I'm not trying to be argumentative saying this, but I'm not stopping anyone from doing anything.

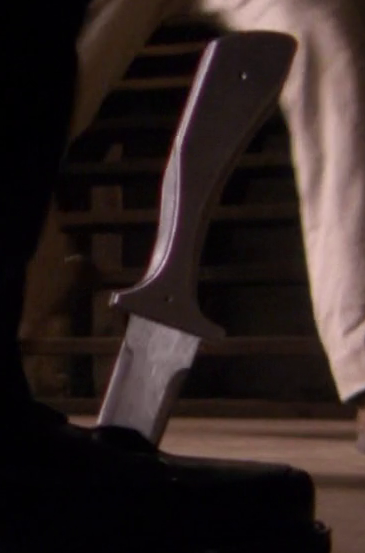

I'm also not happy that I'm being portrayed as doing something wrong. Nick, I don't want to belittle all you've done with this design, but I see this knife as a group design. We've all added our two cents, and the knife is better for it.

I'm not portraying you as doing anything wrong. I simply meant that since much of the collaboration for this occurred through emails, off of this board, and much of it before you were brought on board, it would have been nice to have been asked.

If you had, I would have given my full support, like you have now. I spent all that time designing because I want to see this knife come to fruition so badly. So by all means, do it, and make it incredible!

I really appreciate and respect all that you've put into this project, and thank you for addressing this with me, head on.

So let's get all of that behind us, and see some more knife progress! To my eye, it's looking great so far. Once the finishing is done, this thing is going to look killer!

Can't wait to see this as it comes along.

-Nick

PS: Is that table you're displaying the handle on from Ikea? I think I may have the same one if it is.