SwampDonkey

Well-Known Member

Yo Marty! I sent you an email a week or so ago; let me know if you didn't get it and I'll resend it. Following this thread with GREAT interest!!

Hey, man!

Yeah send it again if you would. Ive been using my work email so much the old one gets neglected. With any luck I'll have access to a CNC machine here pretty soon so it may be full aluminum kits for RPF members at some point:thumbsup

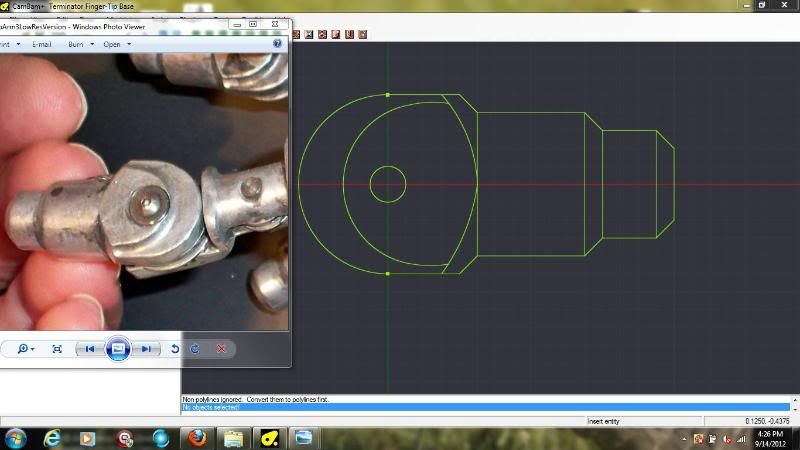

