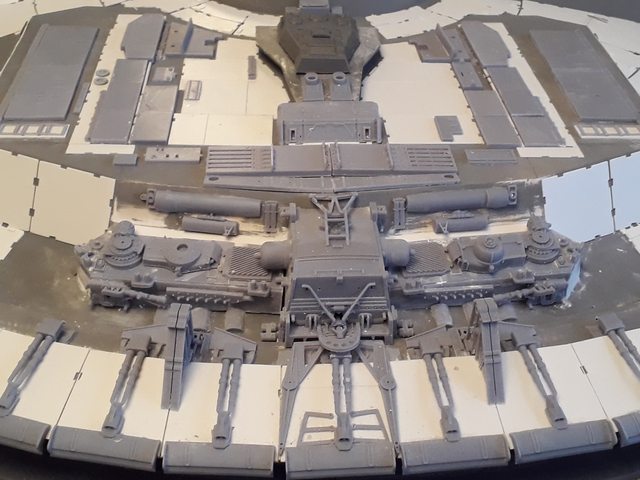

OK finished modelling the Tail Array...the cluster of greeblies behind the Lower Deck;

OK, so I have pretty much finished the Dorsal side of the Falcon, except some pipes and surface greebs... And I think I have now modelled every donor part for the whole build.

Feels like a significant milestone for me to get the upper deck done and really chuffed how it looks too

Also, got the Koolshade substitute from Smartlouvre and really like how it looks

Feels like a significant milestone for me to get the upper deck done and really chuffed how it looks too

Also, got the Koolshade substitute from Smartlouvre and really like how it looks

What's your I.D. and O.D. and max height on your engine vents? Something looks "off" -- but I can't tell if its my eye, the camera, or simply the placement of the greeblies around them. I don't mean to be a nag or a critic, but this thing looks Way Too Good to let "close enough" go by on the upper rear deck that gets a LOT of visual attention. Also, are those engines in temporary spots, or final position and glued down? Because on the top row, the three engines should be abutting each other so much you have to shave off some of the sidewalls, no?

Jaitea

Master Member

What's your I.D. and O.D. and max height on your engine vents? Something looks "off" -- but I can't tell if its my eye, the camera, or simply the placement of the greeblies around them. I don't mean to be a nag or a critic, but this thing looks Way Too Good to let "close enough" go by on the upper rear deck that gets a LOT of visual attention. Also, are those engines in temporary spots, or final position and glued down? Because on the top row, the three engines should be abutting each other so much you have to shave off some of the sidewalls, no?

Yep,...engine vents look too tall or something,.....everything else looks perfect

J

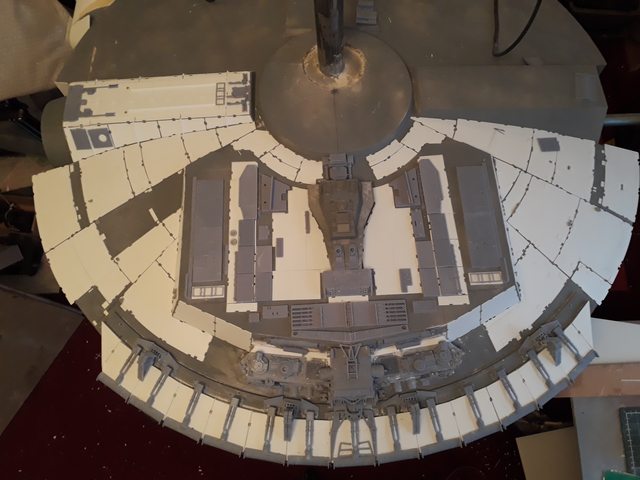

Ok so I've re-done the vents and made them lower and shuffled the top row together so they touch. I will take some more pics but at the moment I have flipped the bird over and started on the ventral side

Not glued everything down yet so might need a bit of shuffling but looks mostly there

Aside; If anyone has info on where I can get the decals from?...I'm aware of the Hampton webpage but they don't have any downloadable stuff that I can have mad, and I tried JBOTS but he is no longer operating

Also, Glass/perspex for the windows, or not? I know the filming model didn't have any but should the model?

