You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bowcaster Build - I think I’m ready?

- Thread starter Cameron

- Start date

russellsch

Master Member

Holy cow, I don’t think I’ve ever seen the “hidden“ screw on the left plate!

I love this thread.

I love this thread.

Those knobs look spot on!! Awesome kit there!!! I’d love to have that hanging on my wall lol. Progress looks fantastic!

I think any cutting compound would work after a 2000 / 4000 grit wet sanding. Maybe try the wetsanding first with the highest grit? If it’s only a few layers, you could just polish right through it though

Anyway keep up the good work!!

I think any cutting compound would work after a 2000 / 4000 grit wet sanding. Maybe try the wetsanding first with the highest grit? If it’s only a few layers, you could just polish right through it though

Anyway keep up the good work!!

russellsch

Master Member

Oh man, that is quite lovely

My pleasure Dan. Sharing keeps me at it!Thanks for this thread - I'm about ready to begin my assembly and this is a great illustrated tutorial!

Looking good!

Dan

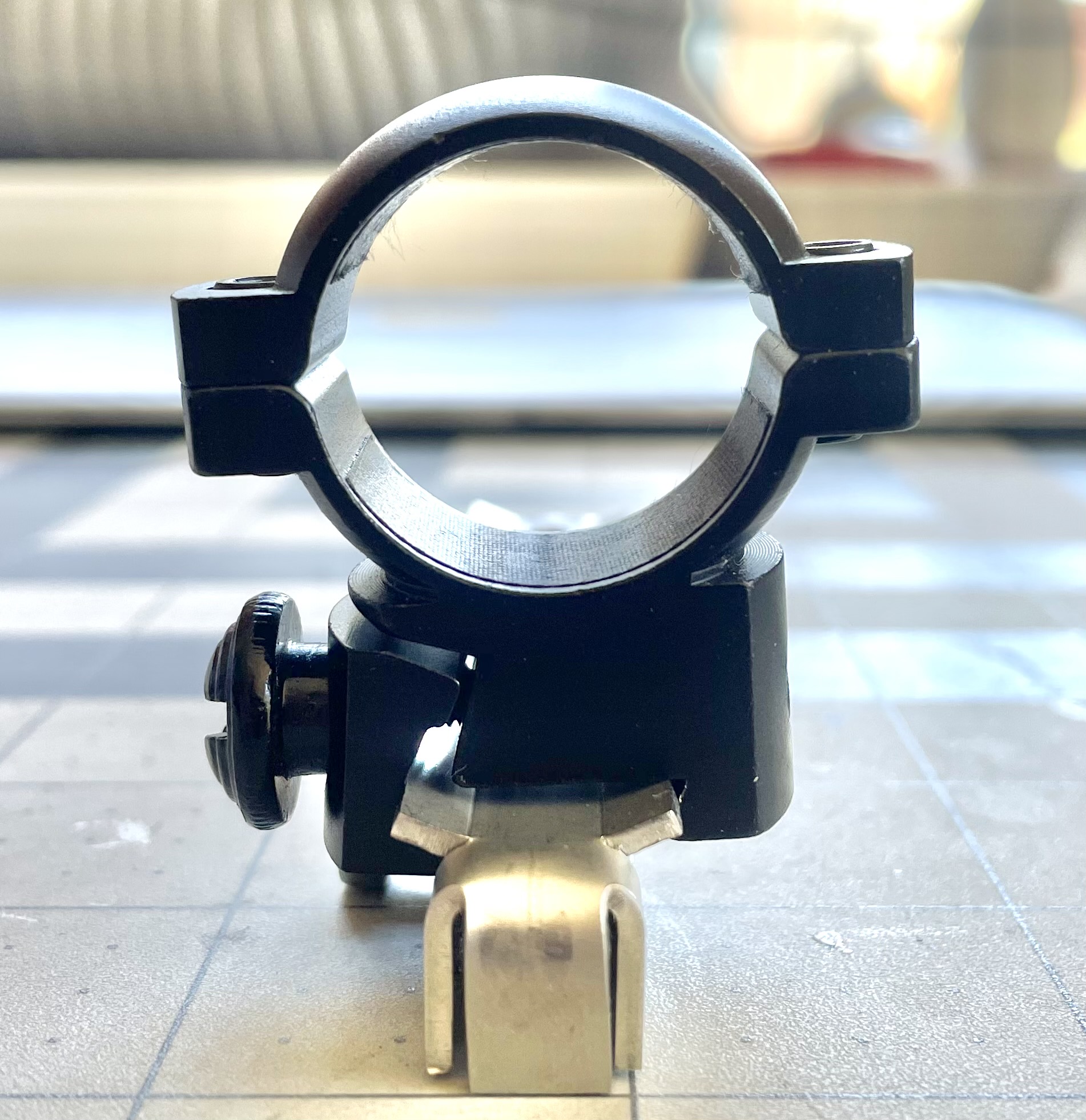

In test fitting parts I came upon a challenge. I can't get the scope rings for the Singlepoint to align straight on the scope rail. Its hard to see on this picture but it is shifted by a fair amount. This matters because the side scopes attach to these rings and they will be very tilted. Ive considered several ways to correct this but I thought I'd throw it out to the group. The only fix I can think of is to grind down the scope rail flaps. Jawajawa827

