NBergmann

New Member

Hello all,

I recently decided to test out a different way to make a Cap shield using a tractor disc. The disc itself is 24" Diameter carbon steel, 1/4" thick, roughly 33lbs, and around 3" concavity. A local farm supply store had them stock, and I was able to have one shipped to me for less than $80.

This is base disc with paint stripped off to fill in the stamps with MIG weld. A rod was welded in the center hole to mount in my turning machine for sanding and grinding.

After ample sanding for a spun look, I have a Dremel mounted to a stand to cut in the rings. Took some trial and error to get consistent cuts, but did manage to end up with some pleasing results.

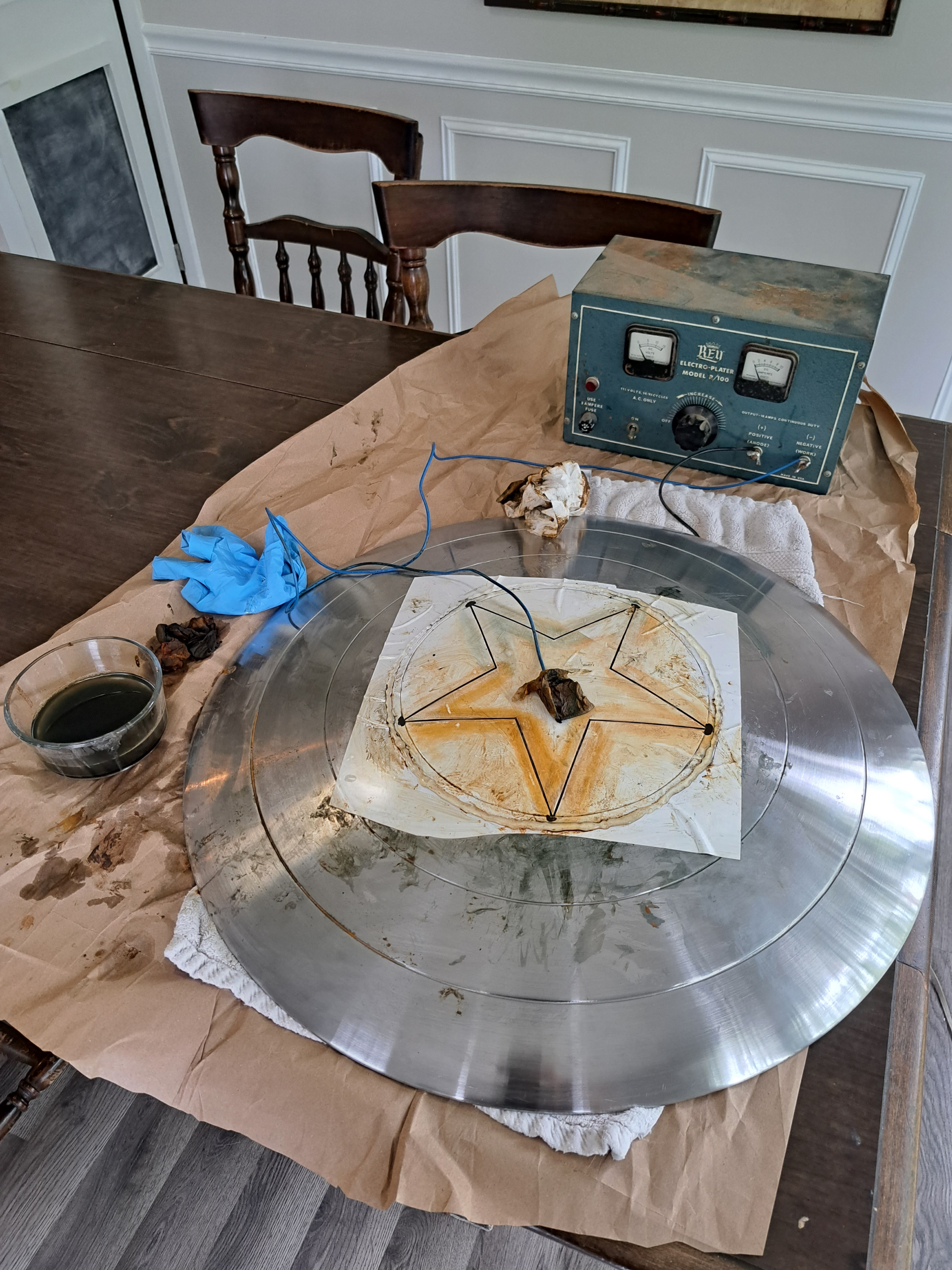

Next up was the star. I know a lot of people mount a cut out star on the surface of aluminum shields, but I wanted a solid piece. I tossed around the idea of using the Dremel for this, but I felt a lot more confident with electro-etching it in (peep the ancient electro-plater). Just used some adhesive vinyl, drew the star in place, and cut out the lines with a utility knife. Hooked up the electrodes and spent some time with an electrolyte solution on a paper towel. Ended up getting a fairly deep etch.

