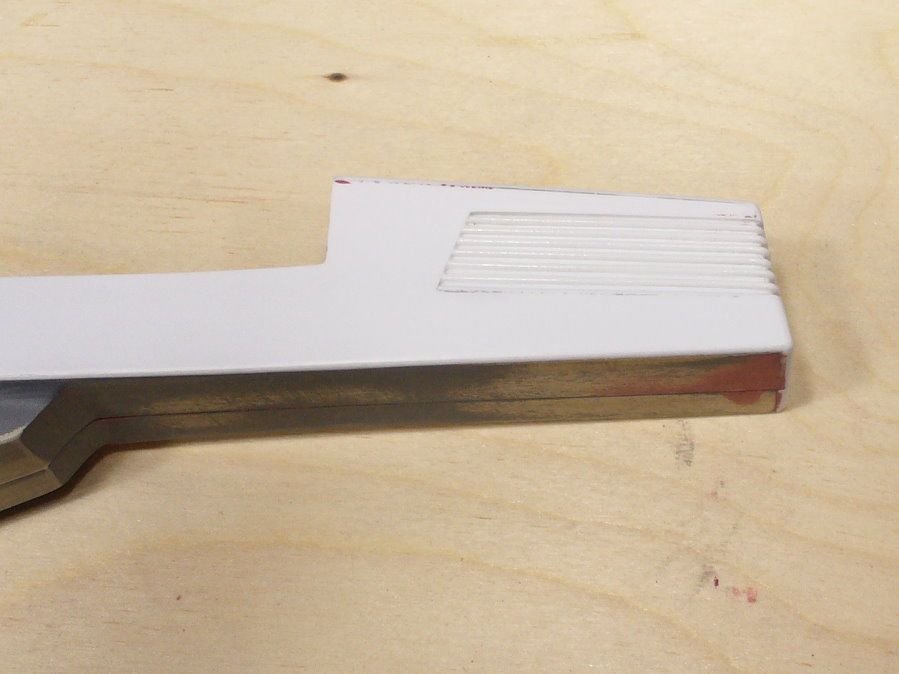

I've done the final shaping on the P2, rounding over the edges.

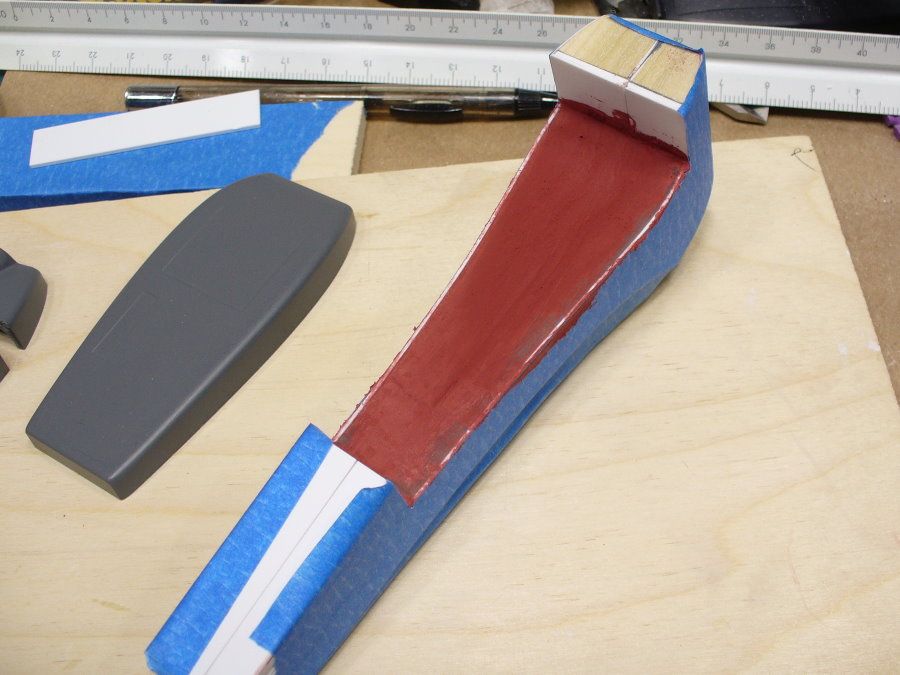

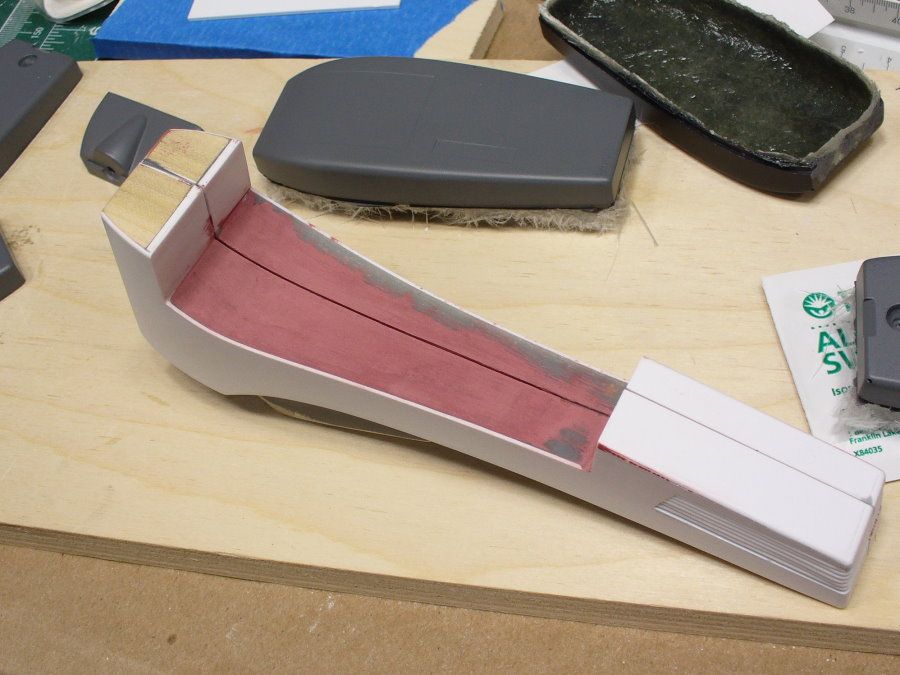

I then added filler to even out the P1 slot. I taped the two halves together to make sure they match.

