crackerjazz

Sr Member

Thanks, Amish Trooper. Jefifye, thanks. You have a good point there heheh. The MR is a model of the 32-inch ESB version though, and I'm after the 5-footer version.

Recently, I just figured something out. With the Hasbro degutted, the hull is actually slightly flexible. Need less dome? Push the hulls together at the top and bottom very slightly and you get the 32-inch dome shape. Better yet, cut off the landing gear boxes completely before you do that.

Find a way to fix the shape in place from inside and you're off to a good start.

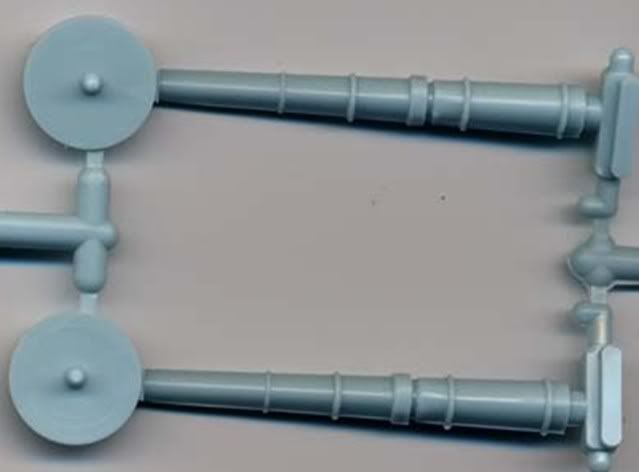

So for those who have the Hasbro and are thinking of building a 32-inch model out of it, some details are actually pretty good already. Slim the sidewalls (not by as much as the 5-footer's of course) and mandibles, cut the mandibles and toe them in, cut a bit off the jawboxes, rebuild the cockpit and tunnel, rebuild the landing gear boxes, and scratchbuild the sidewall and mandible details. You can leave a lot of things alone -most of the rear panel details, the piping, the rear underside panel details, the docking arms and rings - I have to modify all of those.

Of course, the wizards over at the studio scale forums might soon come up with a kit form of the 32-inch ESB version so it might be a better idea to just wait.

Recently, I just figured something out. With the Hasbro degutted, the hull is actually slightly flexible. Need less dome? Push the hulls together at the top and bottom very slightly and you get the 32-inch dome shape. Better yet, cut off the landing gear boxes completely before you do that.

Find a way to fix the shape in place from inside and you're off to a good start.

So for those who have the Hasbro and are thinking of building a 32-inch model out of it, some details are actually pretty good already. Slim the sidewalls (not by as much as the 5-footer's of course) and mandibles, cut the mandibles and toe them in, cut a bit off the jawboxes, rebuild the cockpit and tunnel, rebuild the landing gear boxes, and scratchbuild the sidewall and mandible details. You can leave a lot of things alone -most of the rear panel details, the piping, the rear underside panel details, the docking arms and rings - I have to modify all of those.

Of course, the wizards over at the studio scale forums might soon come up with a kit form of the 32-inch ESB version so it might be a better idea to just wait.

Last edited: