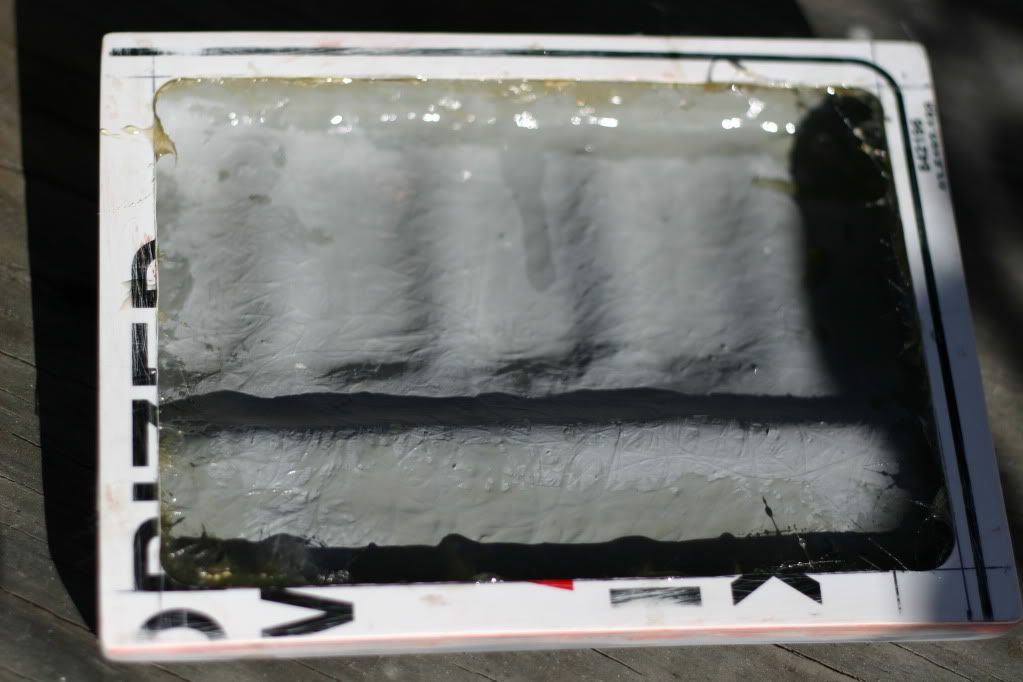

Since I'm using sign plastic it's important to reinforce it from the inside because it is flexible. You don't want your seams coming apart.Cut strips of fiberglass mat and brush inplace. I imagine if you can't fiberglass you can probably add hot glue (don't melt the plastic) or blobs of 5 min epoxy.

Once cured, sand and clean for priming.

Once primed look for pits and gaps then fill. Sand and reprime.

UPDATE ON LEG RIGGING

If you look at my very first post you'll see how I'm using bunjee cords hooked at the shin knee and hooked to the top of the thigh. After trying the shorts on there wasn't much room for that. This is from what I gathered is the way most builders attach their bujee cords. But for me it's not working out.

Using the same bunjee cords and wheels for a sliding screen door (home depot) and we will try to do it simular to how AD's suit is.

Remove the wire binder from both ends of the cord. Bring the two ends together and make a doughnut. Use the wire from the hook to bind the ends together.

Since you already have a bolt attached to your knee greeblie simply install one of the wheels and use a washer.

For me I have already fiberglassed in the hooks for the other side so I'll use those for now. The wheels come with bolts so you can fiber glass those in for the other areas.

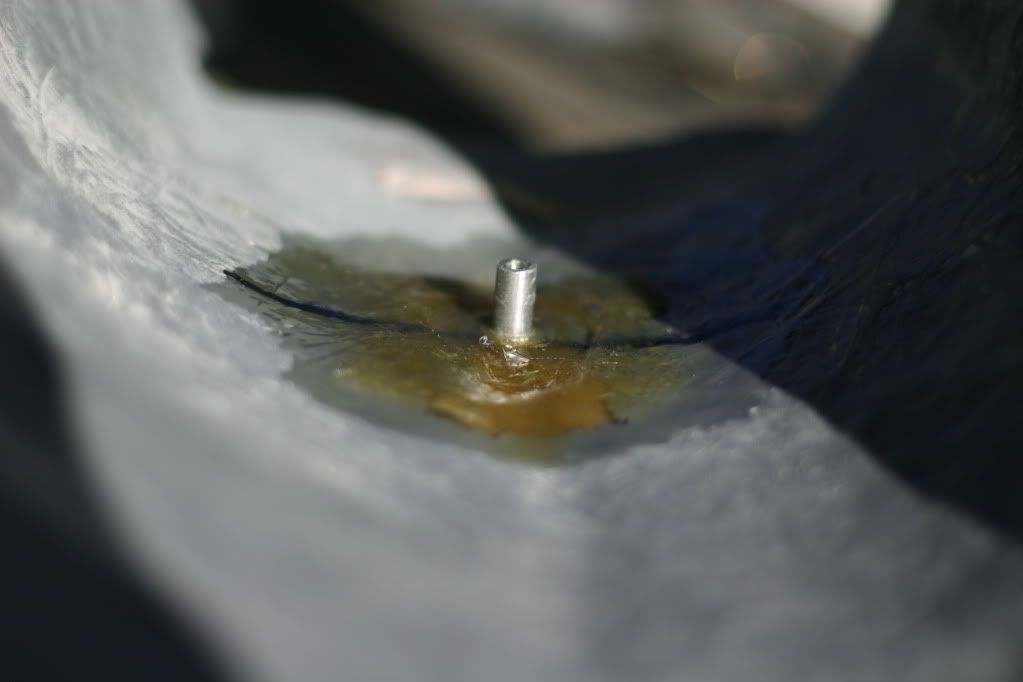

Before you install the wheels in the thighs you might want to try on the shorts and thighs together to determine where they can fit. You don't have to go up high. Once you determine where they will go, remove the primer in that area by sanding And mark the placement with a Sharpie. Before you fiberglass, cut a small square from mat, cut a hole and insert the provided stem from the door wheel. Brush on your resin, place another precut square over the resin, brush resin on then place the stem and mat on, followed by smaller strips of mat aroung the stem.

You may want to trim the stem with the wheel in place before you fiberglass it in place. You might need the room.

As you can see the stem is protruding over the wheel. I'll trim it later. I also plan on gluing each wheel down on the surface of the fiberglass to take the stress off of the stem.

Attach the bunjee and screws and your set. If the bunjees slip off of the wheels you can always glue plastic circles to the top of the wheels.