Not glued everything down yet so might need a bit of shuffling but looks mostly there

Aside; If anyone has info on where I can get the decals from?...I'm aware of the Hampton webpage but they don't have any downloadable stuff that I can have mad, and I tried JBOTS but he is no longer operating

Also, Glass/perspex for the windows, or not? I know the filming model didn't have any but should the model?

Ventral side looks awesome!

My vote is Yes on glass for the windows that are FLAT (turret windows), but "your call" on windows that are curved (nosecone). My theory is that flat windows will photograph well, curved ones will not. But if it were me, I'd also make the decision based on how complex and electronic my cockpit was, and how much I needed/wanted to keep that area dust-free.

My vote is Yes on glass for the windows that are FLAT (turret windows), but "your call" on windows that are curved (nosecone). My theory is that flat windows will photograph well, curved ones will not. But if it were me, I'd also make the decision based on how complex and electronic my cockpit was, and how much I needed/wanted to keep that area dust-free.

TazMan2000

Master Member

The studio model had no glass to prevent reflections while filming. Unless you are planning on using a blue/green screen on this, I think it should contain glass.

TazMan2000

TazMan2000

wow ! lookin really nice

whats the number of louvres per inch on the Smartlouvre?

whats the number of louvres per inch on the Smartlouvre?

wow ! lookin really nice

whats the number of louvres per inch on the Smartlouvre?