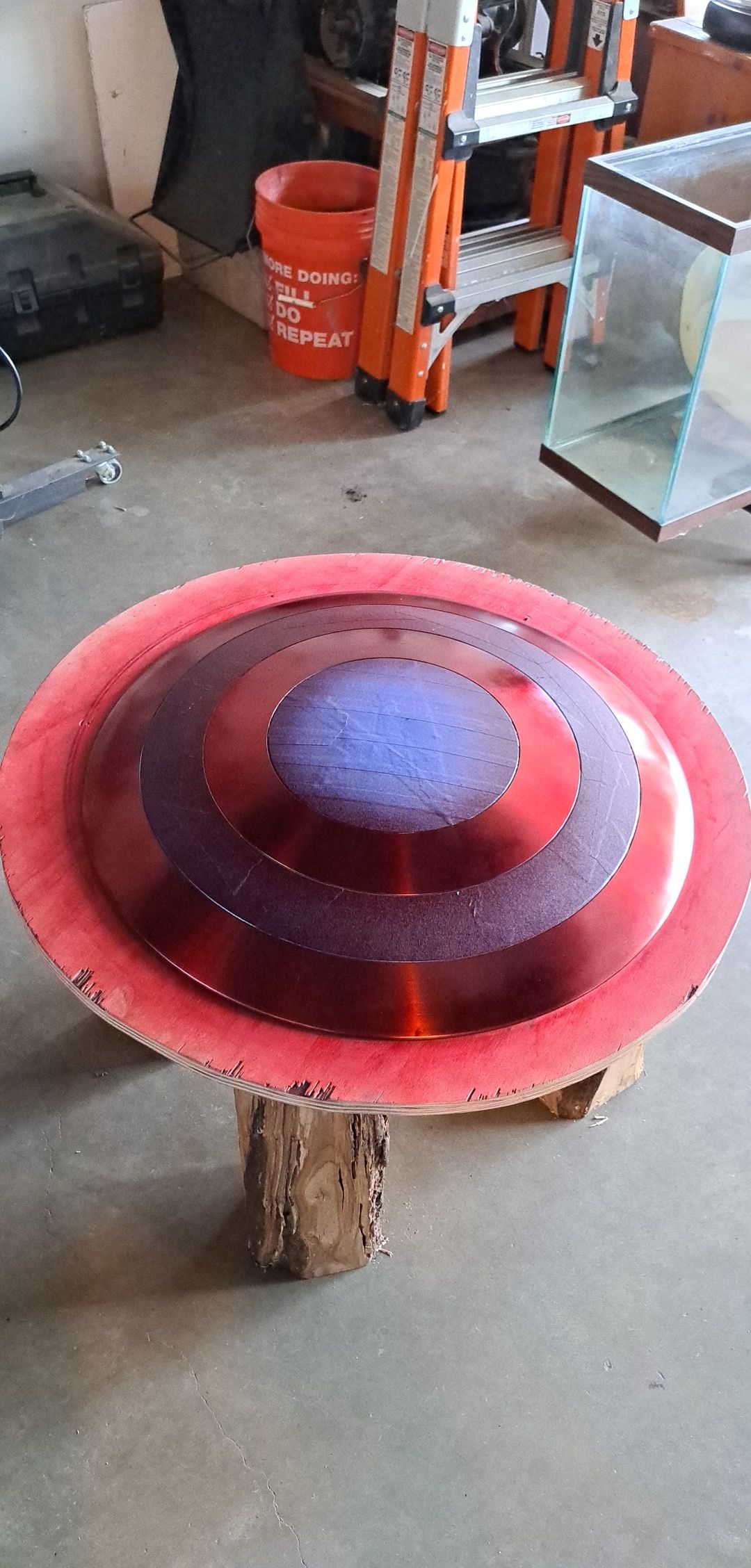

AND here is the result with some black paint sprayed into the cuts. Was really tempted to just leave it here because it looks so clean, but I did soon follow up with paint.