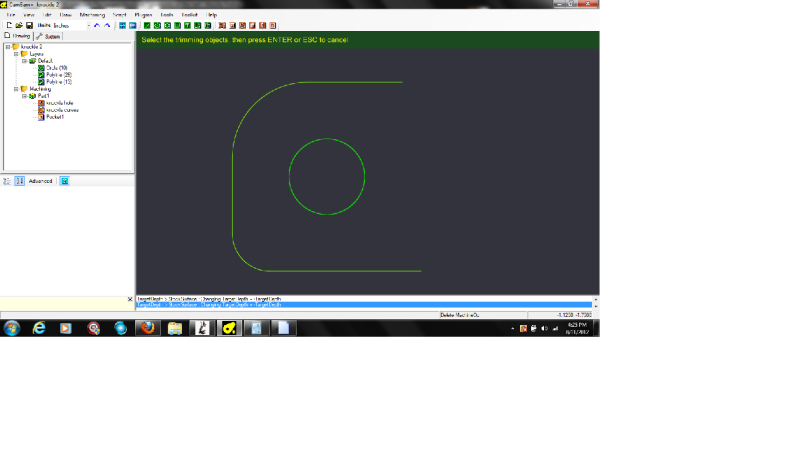

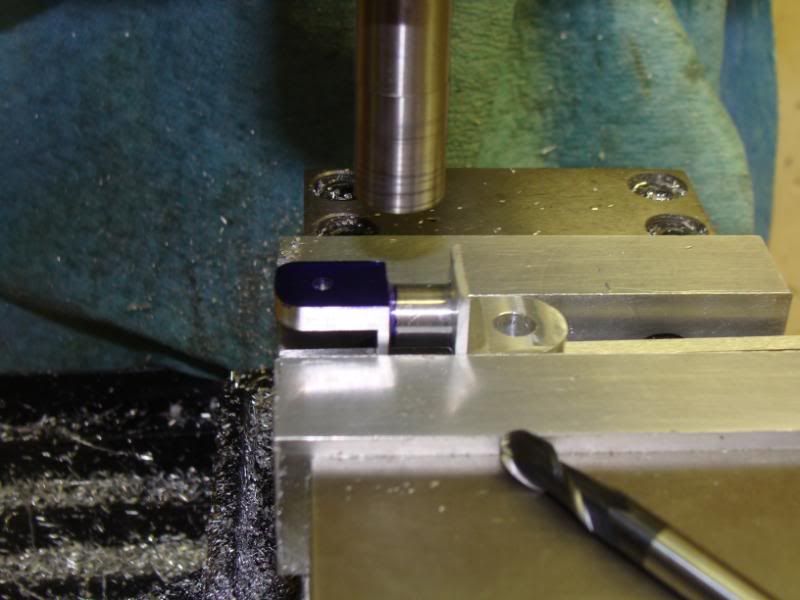

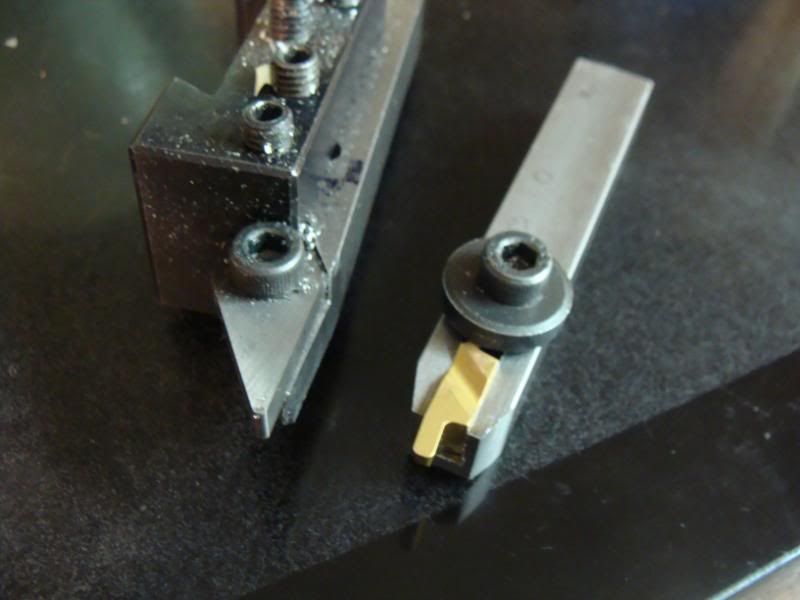

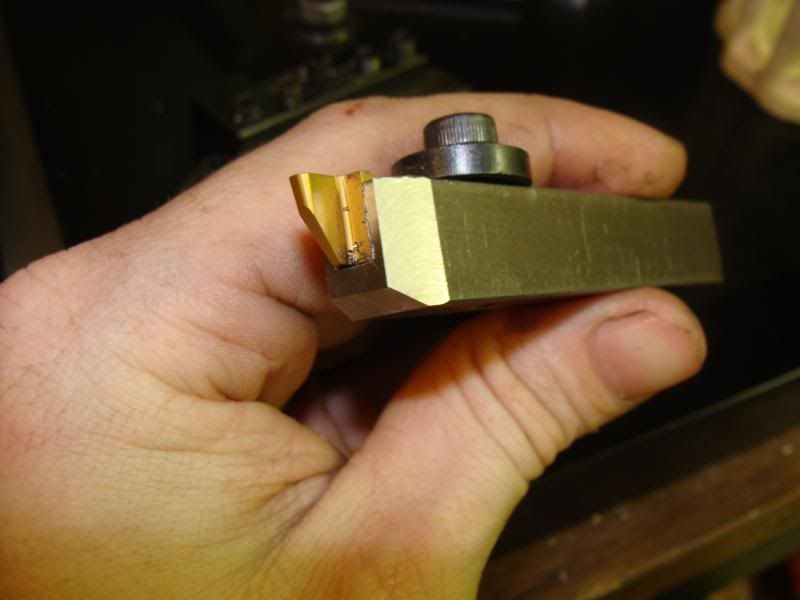

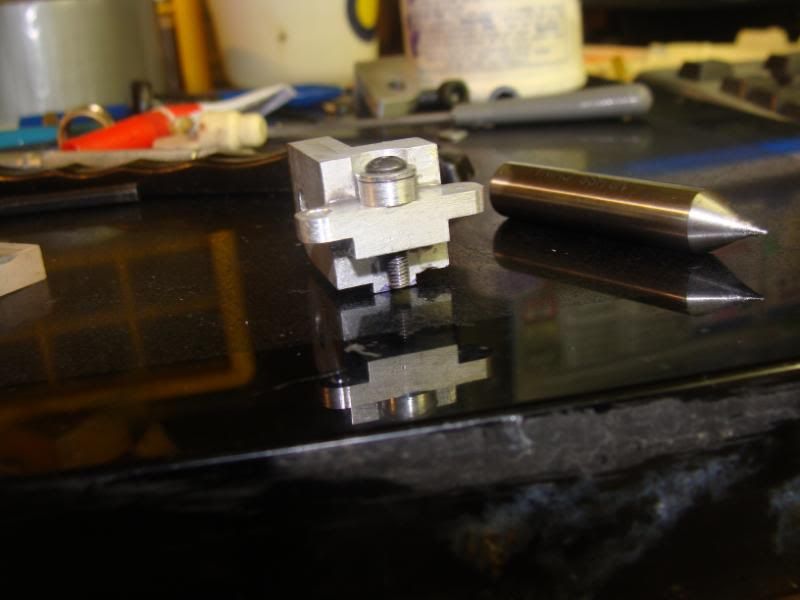

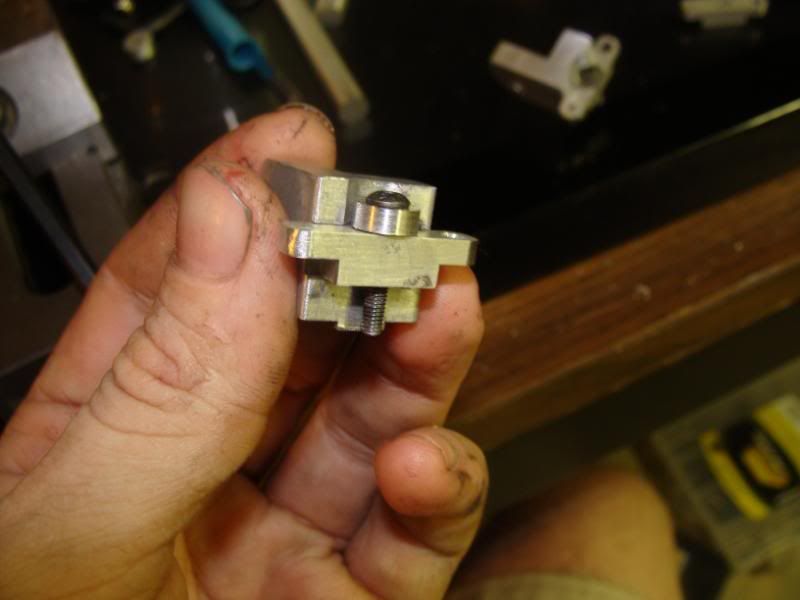

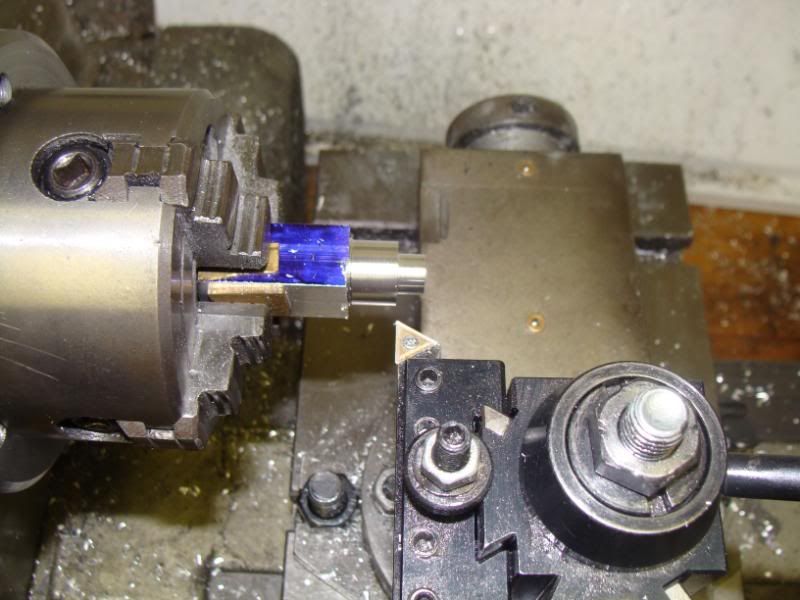

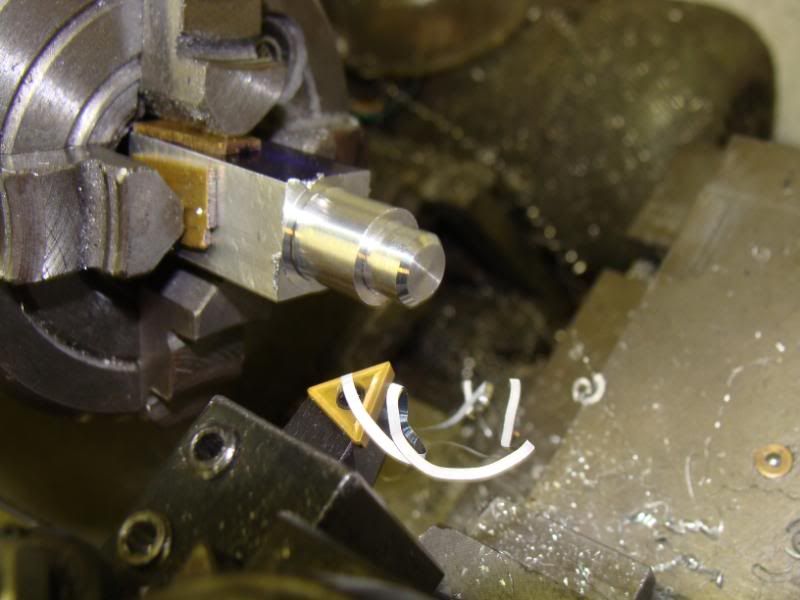

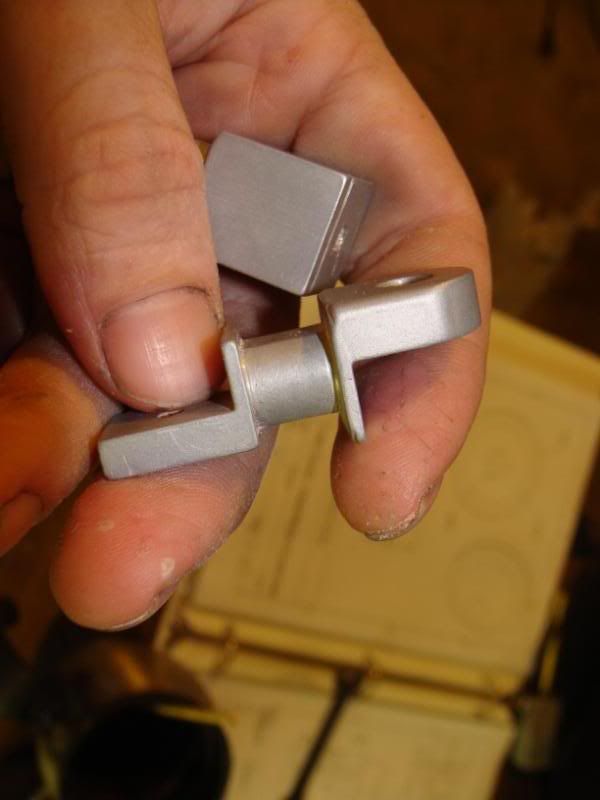

For now I'm tweaking out the details and getting the process down. The parts in the pic are V3.0 (in other