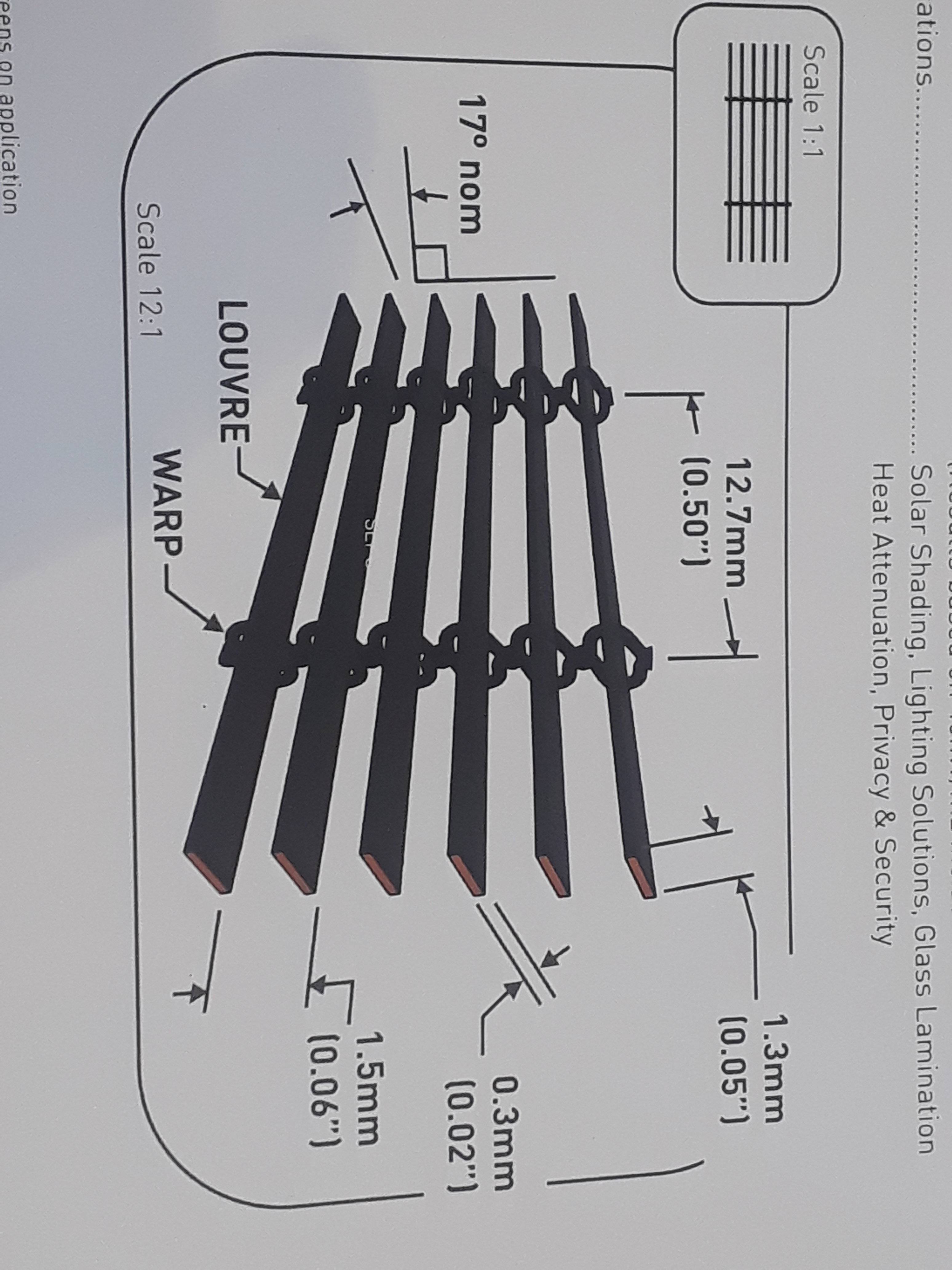

Thanks...slats per inch is 17. I spoke to the guy at Smartlouvre and he is well aware of the Star Wars application of their product. Apparently they still use the same machines that made the original 23 slats per sq. inch but they are no longer calibrated for that and don't produce it. It is bronze with a polyester powder coat instead of the old electrolysis process that they used back in the day