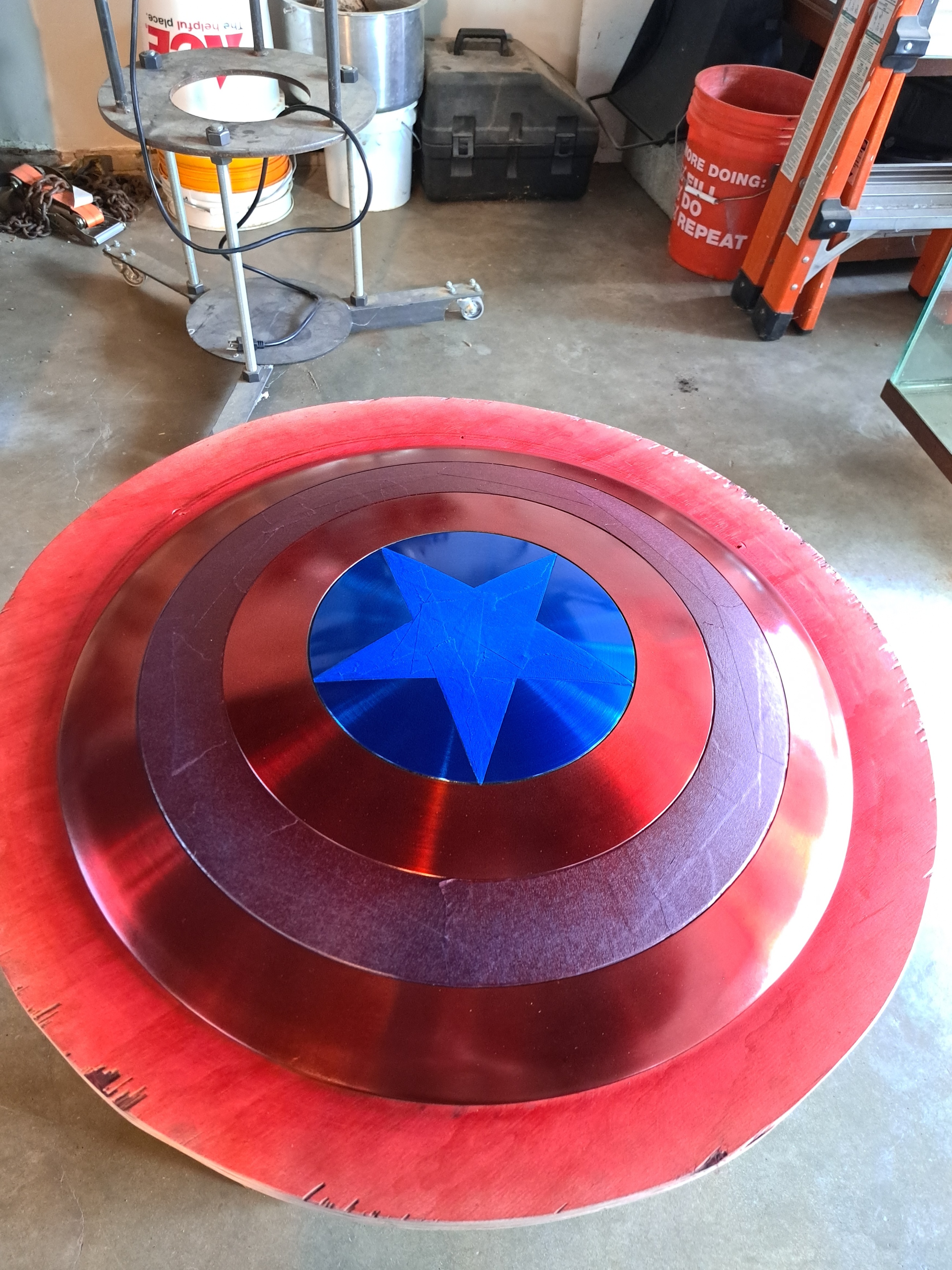

Duplicolor makes a lovely faux anodized enamel paint. Clear enough to see the metal texture, but with enough coats the color really pops. Its not the cleanest application, though. I was a little splotchy with the gloss, but ended up going over everything with steel wool in the end to give it a matte look.

Final shots! Went over everything with a clear enamel to prevent rust and another round of steel wool. Didn't do much with the back of the shield as this ended up being a wedding present and there was a deadline closing in (also forgot to take pictures of the back before giving away). Welded the brackets on earlier in the build and finished up come leather belts for straps.

Very pleased with how it turned out. Lines are clean, colors are great, but it is VERY heavy. Would love to try again with a thinner stainless steel disc, may be able to get ahold of a vessel head fabricator in my line of work, but that will be costly.

Hopefully this project may prove to be useful to any garage builders like myself. I had some tools that made it easier, but anyone with a welder, grinder, and looks into electo-etching could do this from home with some patience. Let me know what you think!

I recently decided to test out a different way to make a Cap shield using a tractor disc. The disc itself is 24" Diameter carbon steel, 1/4" thick, roughly 33lbs, and around 3" concavity. A local farm supply store had them stock, and I was able to have one shipped to me for less than $80.

This is base disc with paint stripped off to fill in the stamps with MIG weld. A rod was welded in the center hole to mount in my turning machine for sanding and grinding.

After ample sanding for a spun look, I have a Dremel mounted to a stand to cut in the rings. Took some trial and error to get consistent cuts, but did manage to end up with some pleasing results.

