joewhite

Sr Member

Julien,

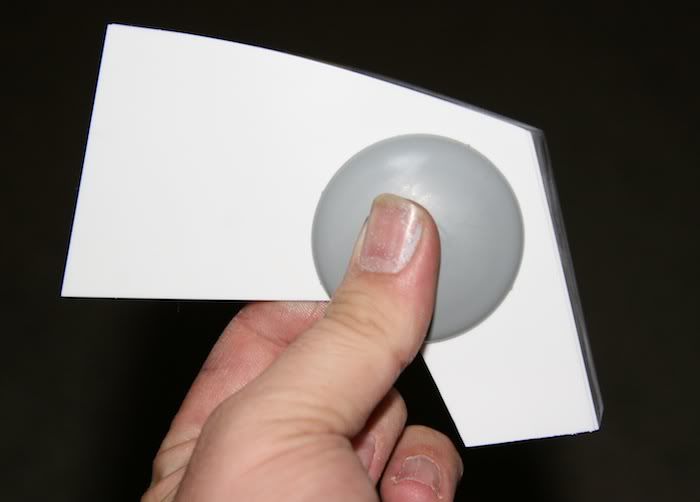

Yeah, these are what mine look like....(pic from StudioScale.com).....I know this only shows one side but both sides look alike. The one on the SS model has that extra circular detail where the dimple is on the second part below.

EDIT: Removed my suspicion of sanded inner sides of Fruehauf parts. Got a better angle of it.

Quincy,

My, bad, I forgot about that part.

Joe

Yeah, these are what mine look like....(pic from StudioScale.com).....I know this only shows one side but both sides look alike. The one on the SS model has that extra circular detail where the dimple is on the second part below.

EDIT: Removed my suspicion of sanded inner sides of Fruehauf parts. Got a better angle of it.

Quincy,

My, bad, I forgot about that part.

Joe

Last edited: