Inspired by work in this thread

Many thanks and appreciation to genZOD - for posting the plans in the thread linked above.

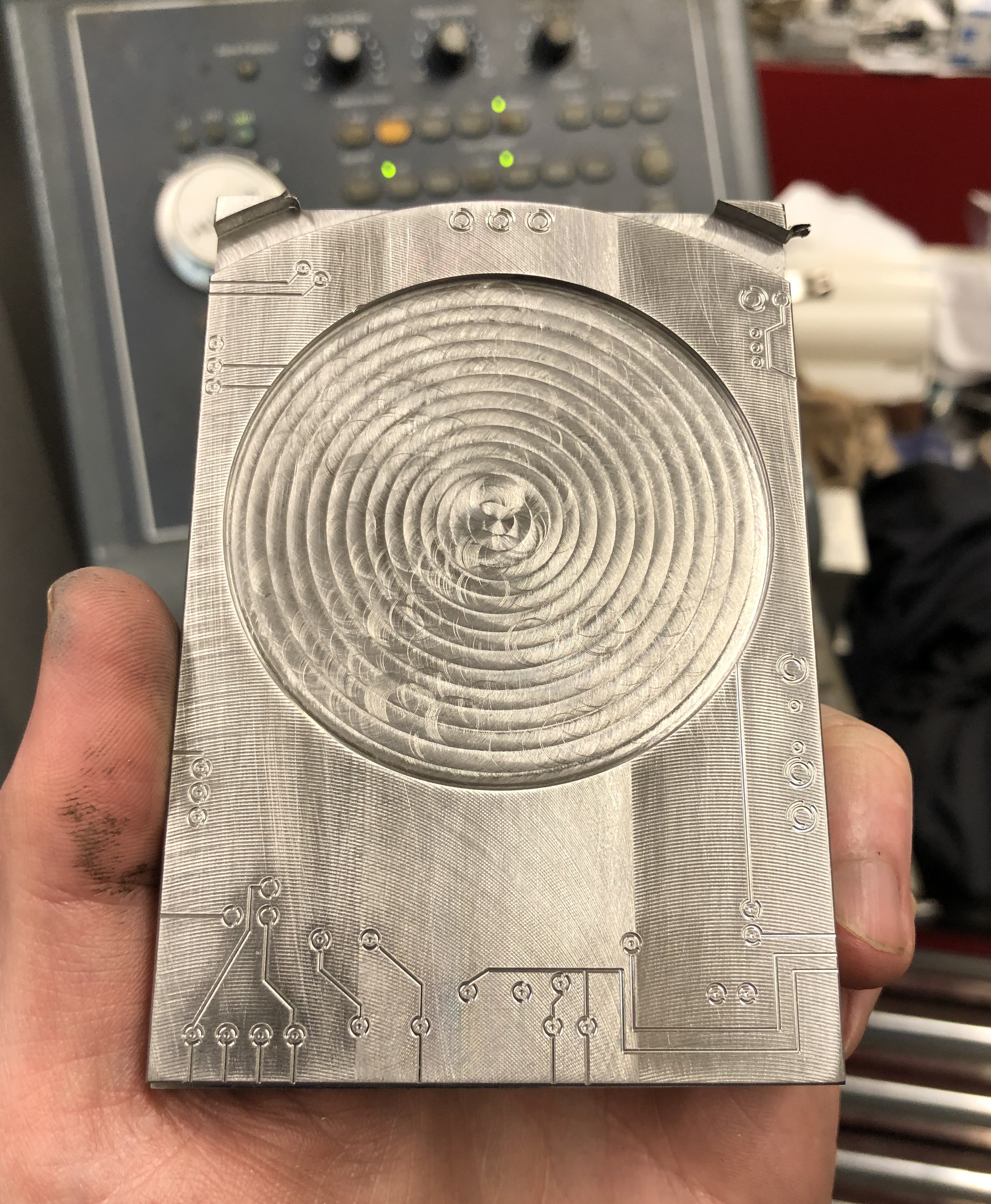

Started work on this, just a test of the engraving, worked well the actual.

Finished piece will come out of ground tool steel, which is very flat and doesn't need machining on the face. Therefore will have a nice even surface finish.