Your build looks awesome so far Cameron! In terms of the tilting, since the flaps are bent to the exact same angle on both sides and the rings (even the ones I have) seem to have different cut heights is what causes the tilt. I'm almost certain that the original has this tilt since I think the flaps are bent to the same angle on the original bow as well. (If someone who has the original bow wants to say if there is a tilt or not that would give us the answer).

As far as correcting the tilt if desired, the easiest way would be to bend the left flaps (side that doesn't have the tightening dial) down a slight bit. To do that place the mount in a vice gently with the left flaps up above the edge of the vice and using 1-2 (enough to fully cover the flap) adjustable wrenches slowly bend each flap down.

Hope that helps

As far as correcting the tilt if desired, the easiest way would be to bend the left flaps (side that doesn't have the tightening dial) down a slight bit. To do that place the mount in a vice gently with the left flaps up above the edge of the vice and using 1-2 (enough to fully cover the flap) adjustable wrenches slowly bend each flap down.

Hope that helps

Hmm. I’m thinking the flap on the left gets bent up not down?

What is the thickness of the material, that the scope rail is made of?

The original is quite thin with about 0,064"

My first approach would be to reduce the thickness at the spot, where the scope rings attach.

My second approach would be to reduce the width a bit.

But be assured, that even on my real BC, the scope rings are not dead center on the rail

The rail is .05" so its thinner.What is the thickness of the material, that the scope rail is made of?

The original is quite thin with about 0,064"

My first approach would be to reduce the thickness at the spot, where the scope rings attach.

My second approach would be to reduce the width a bit.

But be assured, that even on my real BC, the scope rings are not dead center on the rail

Im not so concerned with it being dead center on the rail. The problem is the deviation from center on the radial axis. This attachment point thows off the attached scopes by about 10 - 15 degrees. I will try some bending.

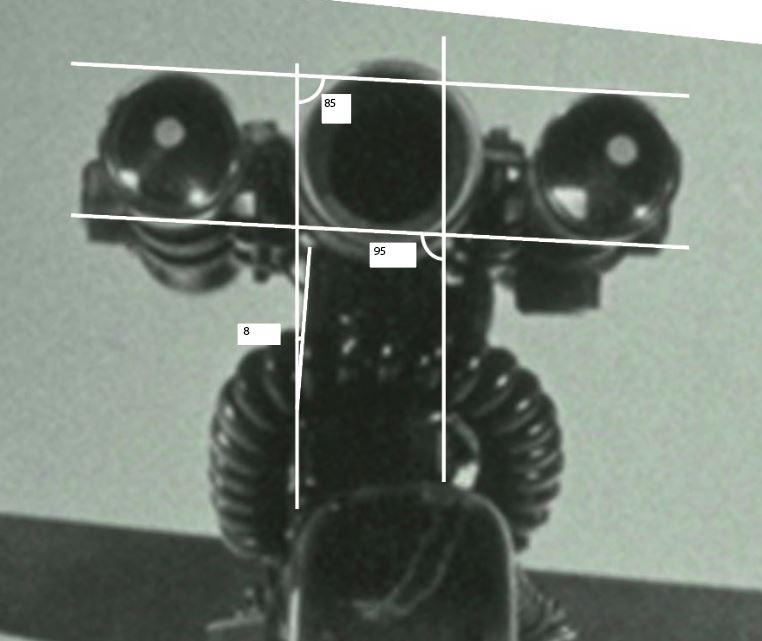

I drew this up in illustrator, the degrees may be slightly off but it shows the tilt on the bowcaster.

Hope this helps

Hope this helps

I did the same thing. But overall I’m not looking to replicate that pictures tilt because I think it may be exaggerated by some of the camera angles and the prod being off the center line.I drew this up in illustrator, the degrees may be slightly off but it shows the tilt on the bowcaster.

Hope this helps

View attachment 1506829

Awesome build, love this! If you're still struggling with the sheen, you might try a coat of shoe polish (I like the clear from Kiwi). Shines stuff right up, I'm using it on lots of things these days. You get a more "lived in" look than paint, which looks like...paint.

Similar threads

- Replies

- 50

- Views

- 7,654

- Replies

- 9

- Views

- 730

- Replies

- 57

- Views

- 4,590

- Replies

- 49

- Views

- 7,349