words, I screwed up 2 versions so far). The "large" sections that make up the finger between the 1st and 2nd knuckle are being redone since im convinced I milled the slots 1/16 too wide. All together I have about 30 finished parts.

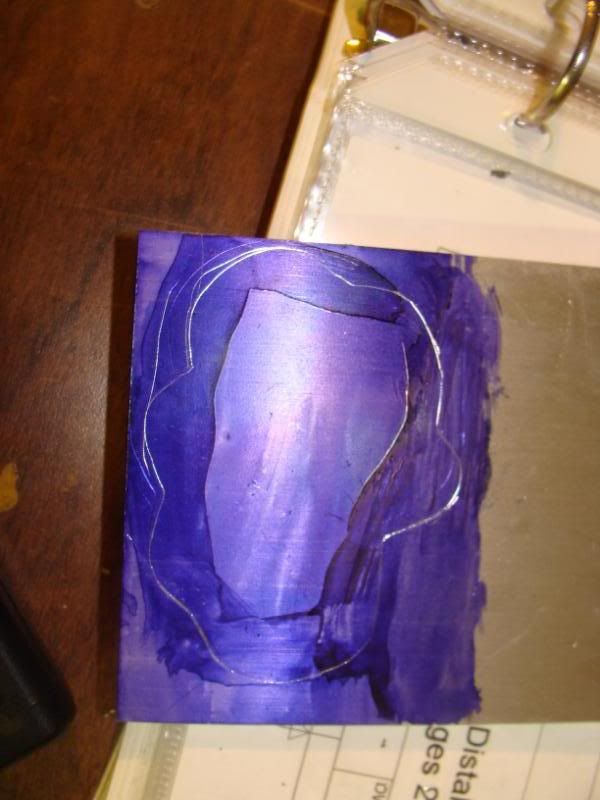

There's been a lot of this process:

-Make the part based on research and "info"

-Compare it to all available reference

-Notice it looks off from one particular angle

-Remake the part with alterations

-Say "Eureka! So thats what they did"

- Move on to next part, or part of the same part and likely notice something else and have to start over again anyway.

But thats how it goes I guess:cool

You said something about kits. How much do thin none will end up?

Yup, the master (in the pics) is spoken for and...not cheap

BUT WAIT!

There will be kits available once everything is done. I'll head over to the JY thread and go into more detail here soon. PM for details.