helix_3

Well-Known Member

I have a lot of MMS and I'm low on Mold Star. If I run out of MS, can I use MMS as a regular pourable mold rubber? I know MMS is tin cure (not a problem) and thicker than Mold Star (also fine, I'll be pressure casting).

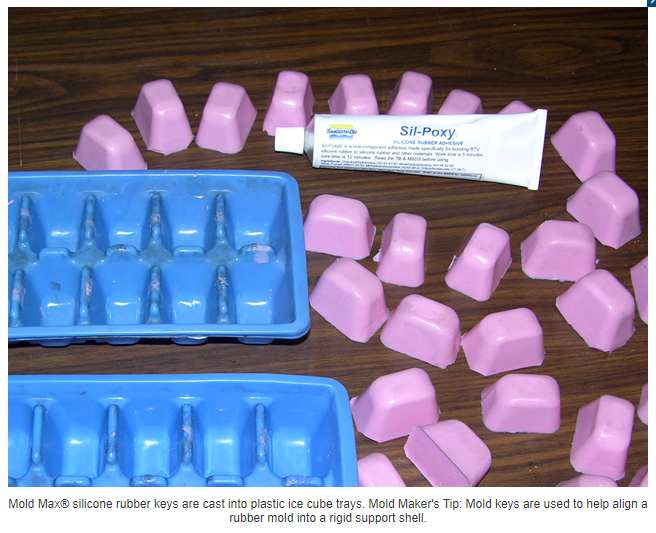

The TDS doesn't address this, but this tutorial from Smooth-On would imply it's possible. But I'm not totally sure, since rubber keys can be a little off and still work. I need good surface finish, etc.

Does anyone have experience with this?

The TDS doesn't address this, but this tutorial from Smooth-On would imply it's possible. But I'm not totally sure, since rubber keys can be a little off and still work. I need good surface finish, etc.

Does anyone have experience with this?