Before and After

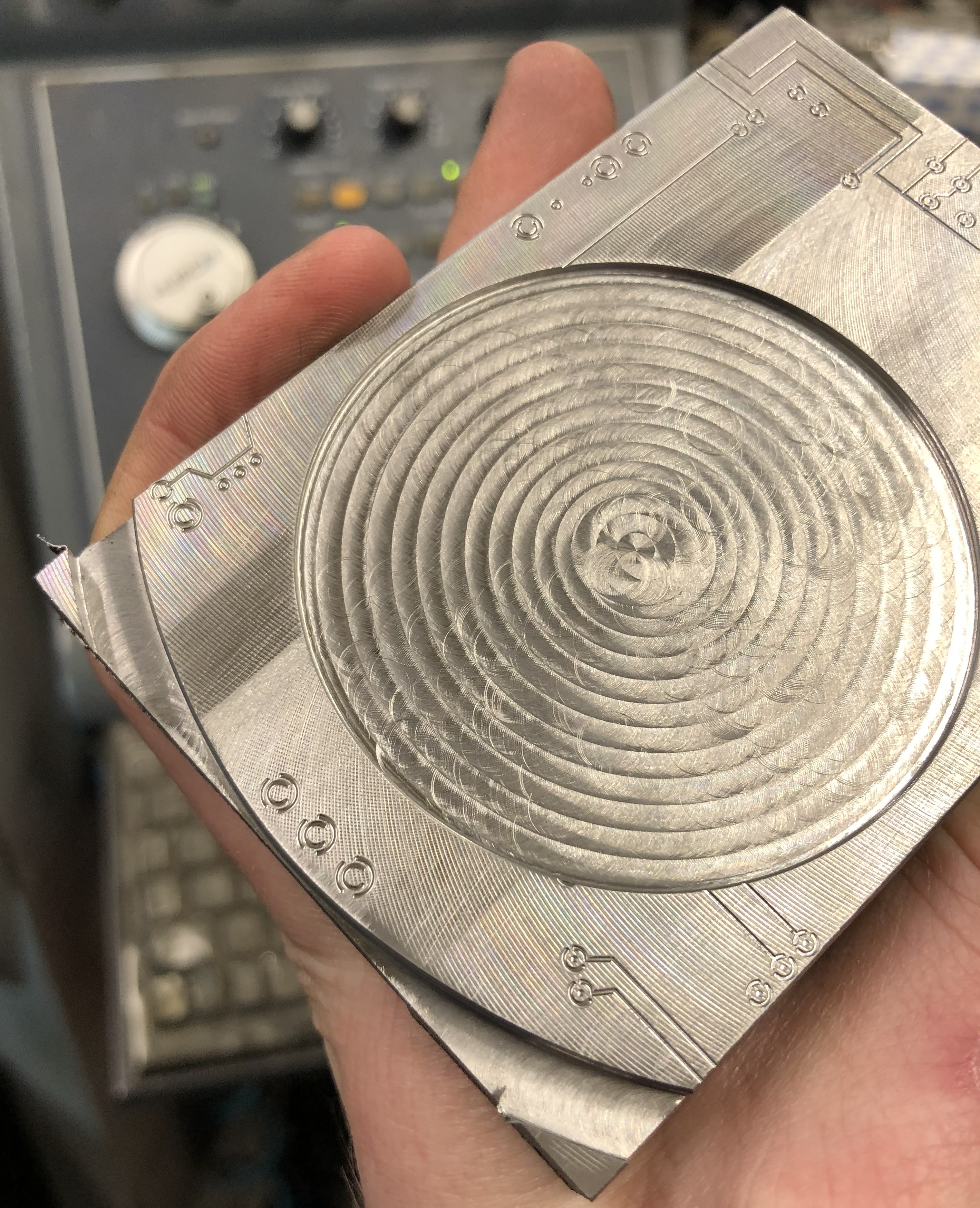

And after cleaning up the burrs.

Many thanks and appreciation to genZOD - for posting the plans in the thread linked above.

Started work on this, just a test of the engraving, worked well the actual.

Finished piece will come out of ground tool steel, which is very flat and doesn't need machining on the face. Therefore will have a nice even surface finish.

Before and After

And after cleaning up the burrs.