Bjorn

Sr Member

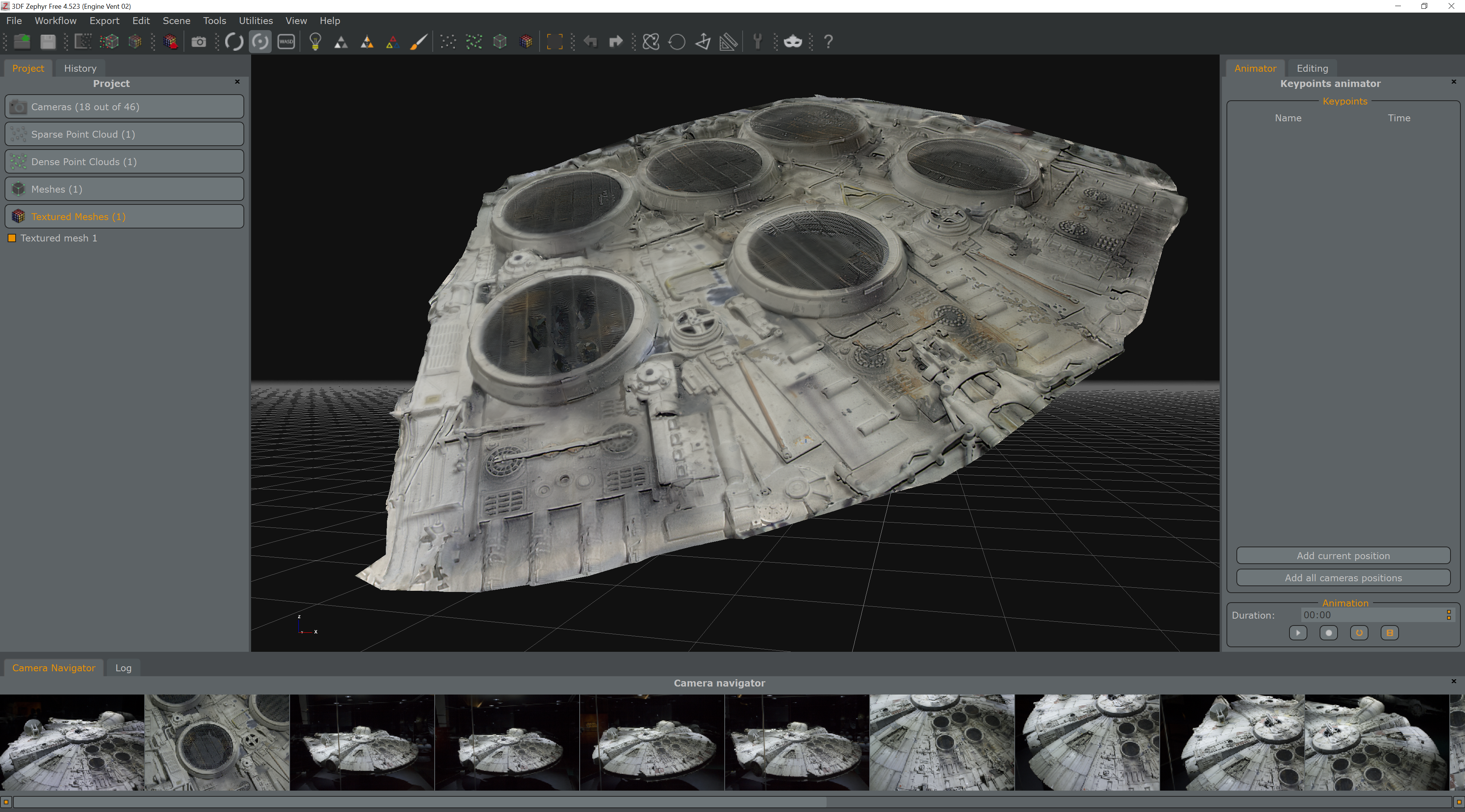

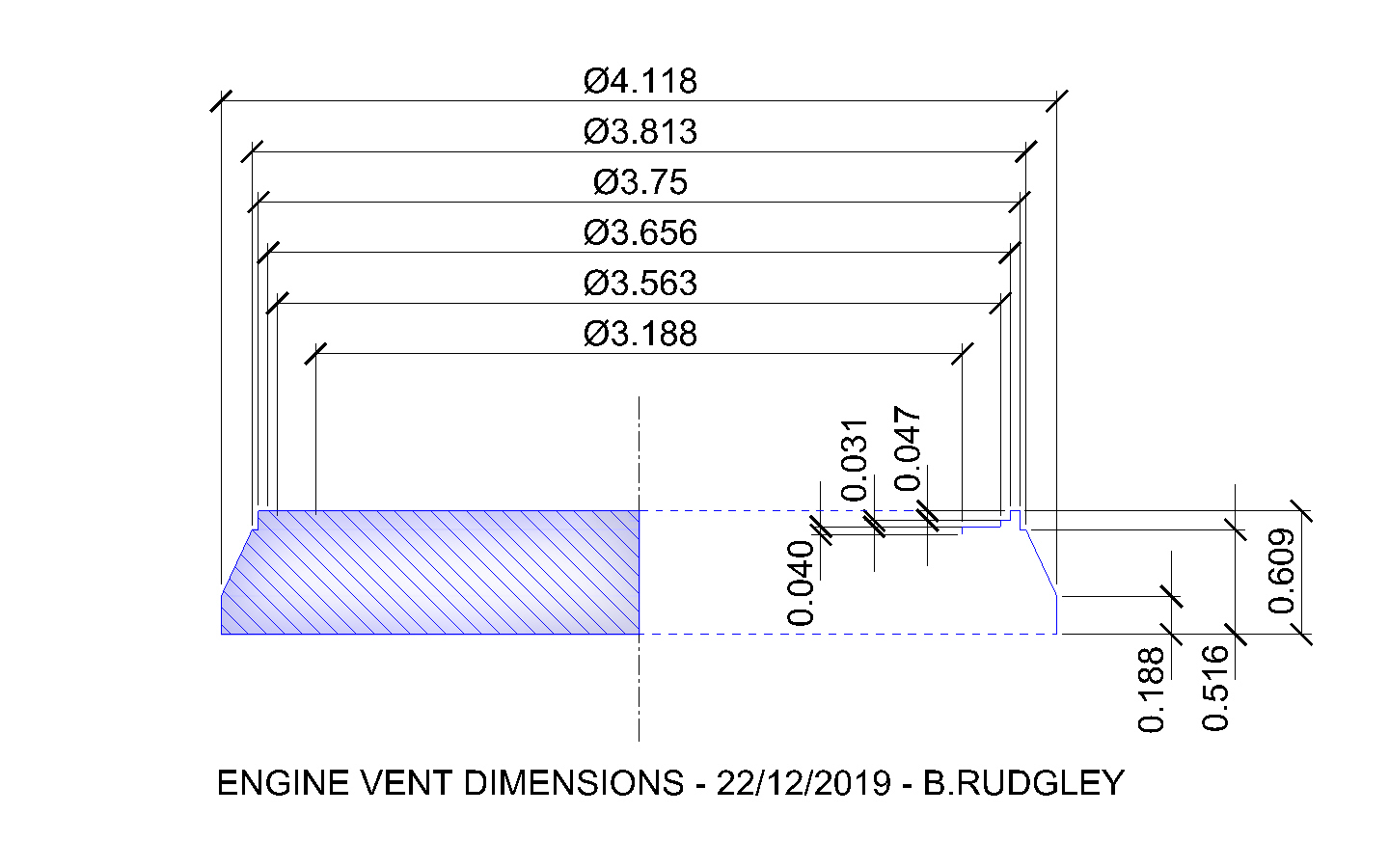

I don't mean to derail this thread but; I was thinking of Vent size recently and decided to try and determine the general dimensions through photogrammetry. Probably a little late for this build but this may benefit others here.

Given I had already modelled the Panther deck in CAD, and using as many decent photos that I could find of the vents, I pulled what I would consider a rough but still fairly reasonable solve by matching the result to the Panther part as best as possible.

(Above) photogrammetry solve using available pictures.

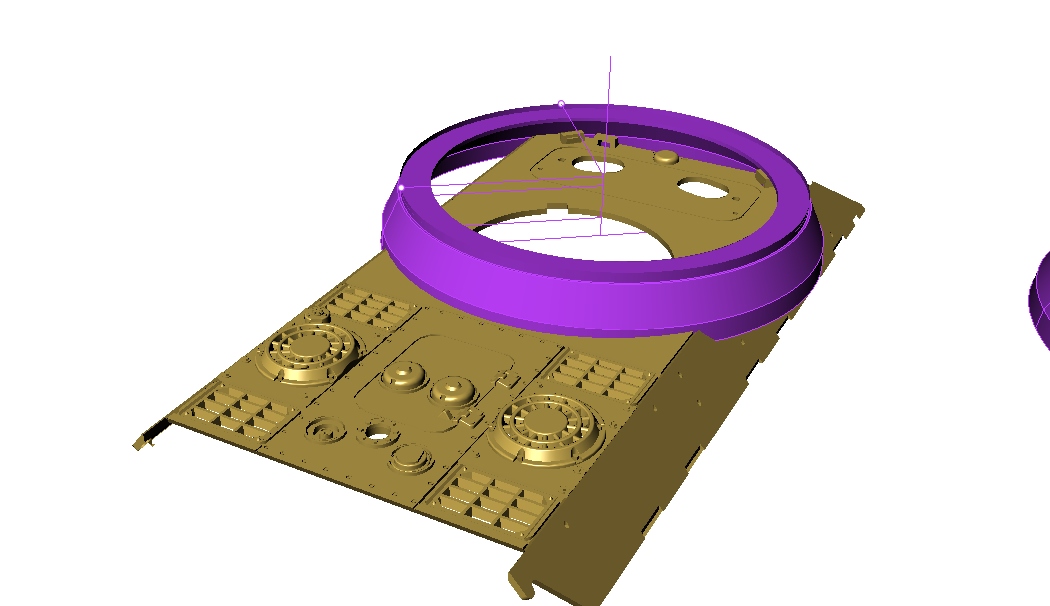

(Above) Panther upper deck CAD model, with early vent geometry derived from result.