Next up was the star. I know a lot of people mount a cut out star on the surface of aluminum shields, but I wanted a solid piece. I tossed around the idea of using the Dremel for this, but I felt a lot more confident with electro-etching it in (peep the ancient electro-plater). Just used some adhesive vinyl, drew the star in place, and cut out the lines with a utility knife. Hooked up the electrodes and spent some time with an electrolyte solution on a paper towel. Ended up getting a fairly deep etch.

AND here is the result with some black paint sprayed into the cuts. Was really tempted to just leave it here because it looks so clean, but I did soon follow up with paint.

Duplicolor makes a lovely faux anodized enamel paint. Clear enough to see the metal texture, but with enough coats the color really pops. Its not the cleanest application, though. I was a little splotchy with the gloss, but ended up going over everything with steel wool in the end to give it a matte look.

Final shots! Went over everything with a clear enamel to prevent rust and another round of steel wool. Didn't do much with the back of the shield as this ended up being a wedding present and there was a deadline closing in (also forgot to take pictures of the back before giving away). Welded the brackets on earlier in the build and finished up come leather belts for straps.

Very pleased with how it turned out. Lines are clean, colors are great, but it is VERY heavy. Would love to try again with a thinner stainless steel disc, may be able to get ahold of a vessel head fabricator in my line of work, but that will be costly.

Hopefully this project may prove to be useful to any garage builders like myself. I had some tools that made it easier, but anyone with a welder, grinder, and looks into electo-etching could do this from home with some patience. Let me know what you think!