Archive&Future

Sr Member

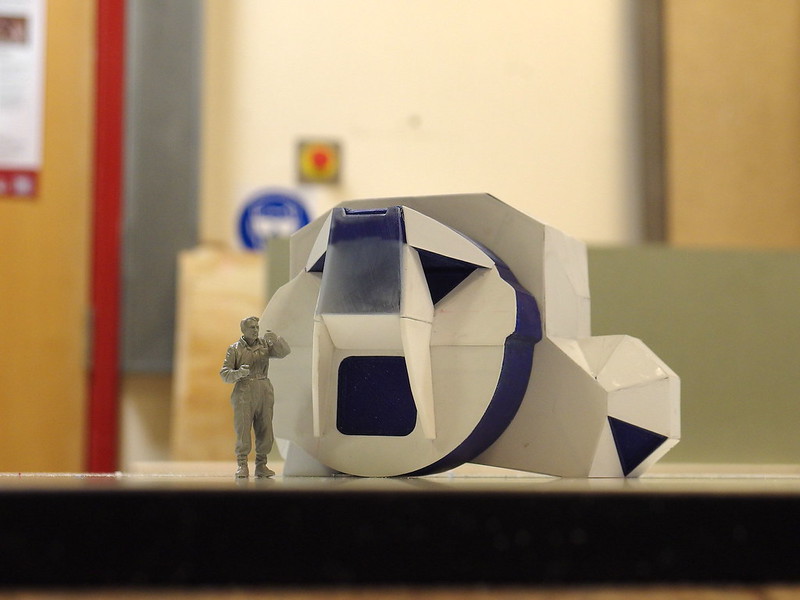

This afternoon I began to create the egress column.

This was hand-cut with help from templates I printed using an unfolding plugin for Sketchup; although as is usually the case nothing went together perfectly and I resorted to old-school measuring and fitting by eye.

This was hand-cut with help from templates I printed using an unfolding plugin for Sketchup; although as is usually the case nothing went together perfectly and I resorted to old-school measuring and fitting by eye.