You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Halliwax's weird V3 theory

- Thread starter Halliwax

- Start date

Right place at the right time! Story of my life this year.Well done! Great detective work BRRogers.

I was wondering if the original wooden master is probably a tad larger than the hero lightsaber because of the shrinking factor of the aluminum?Right place at the right time! Story of my life this year.

Well, going off the propstore ruler photos…

I had my MK1 handwheel turned ONLY out a few threads (the assembly I have won’t let it go farther at the moment)

It seems like the handwheel on the original wooden buck would indicate it was unthreaded about 1/4”ish further than what I managed.

Those numbers translate onto the ruler (11-1/4” length in the propstore buck) visually matches what I’ve got here sans the pommel which is too close to the booster. (Mine hits at 11” right now)

Dimensionally, that would indicate to me that the shrinkage wasn’t majorly significant with the metal casting… just that the buck was longer than the final stunt assemblies

Also worth noting..

the windvane /balance pipe and forward pommel areas would have required the most creative reshaping on the original… and given what I have those are two areas I messed up in this regard… the variance here however makes more sense to me now- I’m more and more convinced.

If I were to do it again I would move

The windvane up towards the Balance pipe and try to get more length from the pommel. All of the required material off the MK1 to make the wooden blank as it was would then be there- and more interestingly, would make complete sense

Last edited:

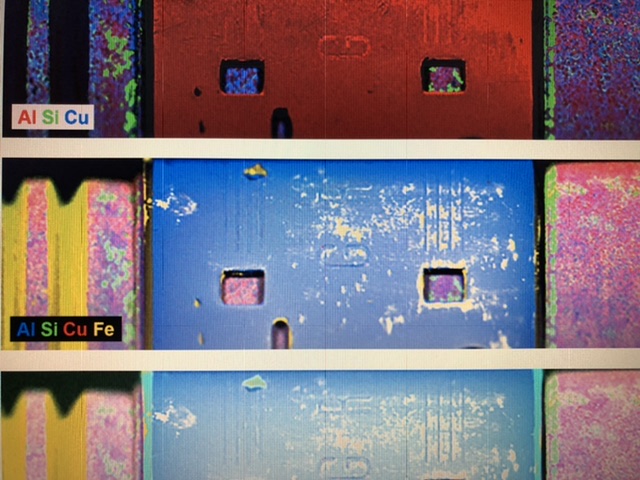

Wow, that‘s really fascinating. A few weeks ago, I had the metal alloy of my original blank analyzed via X-ray fluorescence analysis, but that‘s stuff for a whole new thread.View attachment 1517502

Well, going off the propstore ruler photos…

I had my MK1 handwheel turned ONLY out a few threads (the assembly I have won’t let it go farther at the moment)

It seems like the handwheel on the original wooden buck would indicate it was unthreaded about 1/4”ish further than what I managed.

Those numbers translate onto the ruler (11-1/4” length in the propstore buck) visually matches what I’ve got here sans the pommel which is too close to the booster. (Mine hits at 11” right now)

Dimensionally, that would indicate to me that the shrinkage wasn’t majorly significant with the metal casting… just that the buck was longer than the final stunt assemblies

View attachment 1517503

...Dimensionally, that would indicate to me that the shrinkage wasn’t majorly significant with the metal casting… just that the buck was longer than the final stunt assemblies...

This I can verify. All of the shrinkage from what I've done really comes from the type of metal cooked up to cast the hilts. Casting alu shrinks the least, ~6% of surface area, from what I've used, but extruded shrinks the absolute most, ~10%. The bottom of the booster also gets some meat cut off on the V2 and V3..

Wow, that‘s really fascinating. A few weeks ago, I had the metal alloy of my original blank analyzed via X-ray fluorescence analysis, but that‘s stuff for a whole new thread.

Please let us know!

Last edited:

Our fellow RPF’ler LOM brought me in touch with some scientists at the Museum für Naturkunde here in Berlin. They normally analyze the composition of meteorites. We told them about my blank and what it was made for, and they agreed to examine it in order to determine the exact aluminum alloy that was used to produce the lightsaber blanks. I‘m going to bump Nathan to post the results in this thread.

Here is a little teaser pic from the analysis. I‘d really like to wait with the publishing of the exact metallic components of the blank until LOM chimes in, he had the idea of doing this and arranged the meeting.

Just from the teaser pic, it looks to be shaping up as casting Alu. This is from the technical datasheet I have on the stuff I buy (a356 and a356.2), composition of casting aluminium is:

This along with the work BRRogers has done leads me to believe the making of these hilts weren't done by the guys at Elstree at all. This sounds more and more like the work the guys who made the parts for R2 had done. Could they have made the buck in-house since they may have had the Obi Hero on hand and had the hilts forged at a foundry somewhere else? Was it easy to get casting alu then?

Aluminum, Al 91.3 - 93.2 % 91.3 - 93.2 % As remainder Copper, Cu <= 0.10 % <= 0.10 % Iron, Fe <= 0.12 % <= 0.12 % Magnesium, Mg 0.30 - 0.45 % 0.30 - 0.45 % Manganese, Mn <= 0.05 % <= 0.05 % Other, each <= 0.05 % <= 0.05 % Other, total <= 0.15 % <= 0.15 % Silicon, Si 6.5 - 7.5 % 6.5 - 7.5 % Titanium, Ti <= 0.20 % <= 0.20 % Zinc, Zn <= 0.05 % <= 0.05 %

This along with the work BRRogers has done leads me to believe the making of these hilts weren't done by the guys at Elstree at all. This sounds more and more like the work the guys who made the parts for R2 had done. Could they have made the buck in-house since they may have had the Obi Hero on hand and had the hilts forged at a foundry somewhere else? Was it easy to get casting alu then?

Last edited:

Not only were the Kenobi stunts cast but many other things, e11 parts, and a few r2 parts

The Bapty E11 for Tunisia had some cast parts, R2 in that thread had arm and leg parts cast, and the Kenobi stunts now...I'm thinking they may have all just come from the same near-by place.

Last edited:

Completely agree with yaThe Bapty E11 for Tunisia had some cast parts, R2 in that thread had arm and leg parts cast, and the Kenobi stunts now...I thinking they may have all just come from the same near-by place.

Similar threads

- Replies

- 1

- Views

- 388

- Replies

- 6

- Views

- 1,066

- Replies

- 146

- Views

- 8,585