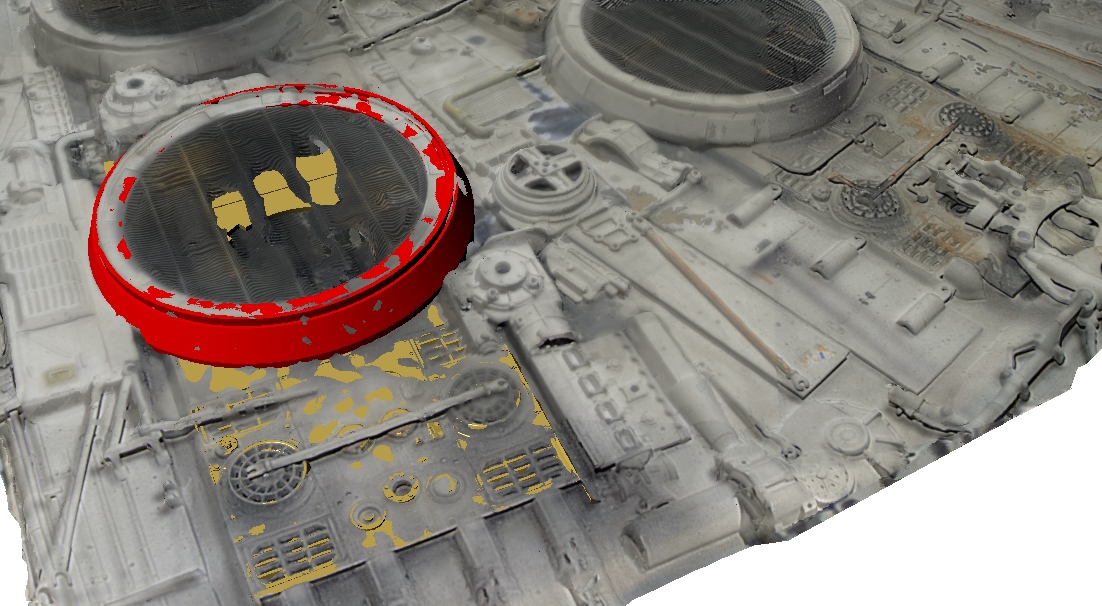

(Above) Final vent model and panther deck aligned to result in CAD.

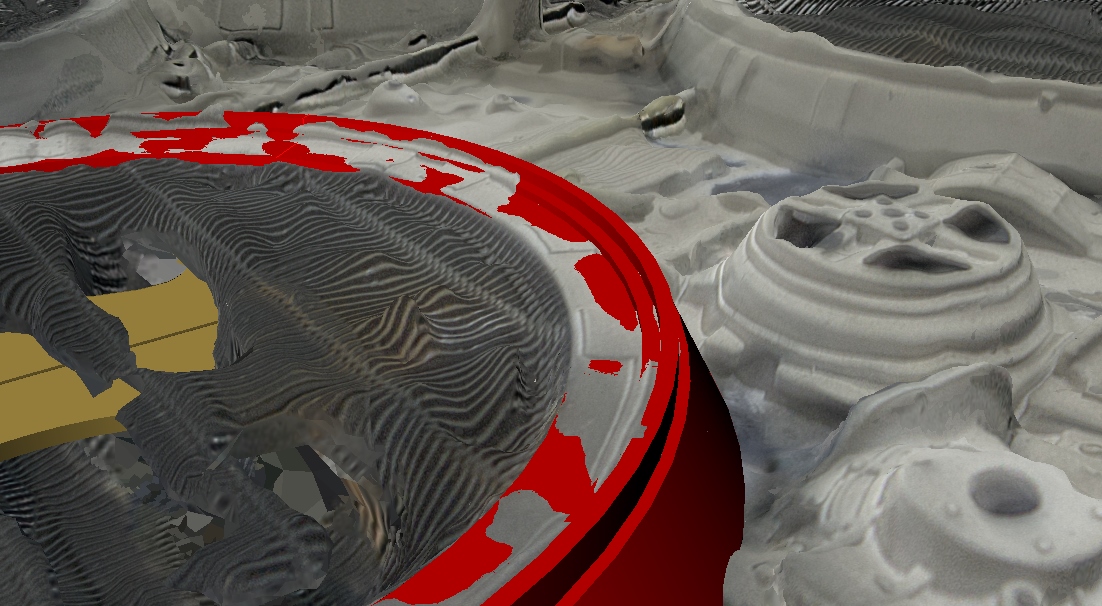

(Above) Closeup of the top lip of the vent.

Interestingly the top outer rim seems to be close to if not 3.75" exactly. Hence in most instances I have rounded to imperial fractions given that it was most likely drawn from these. Maybe...

The top lip seems straight with no taper. The middle chamfer is at approximately 25 degrees, and the lower section I originally thought was angled outward but I have decided that it is most likely vertical and probably turned parallel on a lathe if not found from a kit....

The opening exposing the koolshade has an inner diameter of 3.188". This top cover disc which holds the koolshade in place I have modelled at 0.040" or 1mm.

It goes without saying that I would be curious as to what others have determined for the size of these pieces but hopefully I think this is a good starting point.

end of rant...

Bjorn

EDIT: After much research and new photogrammetry solves I feel these dimensions shown above are oversize in both diameter and height. Eagle1's OD of 4" is more accurate if not spot on. More to follow...

Given I had already modelled the Panther deck in CAD, and using as many decent photos that I could find of the vents, I pulled what I would consider a rough but still fairly reasonable solve by matching the result to the Panther part as best as possible.

(Above) photogrammetry solve using available pictures.

(Above) Panther upper deck CAD model, with early vent geometry derived from result.

(Above) Final vent model and panther deck aligned to result in CAD.

(Above) Closeup of the top lip of the vent.

Interestingly the top outer rim seems to be close to if not 3.75" exactly. Hence in most instances I have rounded to imperial fractions given that it was most likely drawn from these. Maybe...

The top lip seems straight with no taper. The middle chamfer is at approximately 25 degrees, and the lower section I originally thought was angled outward but I have decided that it is most likely vertical and probably turned parallel on a lathe if not found from a kit....

The opening exposing the koolshade has an inner diameter of 3.188". This top cover disc which holds the koolshade in place I have modelled at 0.040" or 1mm.

It goes without saying that I would be curious as to what others have determined for the size of these pieces but hopefully I think this is a good starting point.

end of rant...

Bjorn

EDIT: After much research and new photogrammetry solves I feel these dimensions shown above are oversize in both diameter and height. Eagle1's OD of 4" is more accurate if not spot on. More to follow...

Last edited:

Thanks -- this is hugely helpful! I had 3.25" as my I.D. for the rings, so this is pretty close, and I think I'm leaning more towards your slightly smaller number. (And I may have just been romantically attached to 3.25" b/c that's the I.D. of the inner sub-surface rings of the mandible pits.)

Also, FYI, the vintage Koolshade is exactly 1.18mm in depth, and this is the same depth for the Smartlouvre product still on the market.

Read

Also, FYI, the vintage Koolshade is exactly 1.18mm in depth, and this is the same depth for the Smartlouvre product still on the market.

Read

Bjorn

Sr Member

That's good to know Kitbash regarding the Smartlouvre, given I'm a relative newcomer to this exercise I don't have any original material to reference and was also wondering what the overall thickness was.

Do you have a measurement for the brass ribbon or the wires used in the material. Despite it being really fragile, I would like to see if it is possible to create my own at some stage. Probably a tad ambitious but otherwise, I will likely go with the new material.

Cheers,

Do you have a measurement for the brass ribbon or the wires used in the material. Despite it being really fragile, I would like to see if it is possible to create my own at some stage. Probably a tad ambitious but otherwise, I will likely go with the new material.

Cheers,

Awesome work Bjorn. I think I'm pretty close with my final iteration. Stu, (Eagle1) has given me his dims for the vent rings he made and that Sean also used on his build and they are; OD base 4"/101.6mm. Height 0.511"/13mm. OD top 3.66"/93mm The Top Ring is 3.62"/92mm and Height 0.88/2.25mm. So all in the same ball park but not exactly congruent. Does anyone know where the original vent rings came from...kit part/plastruct/found object?

In the Smartlouvre technical brochure it lists the overall depth as 1.5mm. The actual slats are 1.3mm wide and 0.3mm thick. Here's a pic from the brochure if that helps;

It's beautiful stuff and very strong. I had a few goes at printing these parts in resin and ABS but they don't come close to this product

In the Smartlouvre technical brochure it lists the overall depth as 1.5mm. The actual slats are 1.3mm wide and 0.3mm thick. Here's a pic from the brochure if that helps;

It's beautiful stuff and very strong. I had a few goes at printing these parts in resin and ABS but they don't come close to this product

Similar threads

- Replies

- 11

- Views

- 1,099

- Replies

- 3

- Views

- 541

- Replies

- 18

- Views

- 5,712