After sanding I had to cut through the filler to separate them.

I then added a skin of thin styrene, I'll have pics when it's trimmed up.

On to the P1, I was hoping that the Watertrap would allow me to use resin as a gelcoat. But it still foams up a little bit. It seems to work okay in a closed mold like the bezel, but not in an open mold like the P1. The black P1 in the above pic is one of the bad casts. So I went back to painting the mold and using epoxy based gelcoat. Here's the first set.

Perfect fit, even better than the first ones.

Second set. Both sets have a few pin holes but not bad.

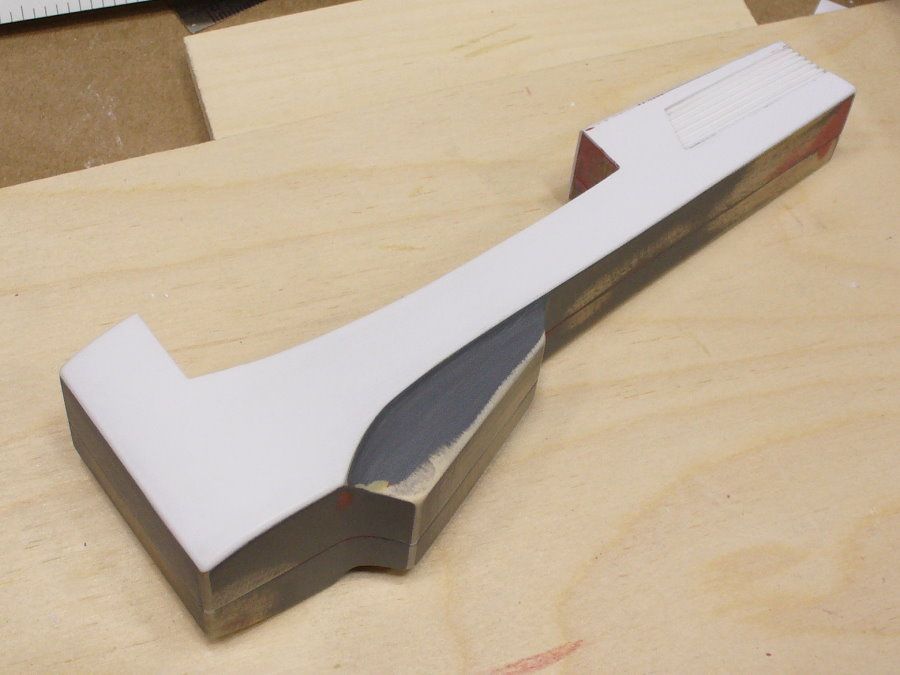

While waiting on primer and filler to dry, I started on the handle. My attempt to bend the brass tube was a dismal failure. I don't want to waste any more time or money on it, so I started a buck for a glass handle. I shaped it in wood and primered it.

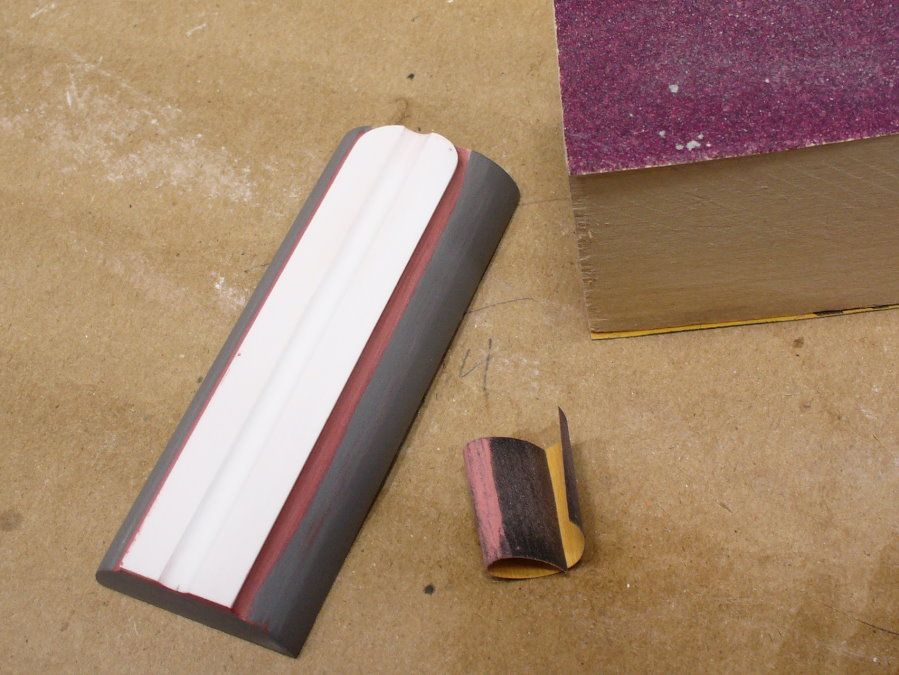

Made the grip with styrene strips, then used a 1/4in rat tail file to shape the center groove. Glued it to the wood then blended in with filler.

Sanded the filler with rolled sand paper.

Here it is with the final primer coat.

It now has the final paint coat and is ready to mold. I'll make two molds of the one half and cast two copies.